Carbon fiber vernier caliper

A vernier caliper and carbon fiber technology, which is applied in the field of surveying and mapping tools, can solve the problems of unsuitable use, high precision requirements, and high cost, and achieve the effects of good corrosion resistance, good electromagnetic shielding, and small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

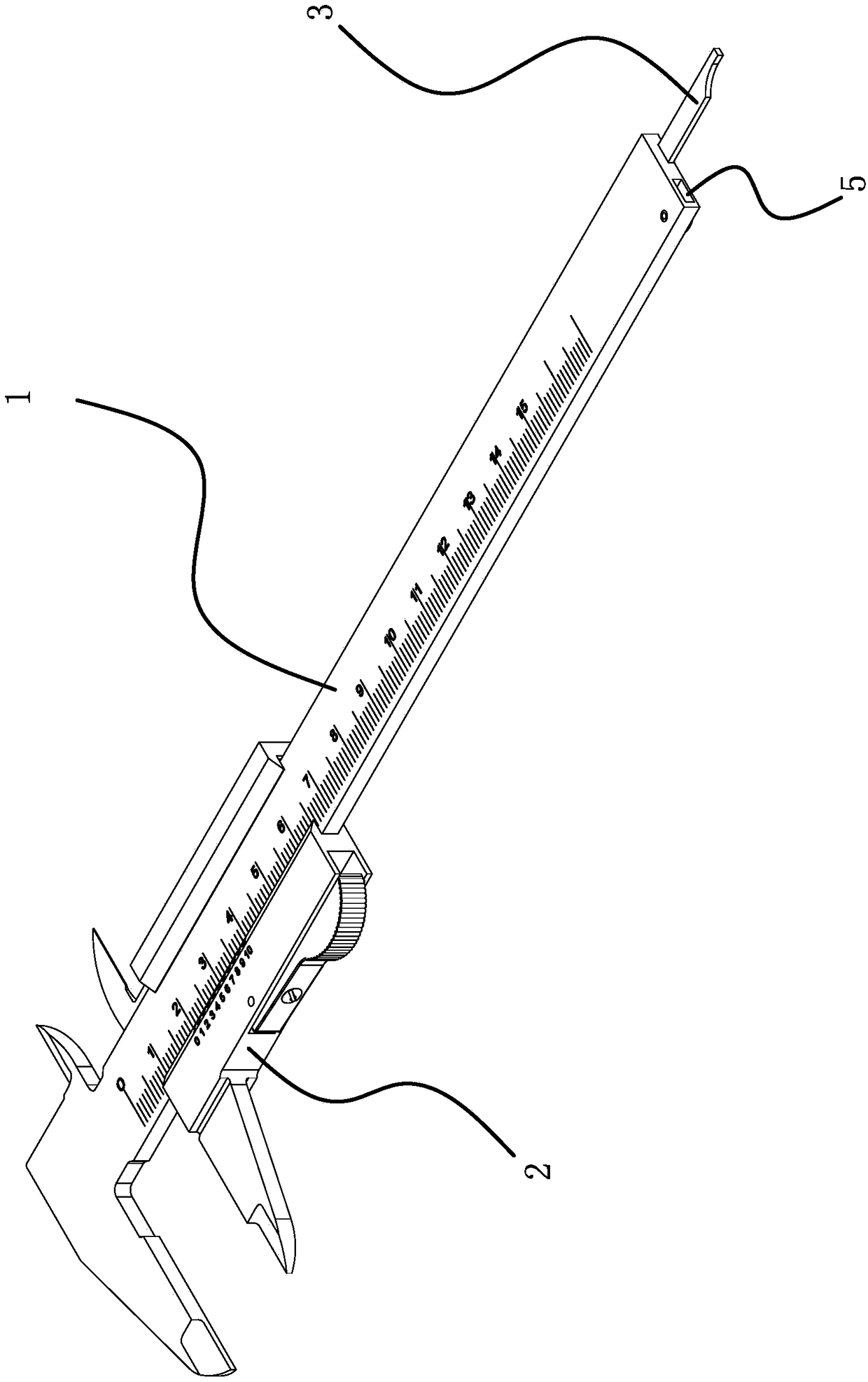

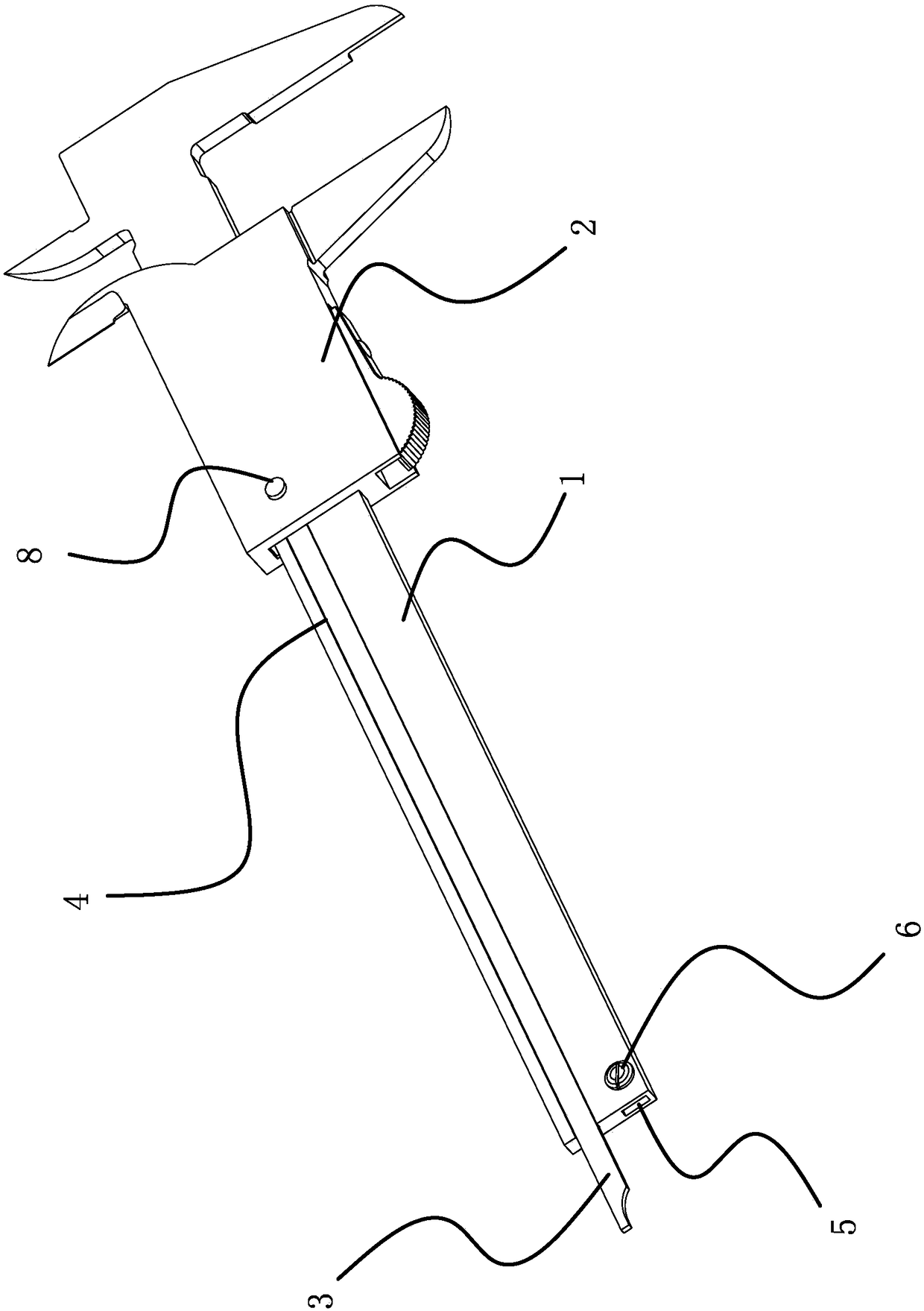

[0024] Such as figure 1 , 2 , 3, the carbon fiber vernier caliper comprises a main ruler 1, a vernier ruler 2 and a sounding ruler 3, and the main ruler 1, the vernier ruler 2 and the sounding ruler 3 are all made of carbon fiber materials. The vernier ruler 2 is set on the main ruler 1 and can slide along the main ruler 1. The back of the main ruler 1 is provided with a square chute 4 for embedding the sounding ruler 3, and the vernier caliper is detachably connected with the sounding ruler 3.

[0025] The main ruler 1 has a storage cavity 5, the opening of the storage cavity 5 is located at the tail end of the main ruler 1, the sounding ruler 3 can be inserted into the storage cavity 5, the depth of the storage cavity 5 is greater than the length of the sounding ruler 3, and the storage Cavity 5 is rectangular parallelepiped, is threaded with the bolt 6 that seals off storage chamber 5 openings on main chi 1 tail end.

