Preparation method of perovskite solar cell module

A technology of solar cell components and solar cells, applied in the field of solar cells, to achieve the effect of high implementation efficiency and satisfying industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

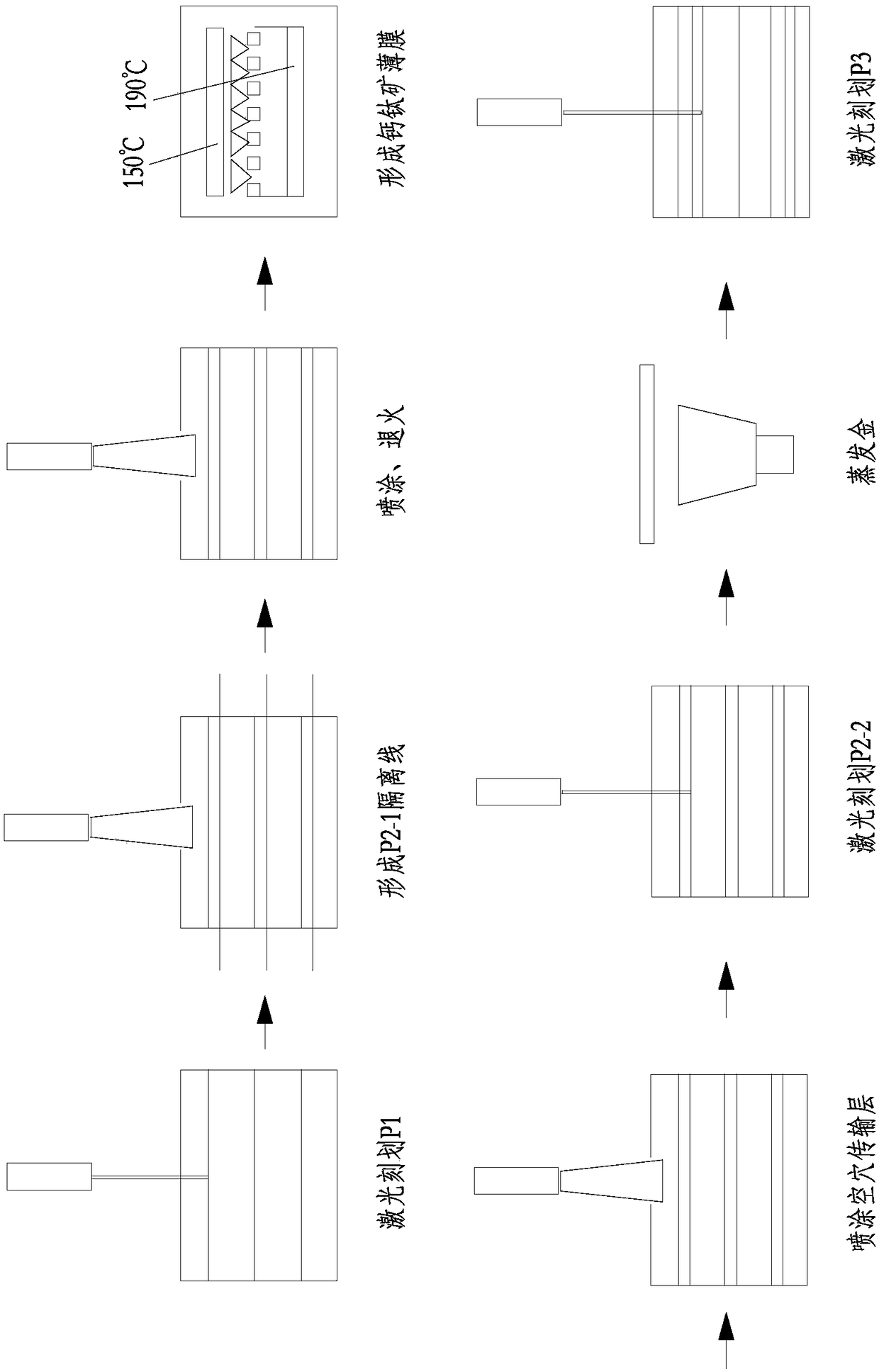

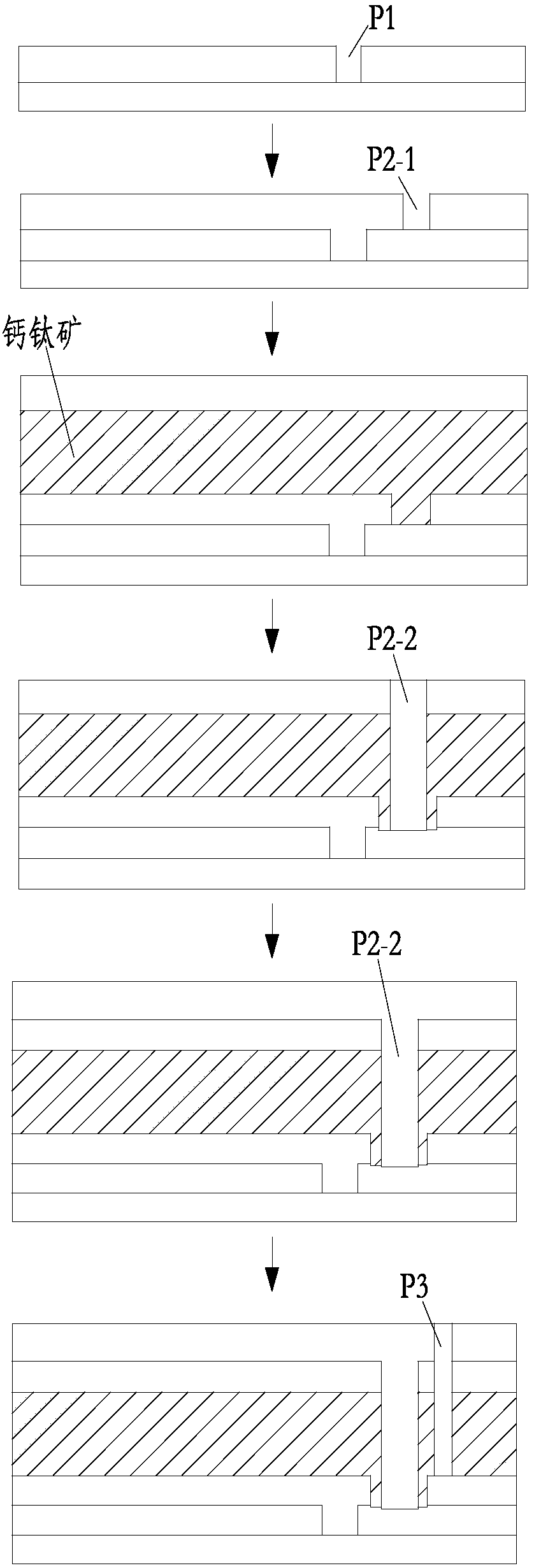

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] figure 1 , figure 2 Shown, a kind of preparation method of perovskite solar cell assembly has the following steps:

[0024] a. First, use a 532nm laser to draw the isolation line P1 on the FTO glass. The width of P1 is 100μm, and the distance between P1 is 1cm;

[0025] b. Tighten the scribed FTO glass with a stainless steel wire with a diameter of 100 μm on the upper surface, and stick it closely along the FTO surface. The distance between the stainless steel wire and P1 is 200 μm, and prepare titanium oxide or tin oxide by spray pyrolysis. Thin film with a thickness of 30-50nm, and then remove the stainless steel wire to form a P2-1 isolation line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com