Asphalt slab ballastless track sub-rail foundation structure and quasi-static design method thereof

A ballastless track and infrastructure technology, applied in the field of rail transit, can solve the problem of no clear structural design method for the asphalt concrete track bed structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

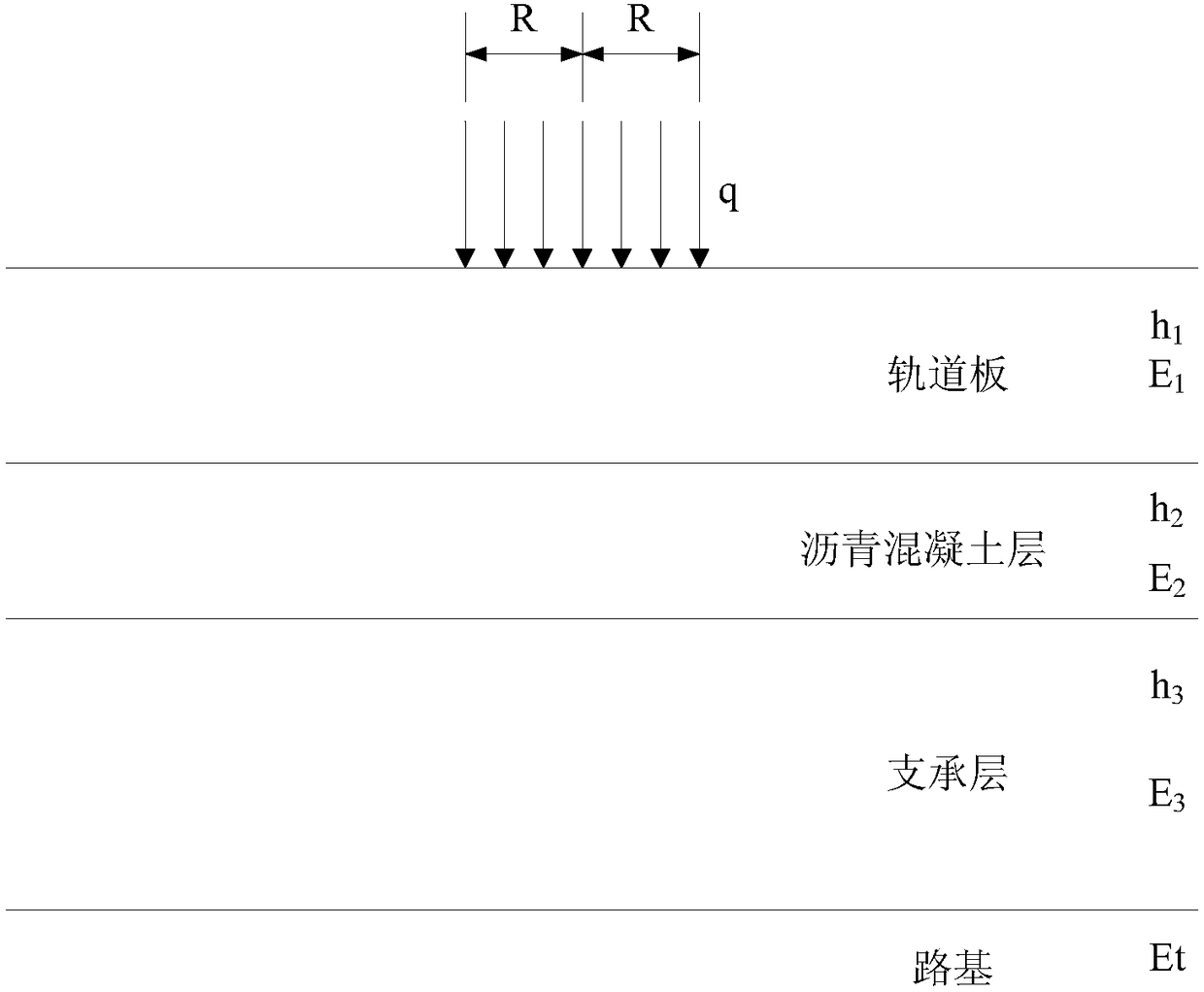

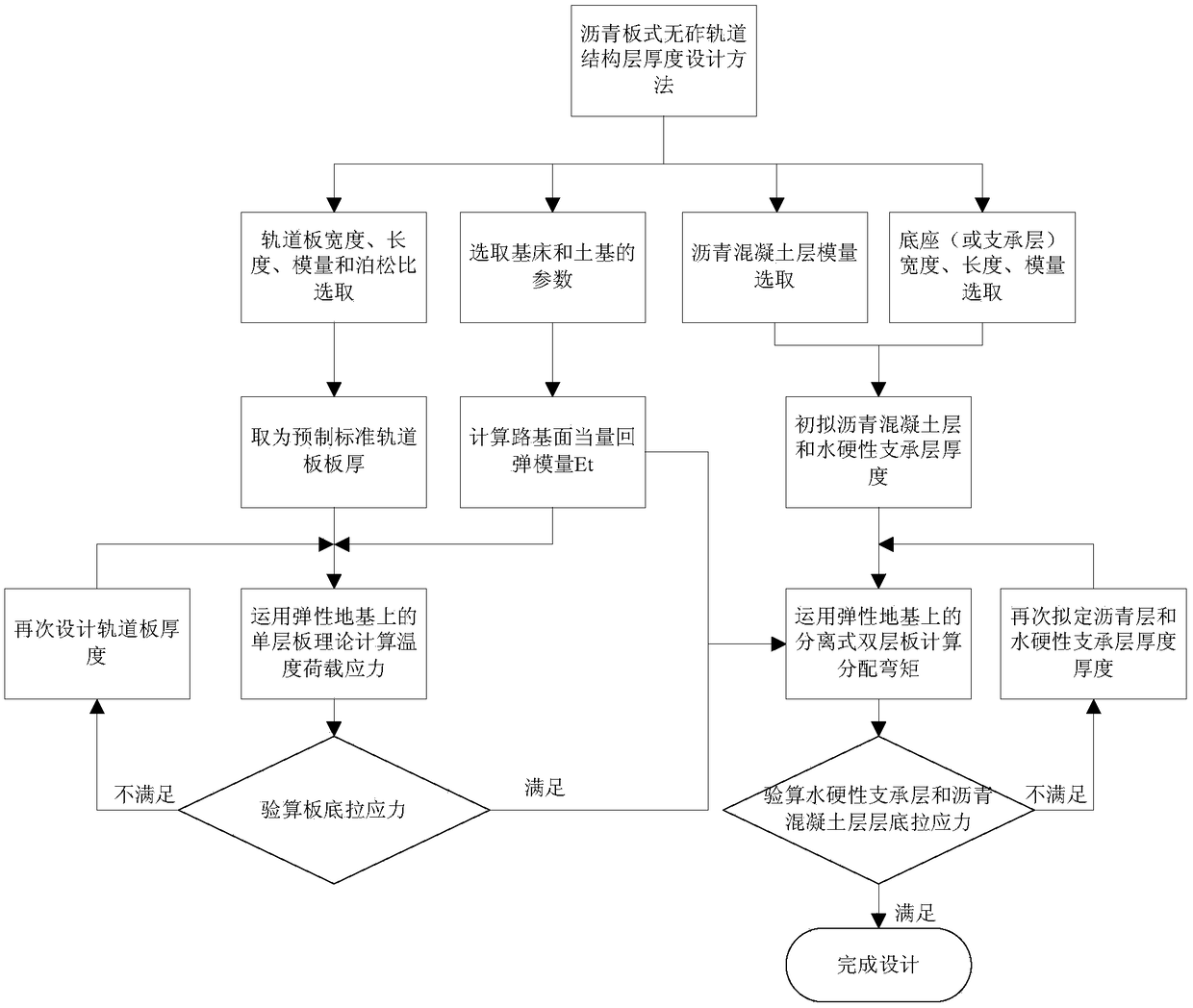

[0032] The under-rail foundation structure of the asphalt slab ballastless track of the invention is located above the surface layer of the ballastless track below the steel rail, and includes a three-layer layered structure of track slab-asphalt concrete layer-hydraulic support layer.

[0033] In order to control the fatigue damage, the control indexes of the bottom horizontal tensile stress of the track slab, the bottom tensile stress of the asphalt concrete layer and the bottom tensile stress of the hydraulic support layer are proposed.

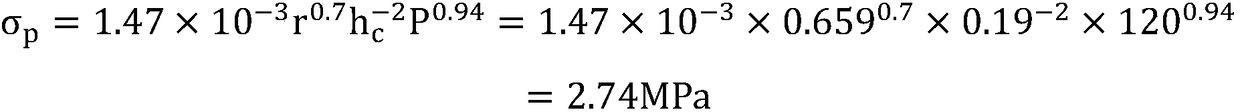

[0034] For example, the track slab is taken as a prefabricated unit slab, the length of the track slab is 5000mm, the width is 2400mm, and the thickness is 190mm for the CRTS I t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com