Automatic discharging device for automobile mold

An automotive mold, automatic technology, applied in the direction of launching equipment, etc., can solve problems such as inability to launch molds, safety hazards, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment, the present invention is further described, but the present invention is not limited to these examples, and under the premise of departing from the purpose of the present invention, any improvement for all falls within the protection scope of the present invention.

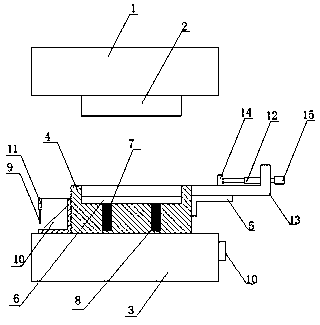

[0017] As shown in the figure, an automatic part ejecting device for an automobile mold according to the present invention includes an upper mold and a lower mold, and the upper mold includes an upper mold seat plate 1 and an upper punching die head 2. Installed on the lower end of the upper die base 1, the lower die includes a lower die base plate 3, a pushing device, a lower concave die 4, a transition device, and a support frame 5. The lower die 4 is installed on the upper end of the lower die base plate 1, so The transition device is installed on the left side of the upper end of the lower die base plate 3 , and the push device is installed on the right side of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com