Rocket lightweight efficient full-motion air rudder and manufacturing method thereof

An air rudder, lightweight technology, applied in the field of air rudders, can solve the problems of low bearing capacity, difficulty in meeting the design requirements of metal structures, and heavy structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is illustrated below through specific examples, but the present invention is not limited.

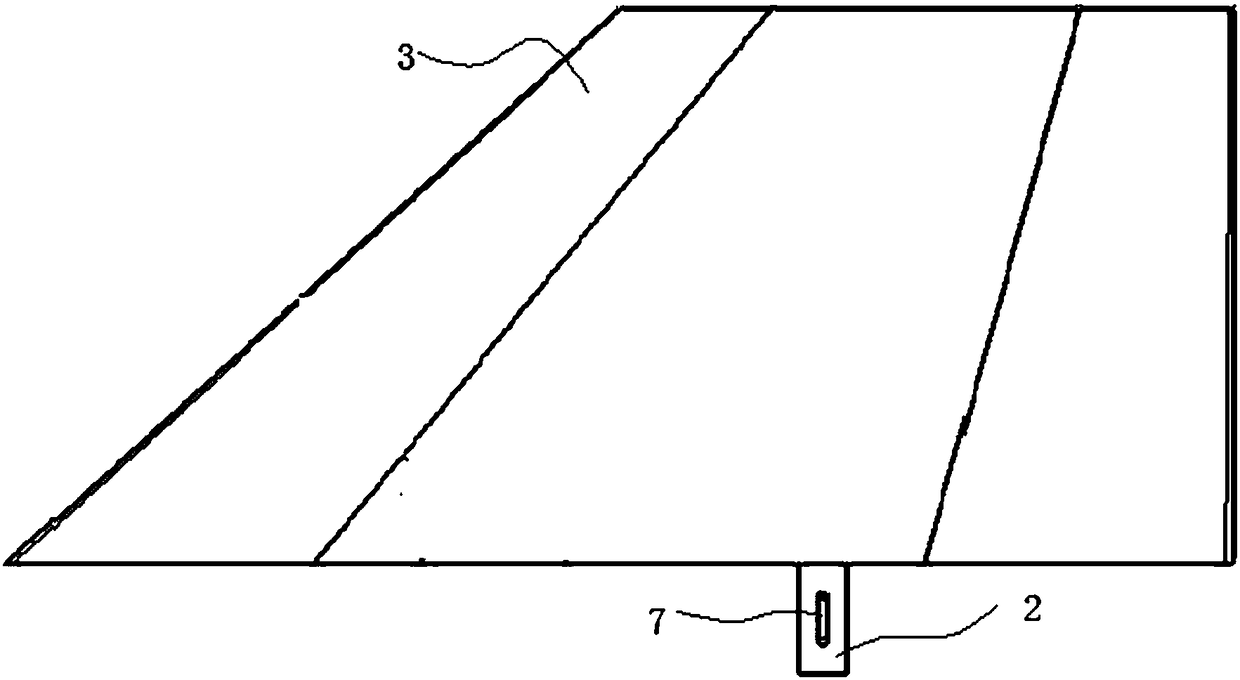

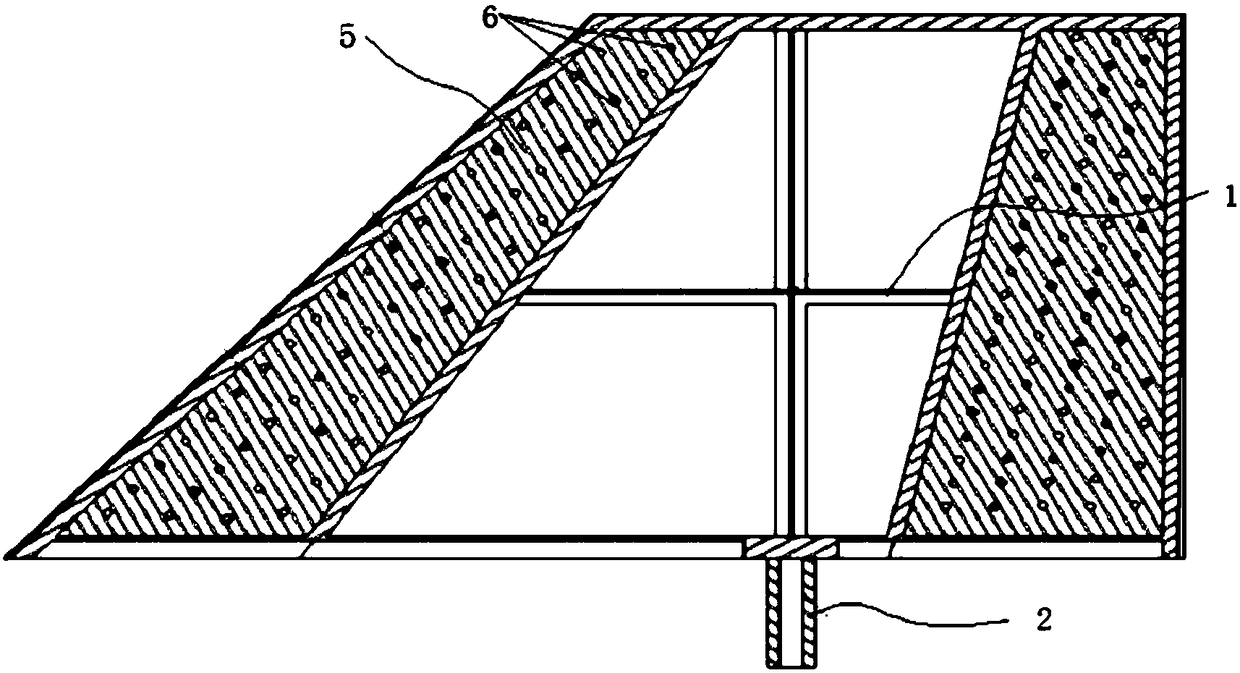

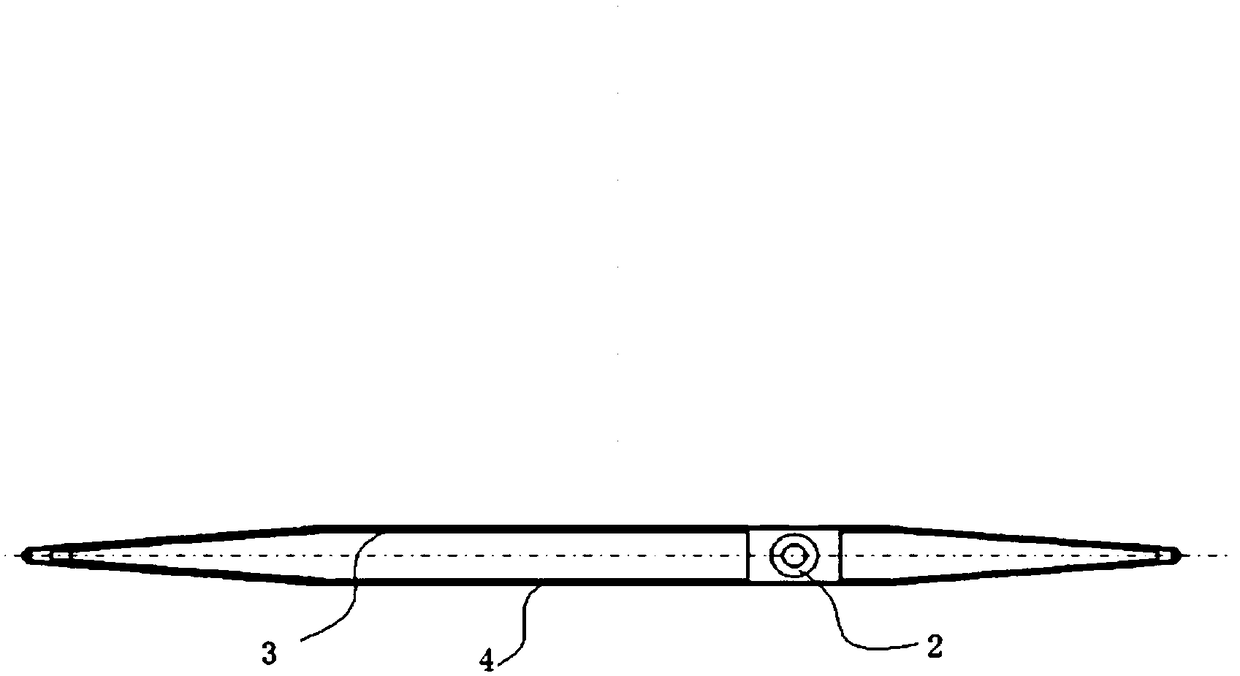

[0026] Such as Figure 1 to Figure 4 As shown, a rocket light and high-efficiency full-motion air rudder includes an air rudder body, and the air rudder body includes a skeleton 1 and a rudder shaft 2 connected to the skeleton 1. The left side of the skeleton 1 is provided with a left cover The skin 3 is provided with a right skin 4 on the right side of the framework 1; it also includes a foam interlayer 5 between the left skin 3 and the right skin 4, and a reinforcement 6 is arranged in the foam interlayer 5. Carbon fiber resin-based composite materials are used, and a foam interlayer is provided between the left skin and the right skin. The foam interlayer is provided with reinforcements, which greatly improves the load-bearing efficiency of the rudder surface structure.

[0027] Such as figure 2 As shown, the reinforcing member 6 is a reinforcing rod, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com