Self-positioning tool structure for assembling loop network switchgear cubicle instrument box

A technology for switch cabinets and instrument boxes, which is applied in the field of self-positioning tooling structures, and can solve problems such as large corner deviation, reduced production efficiency, and assembly molding dimensions that cannot meet molding accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

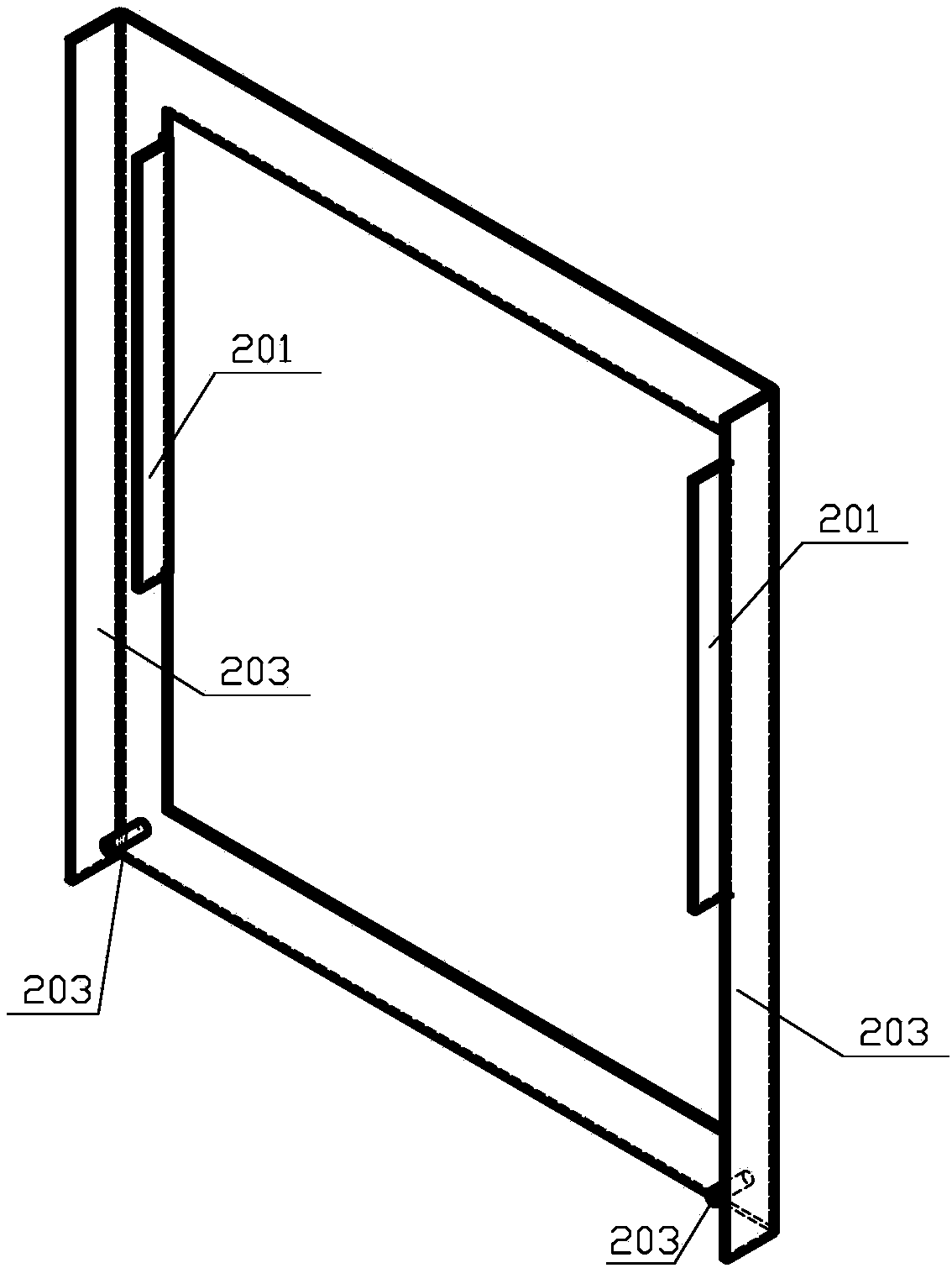

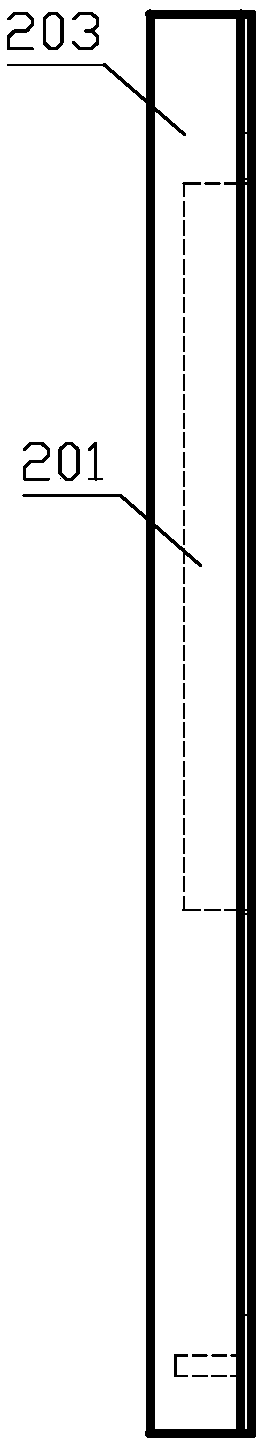

[0030] Figure 15 It is an exploded view of the overall structure schematic diagram of the present invention, Figure 16 It is a schematic diagram after the overall structure of the present invention is assembled, Figure 17 It is a schematic diagram before the left and right side plates are placed for the present invention. Such as Figure 15-17 As shown, the present invention provides a self-positioning tooling structure for the assembly of the meter box of the distribution ring network switchgear, including a positioning base plate 1, a positioning cover plate 2, a positioning rear connecting plate 3, and left and right side plates 4; the positioning base plate 1 is fixed with a positioning Latch 101; positioning cover plate 2 includes positioning flange 201; left and right side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com