A Self-pitching Controlled Blade Turbine Optimized Based on Traditional Wells Turbine

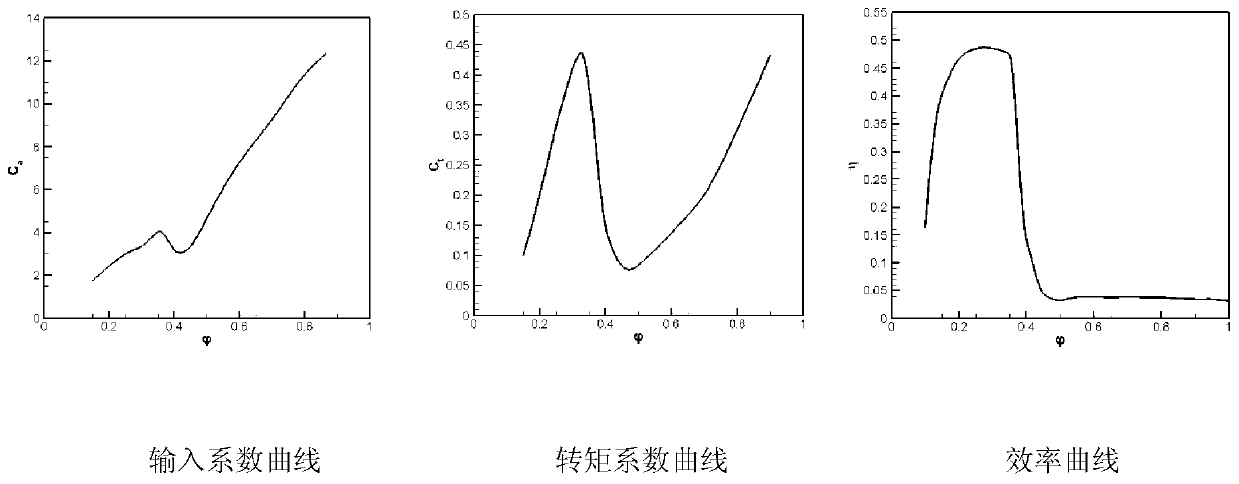

A Wells-style, pitch control technology, applied in the direction of machines/engines, mechanical equipment, ocean energy power generation, etc., can solve the problems of turbine performance deterioration, narrow working range, low peak efficiency, etc., and achieve good self-starting characteristics, The effect of high working efficiency and low working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

