Heat dissipation type motor for domestic stirrer

A mixer and heat-dissipating technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that the heat cannot be dissipated quickly and in time, the heat dissipation structure is not ideal, and the heat dissipation performance is not ideal, so as to improve the heat exchange effect and maintain Work performance, the effect of accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0017] Example.

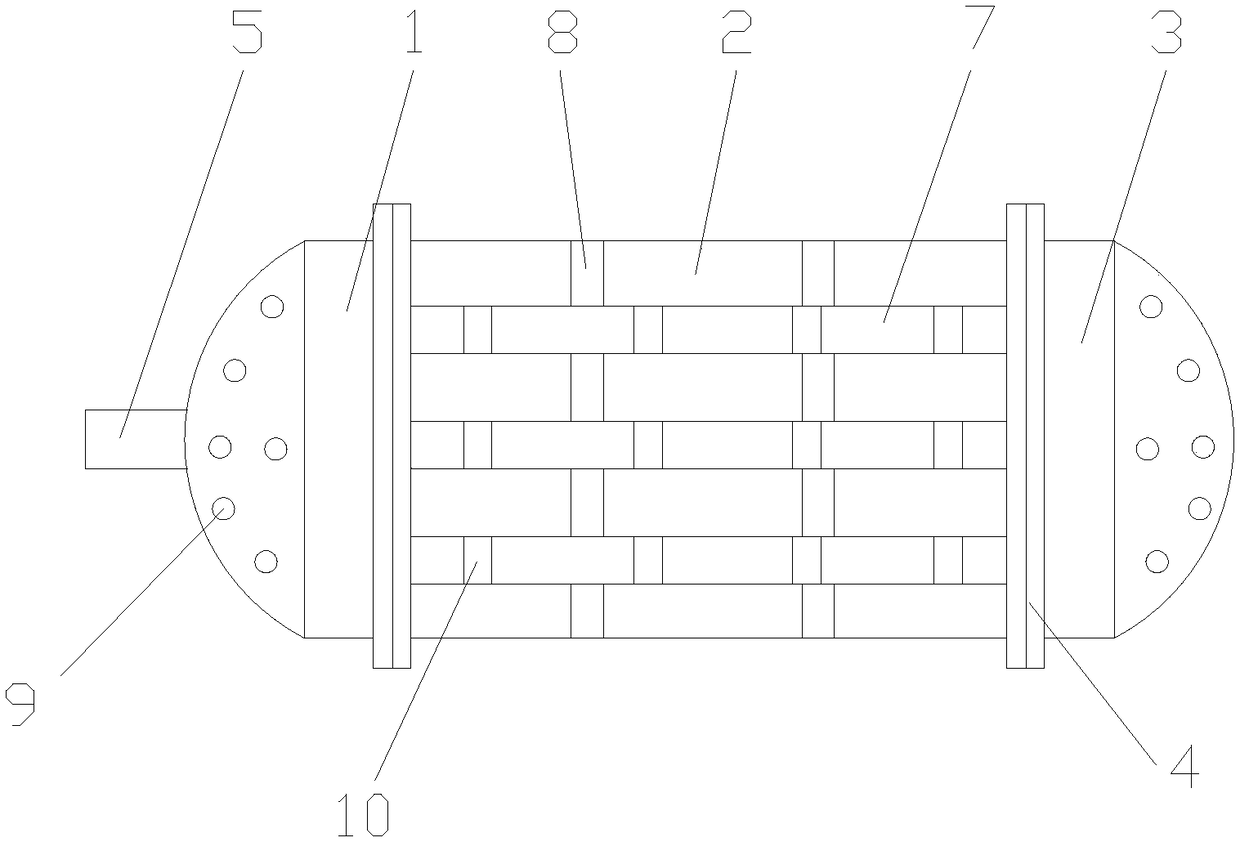

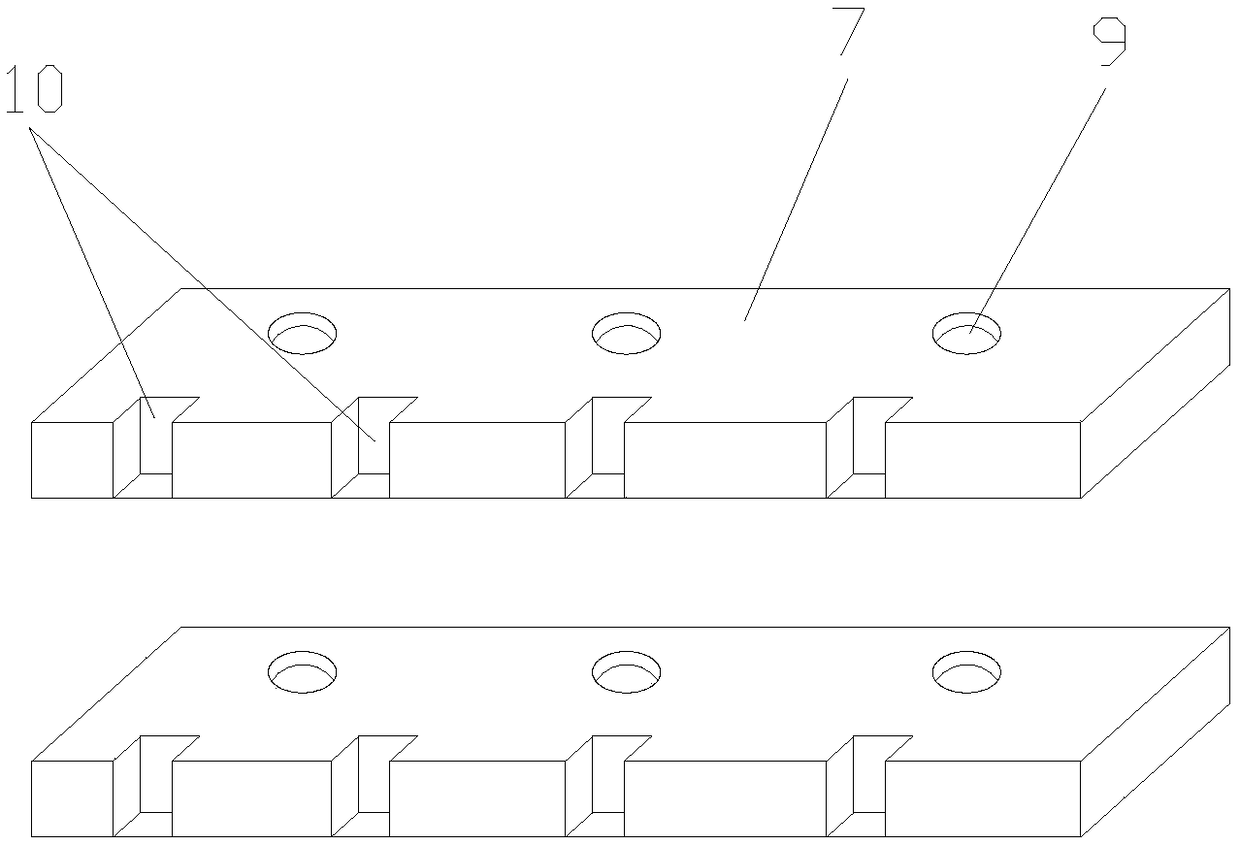

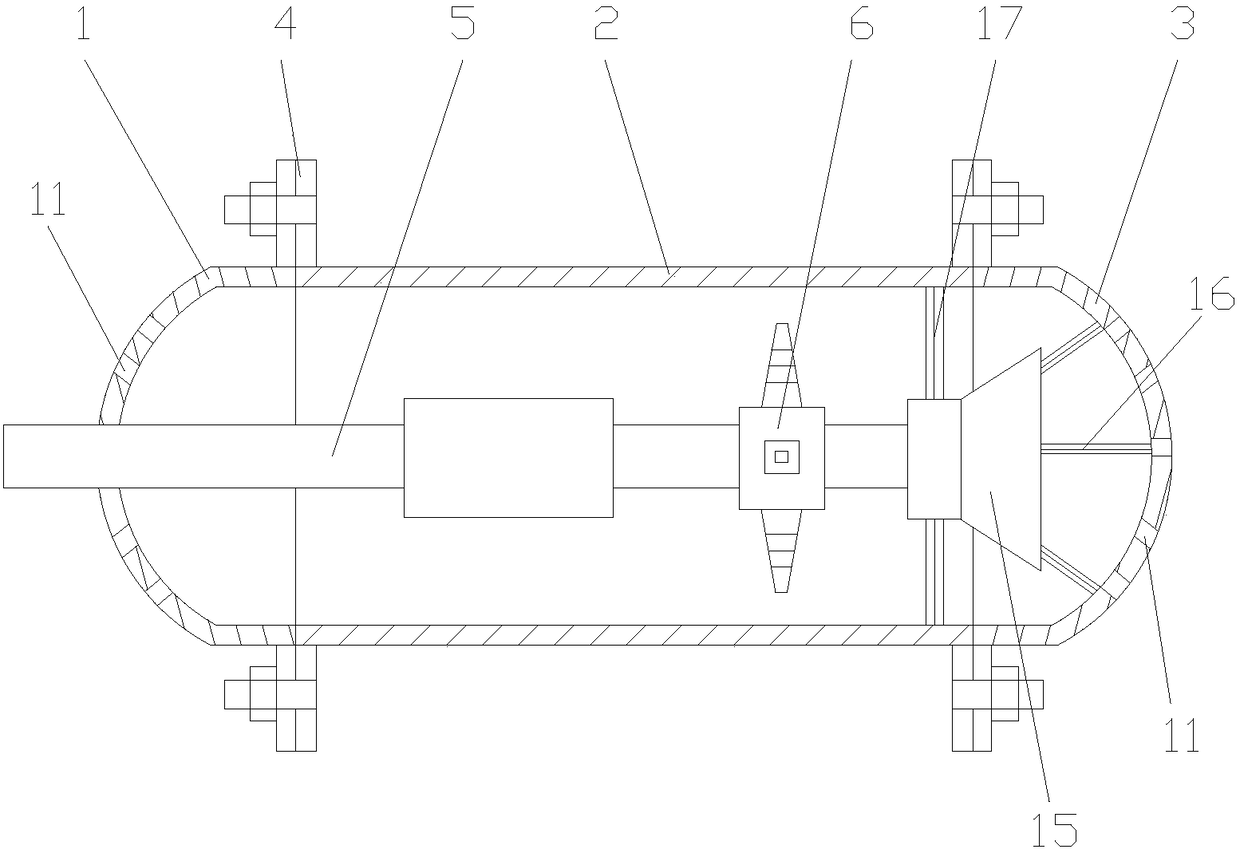

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the heat-dissipating motor for a home appliance mixer includes a front cover 1, a body 2 and a rear cover 3, and the front cover 1, the body 2 and the rear cover 3 are all connected by a flange 4, and the outer wall of the body 2 is provided with a There are some heat dissipation fins 7 and heat dissipation grooves 8, the heat dissipation grooves 8 are located between adjacent heat dissipation fins 7, and each heat dissipation fin 7 is provided with some through holes 9, and the through holes 9 on the adjacent heat dissipation fins 7 Symmetrically distributed, the outer edge of each cooling fin 7 is provided with a number of grooves 10 at intervals, the motor shaft 5 is provided inside the fuselage 2, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com