A kind of outer circle ultrasonic honing device

An ultrasonic and honing technology, which is applied in the direction of honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of machining the outer circle of long-axis workpieces that cannot be changed in diameter, and achieve the effects of wide application range, reasonable structure, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

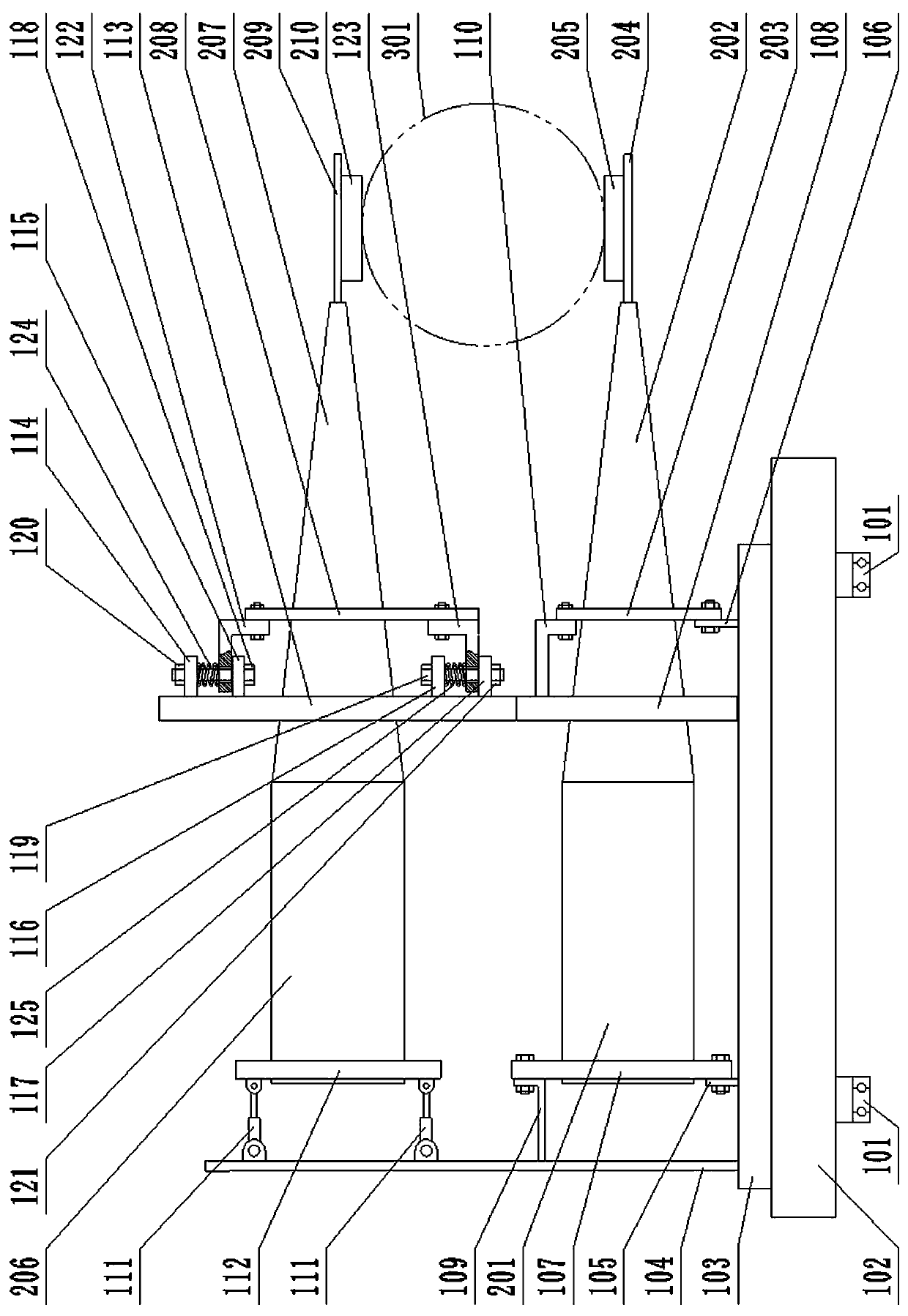

[0020] An outer cylindrical ultrasonic honing device, comprising a supporting part and a processing part;