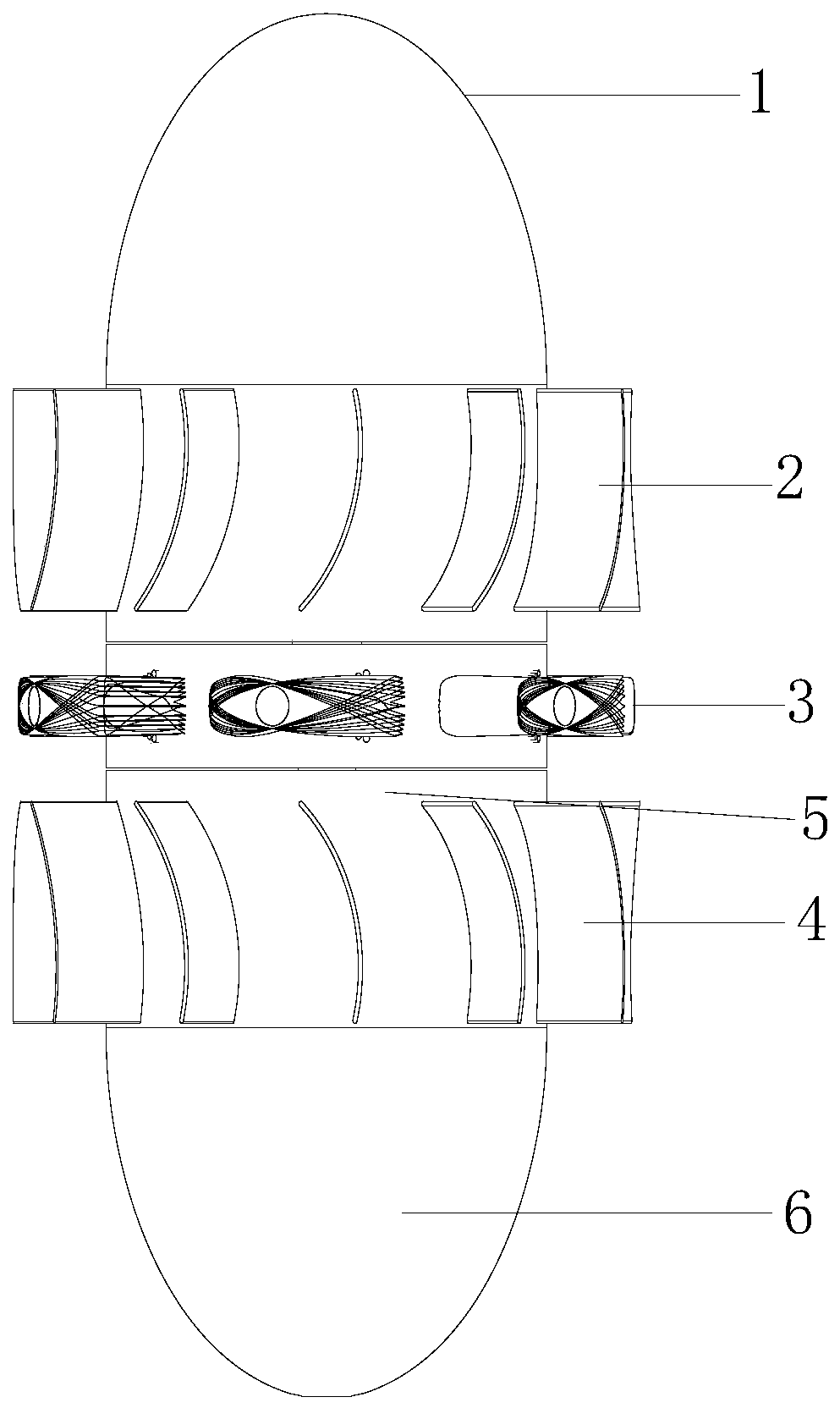

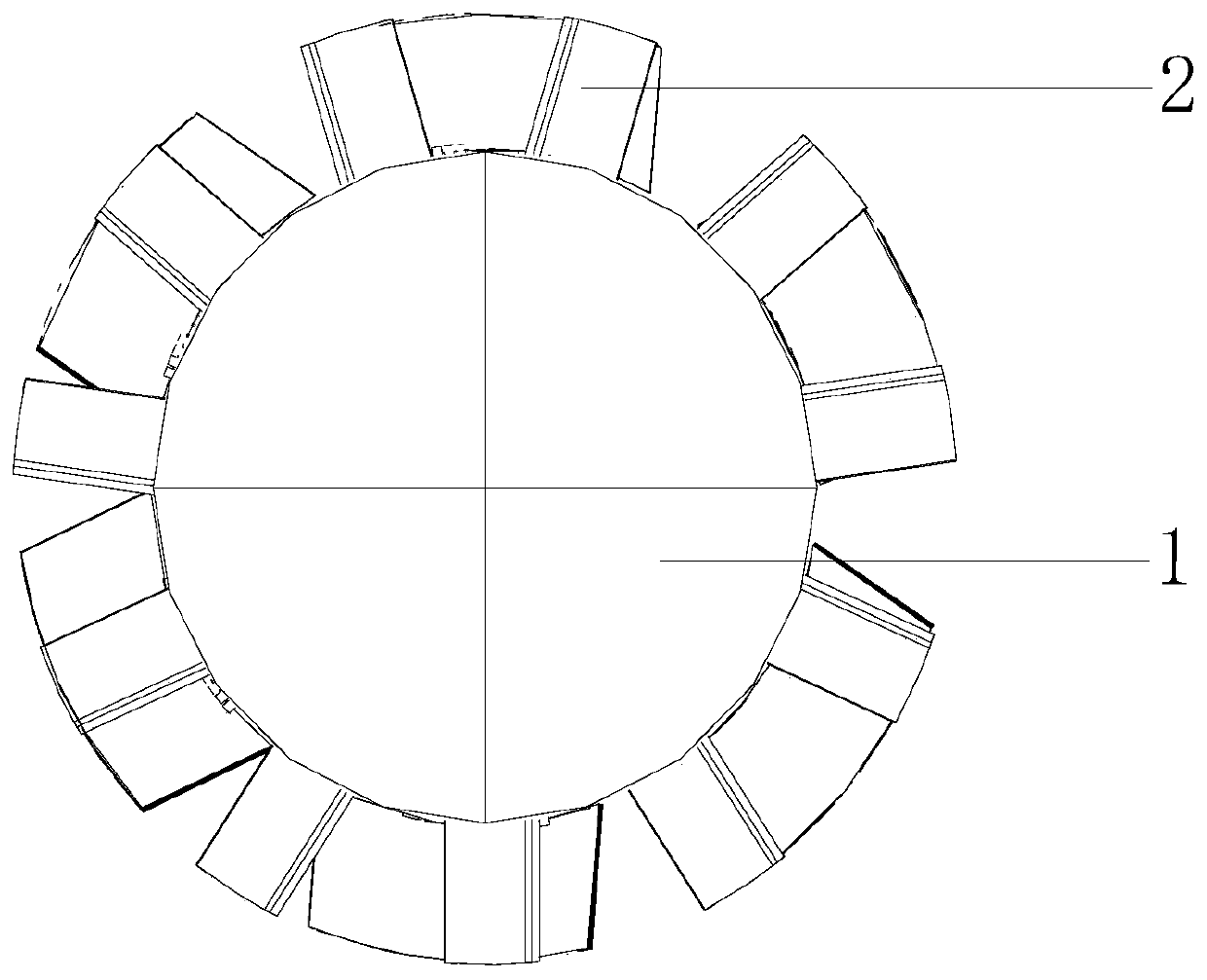

[0036] Example 1, such as Figure 2-5 As shown, this embodiment discloses a self-pitching control vane turbine optimized based on a traditional Wells-type turbine. The hub heads 1 and 6 of the mouth, the moving blade wheel 11 that can rotate around the hub is nested on the hub, such as Image 6As shown, two or more moving blades 3 are evenly arranged on the outer wall of the moving blade wheel along the circumferential direction. The upper and lower positions are also provided with a limit point 14, so that each moving blade can swing freely around its pivot between the angle γo set by the upper limit point and the angle γi set by the lower limit point. The wheel disc of the moving blade wheel is provided with a shaft sleeve 12 with a keyway, and the shaft sleeve is installed with a turbine shaft 8 that extends out of the hub head on one side and can rotate synchronously with the moving blade wheel. They are all connected by a bearing 7 to ensure their smooth rotation, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com