Insulated operation rod with electric wrench

A technology of insulated operating rods and electric wrenches, applied to wrenches, motor tools, overhead lines/cable equipment, etc., can solve problems such as economic losses, obstacles to maintenance work, and low operating efficiency, so as to reduce economic losses and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

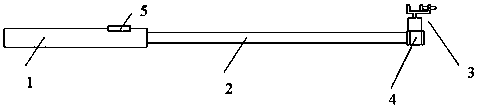

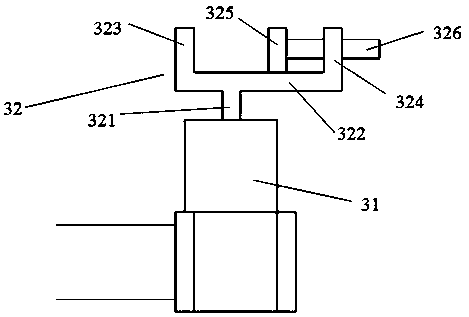

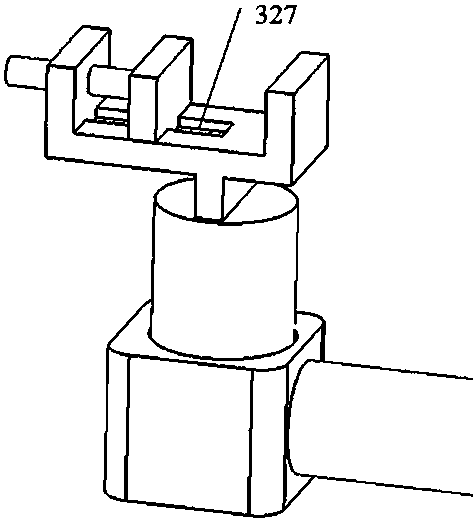

[0023] This embodiment provides an insulating operating rod with an electric wrench, such as figure 1 As shown, it includes a control circuit, a handle 1, a telescopic rod 2, and a rotatable wrench assembly 3. One end of the telescopic rod 2 is connected to the handle 1, and the other end is provided with a mounting head 4, which is fixedly connected to the wrench assembly 3; the wrench assembly 3 includes a rotating head 31 and a wrench head 32 that can automatically adjust the tightness; the handle 1 is provided with a control switch 5, and the control switch 5 and the wrench assembly 3 are electrically connected to the control circuit. The installation head 4 is installed and matched with the wrench assembly 3, and is fixedly connected. The working state of the wrench assembly 3 is controlled by the control switch 5 on the handle 1 through the connection of the control circuit, and the rotation and tightness can be adjusted. The telescopic rod 2 is the key to realize the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com