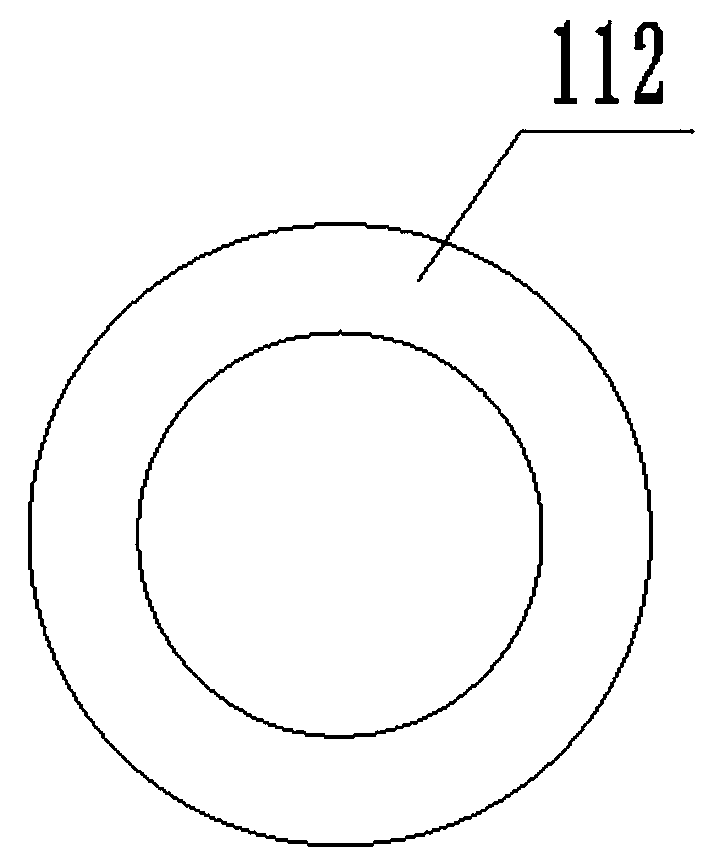

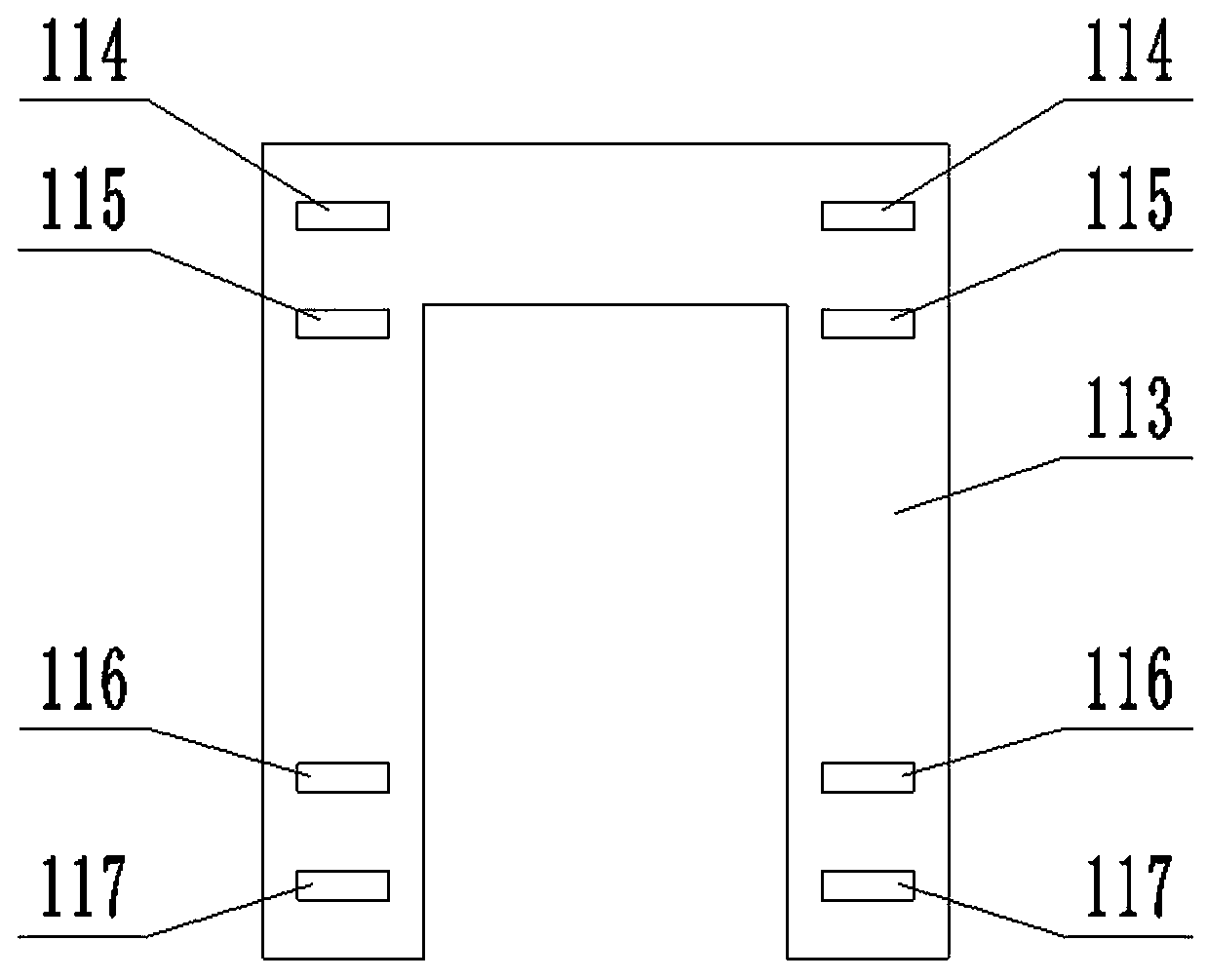

[0021]The supporting part comprises two horizontal guide rail pairs 101, a lower horizontal base plate 102, an upper horizontal base plate 103, a supporting vertical plate 104, a left limiting vertical plate 105, a right limiting vertical plate 106, a lower annular vertical plate 107, a lower Inverted U-shaped vertical plate 108, left L-shaped connecting plate 109, right L-shaped connecting plate 110, two telescopic rods 111, upper circular vertical plate 112, upper inverted U-shaped vertical plate 113, two upper horizontal ear plate groups , two lower horizontal ear plate groups, two upper fastening bolts 118, two lower fastening bolts 119, two upper fastening nuts 120, two lower fastening nuts 121, upper L-shaped adjustment plate 122, lower L Shape adjustment plate 123, two upper compression springs 124, two lower compression springs 125;

[0022] Each upper horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com