Plug-flow distribution type sewage treatment device

A sewage treatment device and plug-flow technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve waste, high labor intensity, difficult to accurately control the amount of input, etc. problems, to achieve the effect of avoiding waste and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention.

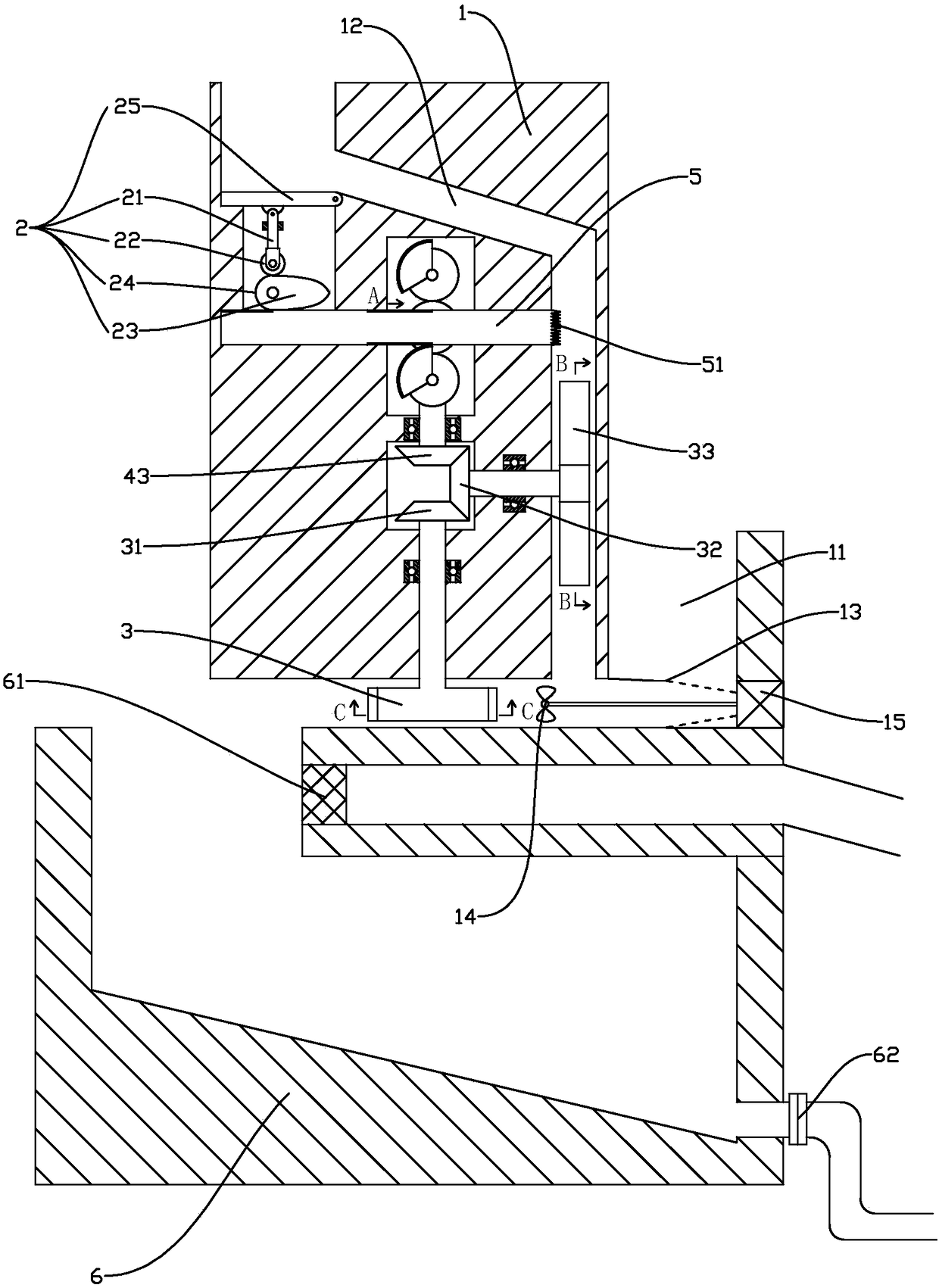

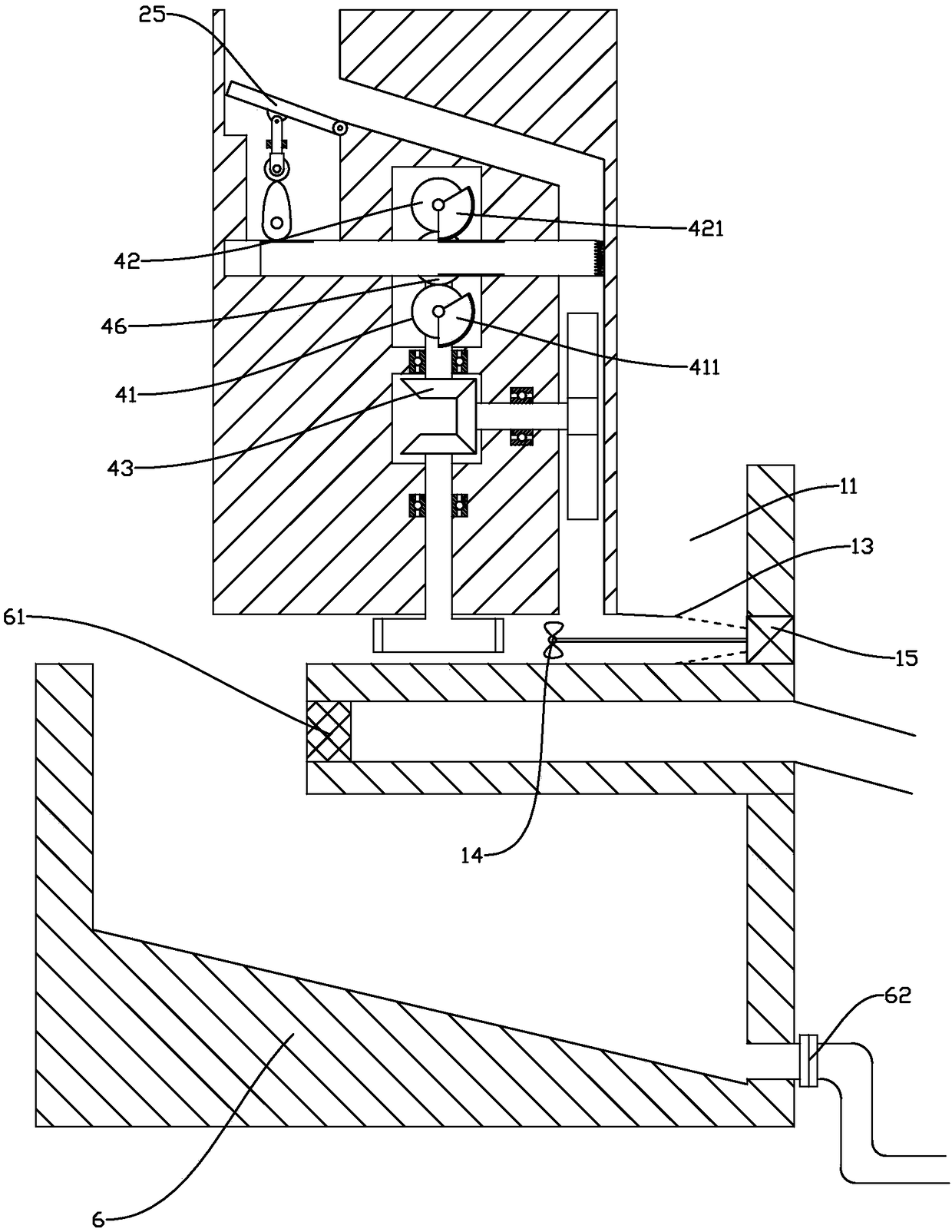

