Flower tea isolation scenting device and scenting method for reducing flower fragrance loss

A scenting device and scented tea technology, which is applied in the field of scented scenting devices isolated from scented teas, can solve problems such as the inability to effectively improve the utilization rate of flowers, the loss of flower fragrance, the unsatisfactory effect of tea fragrance absorption, and the extraction of gas, so as to improve the effect of fragrance release and avoid The effect of raising the temperature and fermenting mold and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

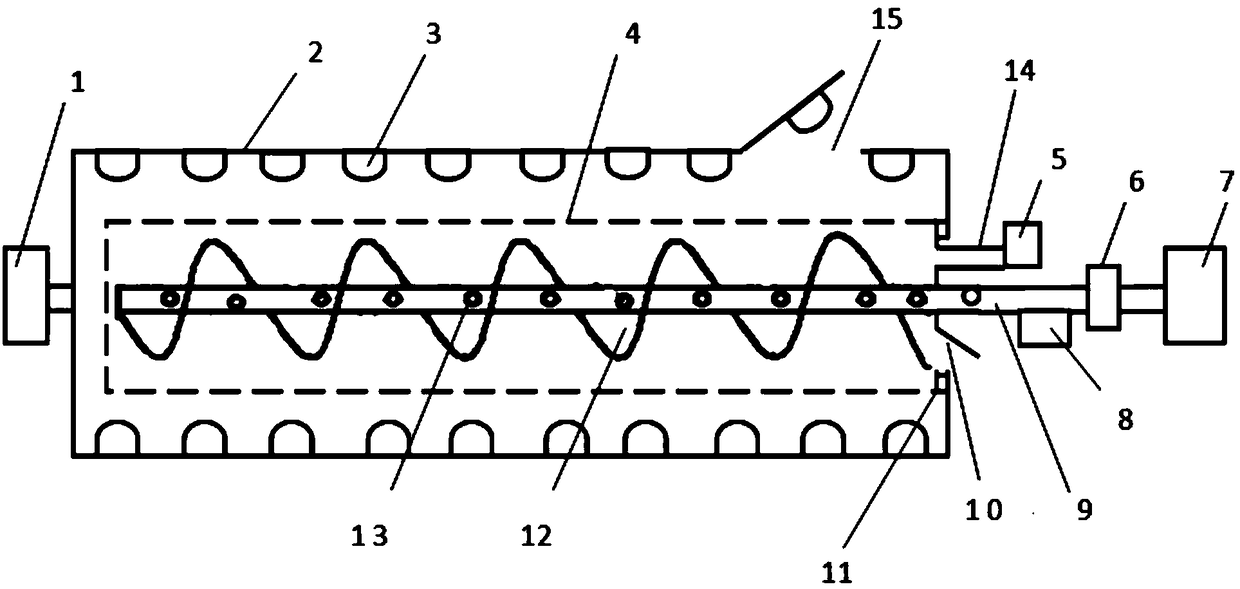

[0026] figure 1 It shows the specific implementation form of the scented scented scenting device that reduces the loss of floral fragrance according to the present invention, which includes: a net-like isolation scenting device 4, which is a net-shaped cylinder with no openings at the upper and lower ends, and in the center of the net-like cylinder The shaft runs through the shafted spiral blade 12, and the shaft of the shafted rotating blade is a hollow shaft 9, which is provided with air holes 13, and the hollow shaft 9 passes through the A end face of the mesh cylinder, and the second rotating motor 7 Drive the shafted rotating blade 12 to rotate through the hollow shaft 9; the shafted rotating blade 12 is made of heat-conducting material, a heater 8 is arranged on the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com