Novel photothermal salt sun-drying accelerating method and device

A thermal insulation device and photothermal technology, applied in the direction of alkali metal chloride, energy input, etc., can solve the problems of slow evaporation of water, restrictions on the development of sun-dried salt enterprises, low production efficiency and production benefits, and achieve the effect of preventing surface salt precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

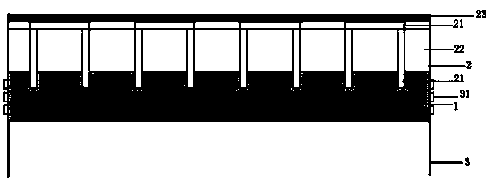

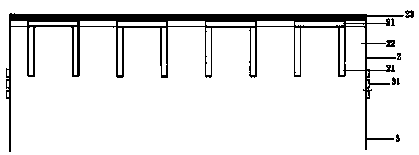

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted here that the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute conflicts with each other.

[0029] The efficiency of drying salt is mainly determined by the speed of water evaporation, and the evaporation of water mainly depends on the speed of water temperature in addition to the ambient wind speed and temperature and humidity. The present invention utilizes the principle of increasing water temperature, uses photothermal materials to heat seawater on the surface of the material, and rapidly increases the temperature of seawater to increase the efficiency of salt production.

[0030] The present invention discloses a novel photothermal accelerated salt drying method, comprising the following steps:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com