Breaking hammer

A technology of breaking hammers and chisels, which is applied in construction maintenance, grain handling, earth movers/shovels, etc., can solve problems affecting crushing efficiency and achieve the effect of ensuring cutting positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

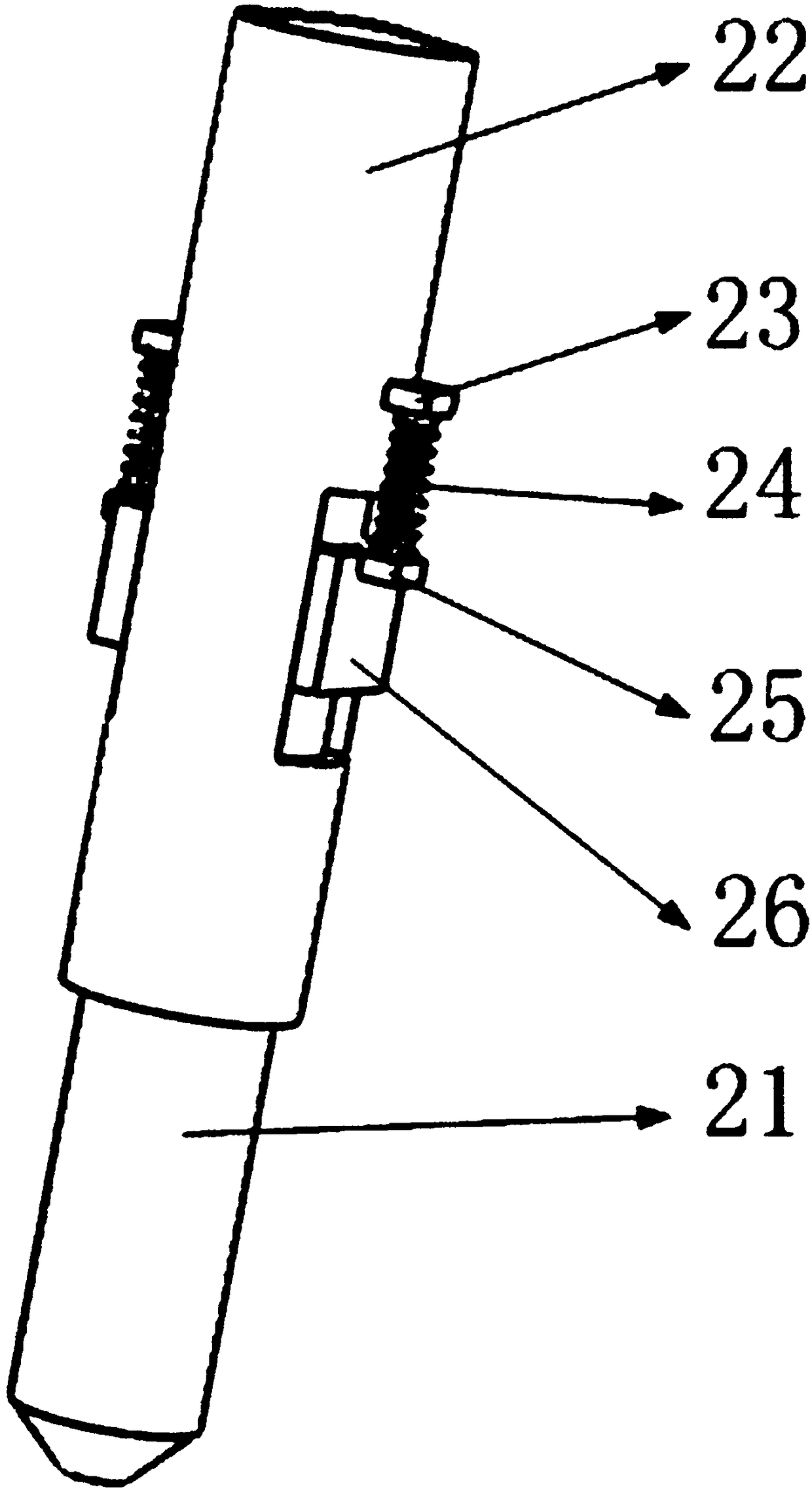

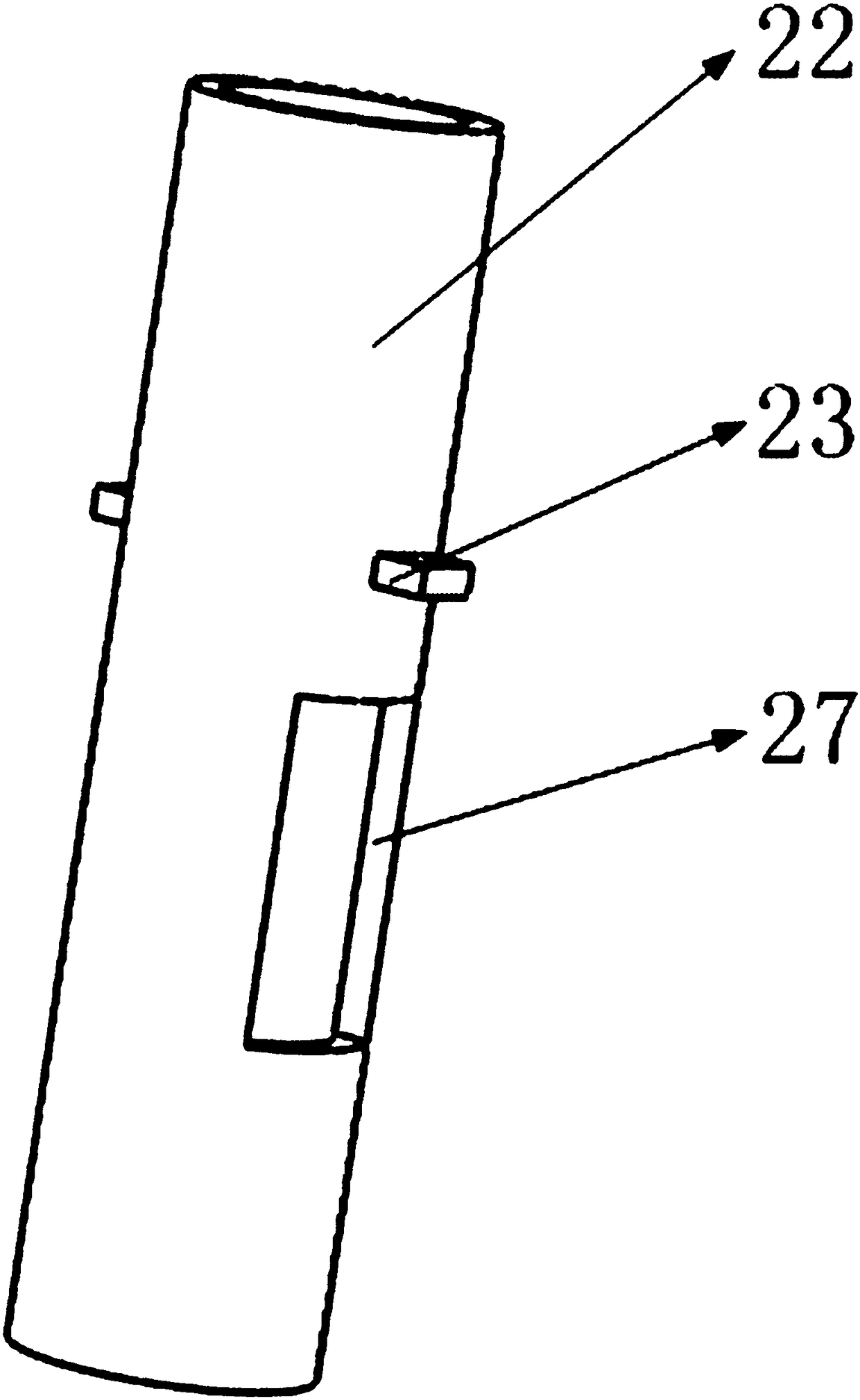

[0032] Such as Figure 17 , 18 As shown, it includes guide rail, rotary drive mechanism, spacer, spacer groove, thin wall support, ring plate support, cutting motor, cutting motor support, support plate, second gear, first bevel gear, drive shaft, brazing Rod, drill rod sleeve, first drill rod spring support, drill rod spring, second drill rod spring support, drill rod guide block, drill rod sleeve sliding hole, spring pin, second bevel tooth, first pulley, third gear , the first rotating shaft, the second pulley, the fourth gear, the first cutting wheel, the second rotating shaft, the second cutting wheel, the hydraulic support ring, the hydraulic rod, among which such as figure 2 As shown, there is a drill rod sleeve sliding hole in the lower part of the drill rod sleeve and runs through the entire drill rod sleeve. The two first drill rod spring supports are symmetrically installed on the drill rod sleeve and are located on the upper side of the drill rod sleeve slide hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com