Steam brush with rotatable heating plate

A steam brush and heating plate technology, applied in the field of steam brush, can solve the problems of small structural restrictions, high purchase cost, lack of hot surface, etc., and achieve the effects of high adaptability, reduced purchase cost, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

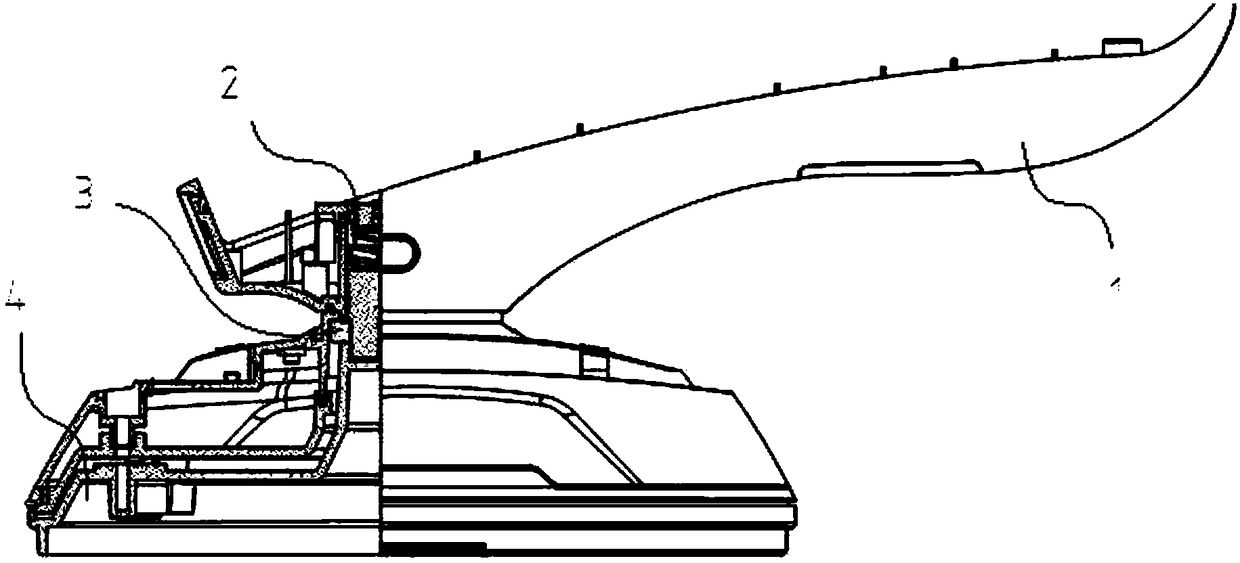

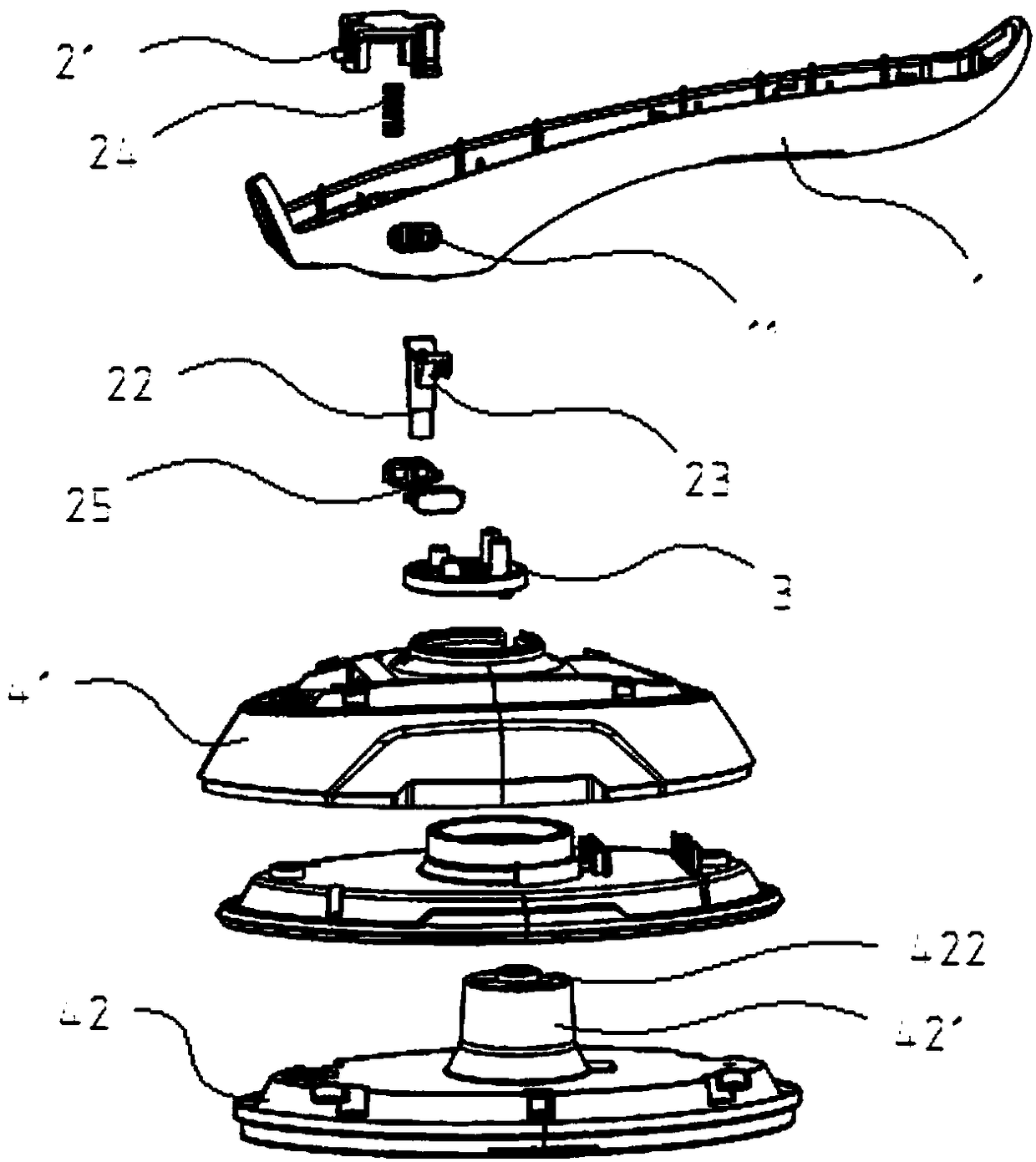

[0017] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach figure 2 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0018] figure 1 It is a structural diagram of an embodiment of a steam brush with a rotatable heating disc of the present invention; figure 2 It is an exploded view of a preferred embodiment of the present invention. Such as figure 1 and figure 2 As shown, the steam brush with a rotatable heating disc provided in this embodiment includes: a handle 1, a pressing hole 11, a rotary latch assembly 2, a latch bracket 21, a rotary latch 22, a wedge-shaped protrusion 23, a spring 24, a rotary button 25, a rotary Joint 3 , heat shield assembly 4 , water tank 41 , heat shield 42 , cylindrical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com