Equipment for preventing filler in MBBR (Moving Bed Biofilm Reactor) pond from flowing into secondary sedimentation tank

A secondary sedimentation tank and equipment technology, which is applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of reducing the biomass of the ecological filter bed and affecting the separation effect of mud and water in the secondary sedimentation tank , blocking the sludge return pump of the secondary sedimentation tank, etc., to achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

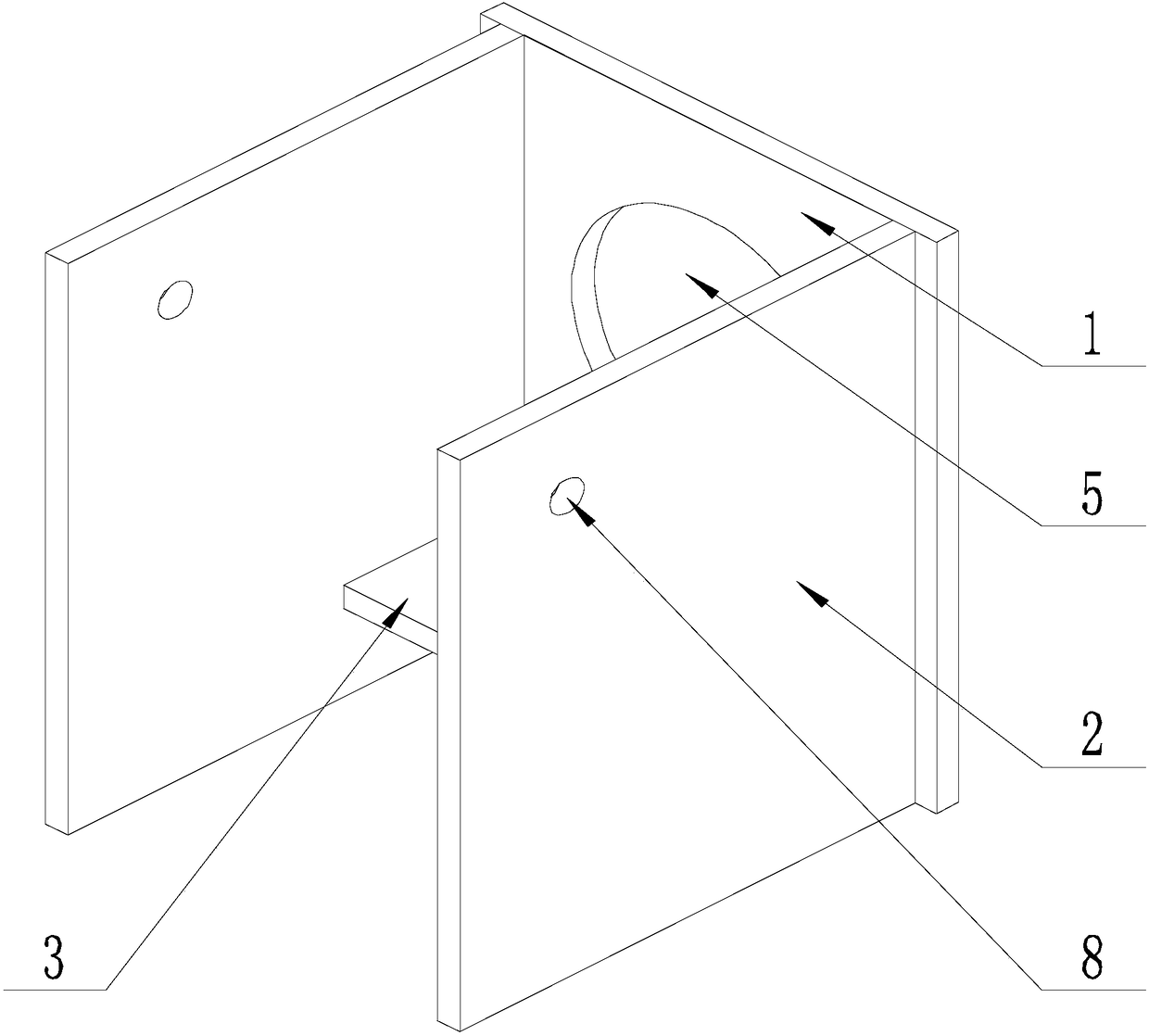

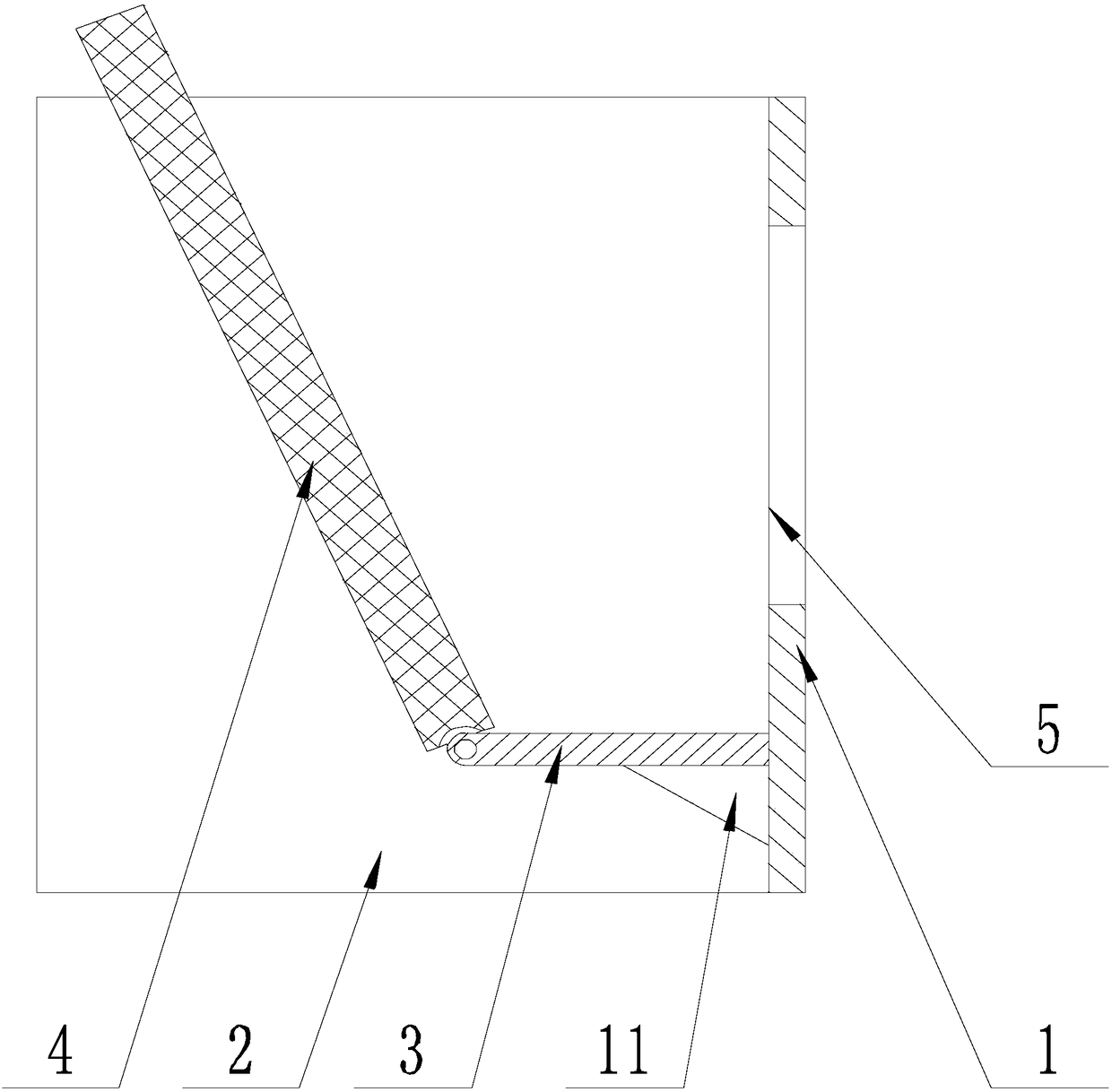

[0030] like Figure 1-Figure 4 As shown, the present invention prevents that the filler in the MBBR tank flows into the equipment of the secondary sedimentation tank, comprising a fixed plate 1, a support plate 2, a connecting plate 3 and an inclined plate 4, and a drain hole 5 is arranged on the plate surface of the fixed plate 1, so that The axis of the drain hole 5 is perpendicular to the fixed plate 1, the support plate 2 has two, and the support plates 2 are parallel to each other and perpendicular to the fixed plate 1, one end of the support plate 2 is connected with the fixed plate 1, and the drain hole 5 , the connecting plate 3 and the inclined plate 4 are all located between the support plates 2, the connecting plate 3 is perpendicular to the fixed plate 1 and the support plate 2 at the same time, one end is connected with the end of the plate surface of the fixed plate 1 near the bottom surface, and the other end is connected with the bottom surface of the fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com