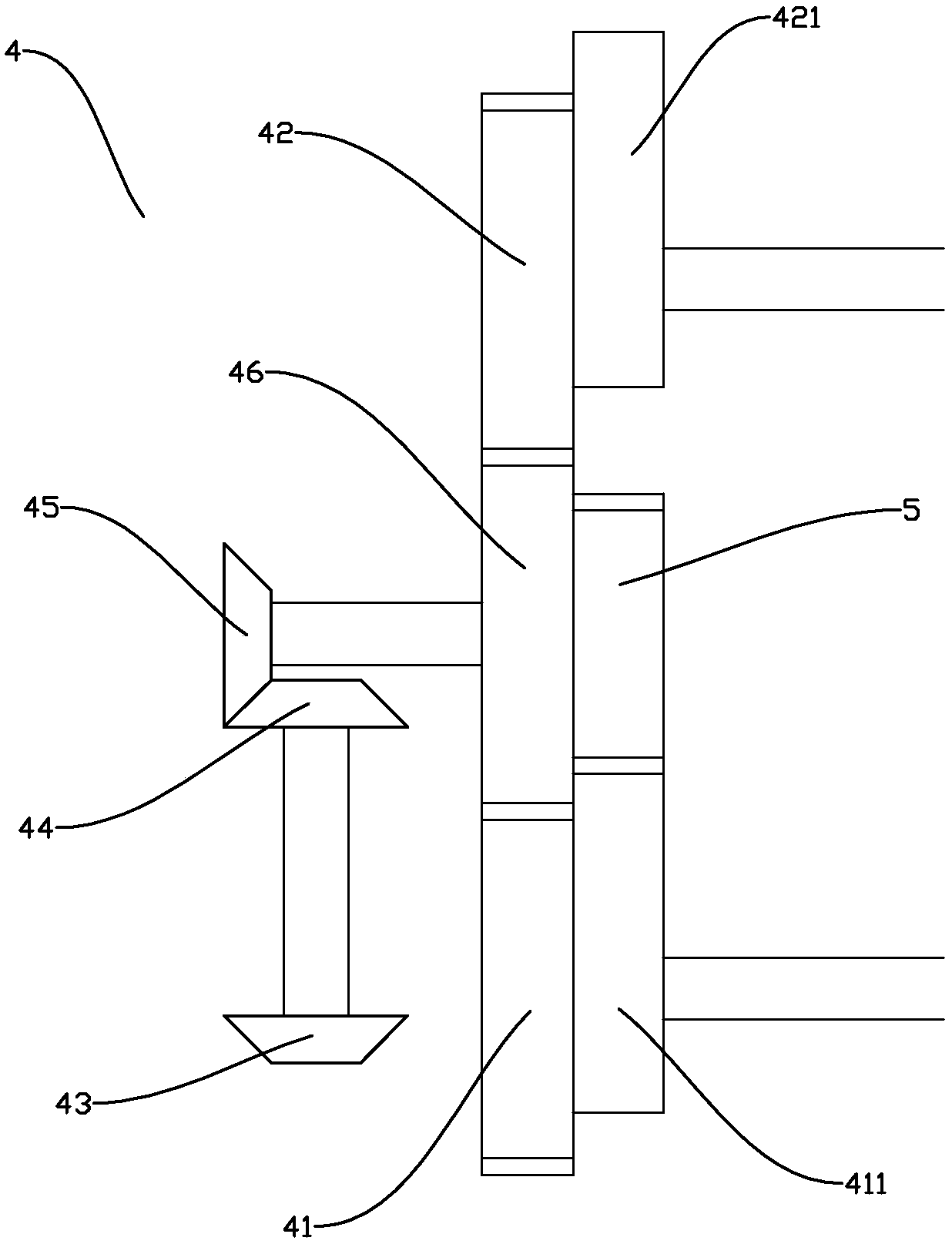

[0020] Such as Figure 1~5 As shown, according to a preferred embodiment of the present invention, it includes a substrate 1 provided with an alum treatment chamber 12 and a sewage inlet 11 located below the substrate 1. The bottom of the substrate 1 is provided with an impeller 3 driven by sewage to rotate. The impeller 3 is coaxially connected to the first bevel gear 31 meshing with the second bevel gear 32 on the side close to the base 1, and the second bevel gear 32 is coaxially connected to the alum gear located on the side close to the sewage inlet 11. The crushing wheel 33 in the treatment chamber 12, the second bevel gear 32 controls the rack 5 above the crushing wheel 33 to perform linear reciprocating motion through the transmission mechanism 4, and the upper and lower sides of the rack 5 are provided with toothed Structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com