Single-side single-layer sewage processor

A sewage treatment, single-layer technology, used in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve the problems of limited backflushing water flow rate and general residue removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

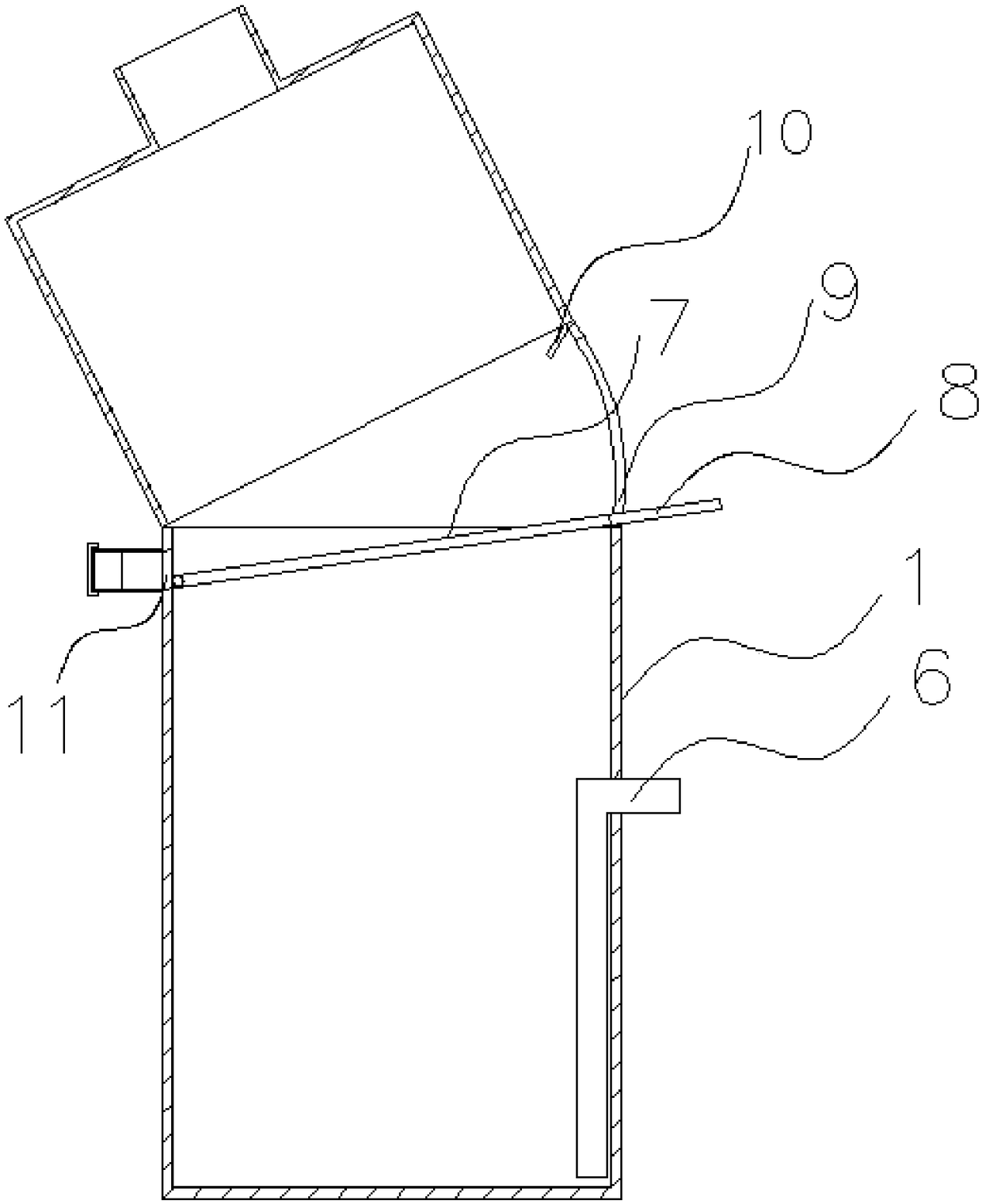

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The above-mentioned one-side single-layer sewage processor.

[0030] The single-side single-layer sewage processor includes: a cuboid lower treatment box 1 with an open upper end, two limiting plates 2 symmetrically fixed on the upper end of the lower treatment box 1 and having a fan-shaped structure, bridged between the two limiting The curved plate 3 between the curved sides of the spacer plates 2 and the upper treatment box 4 of a rectangular parallelepiped structure bridged between the two spacer plates 2 with straight sides.

[0031] The above-mentioned design provides the main structure in this embodiment, which includes: a lower processing box, a limiting plate, a curved plate and an upper processing box, wherein:

[0032]The lower processing box, the basic component in this embodiment, on the one hand, can install other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com