[0026] The front end of the sounding gauge 3 has a co...

Embodiment 2

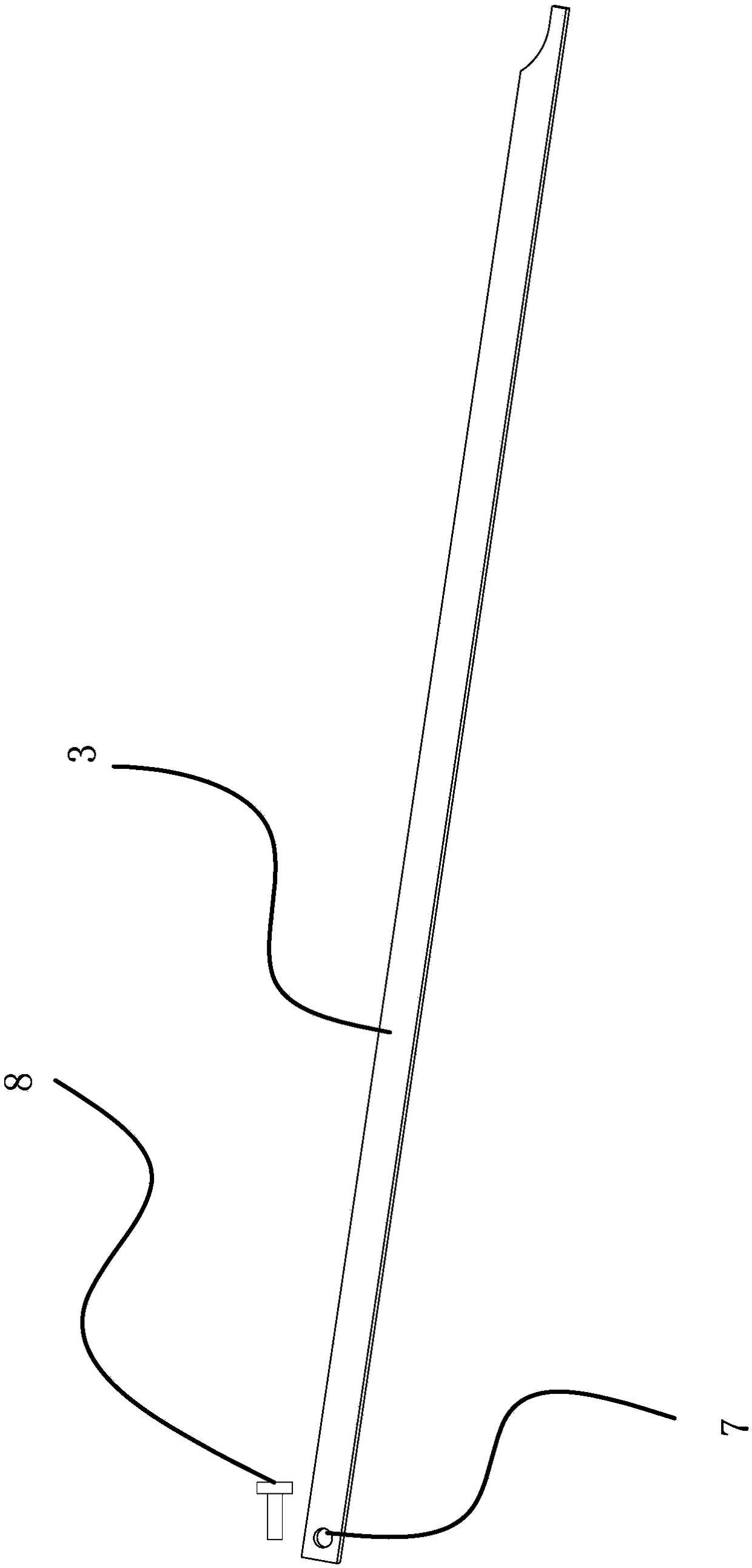

[0028] Such as Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is that the connection mode between the sounding scale 3 and the vernier scale 2 is different. The front end of the sounding ruler 3 in this embodiment has an upwardly protruding block 9, and the end surface of the vernier 2 is connected with a bar-shaped auxiliary block 10 through a screw 11, and the inner side of the bar-shaped auxiliary block 10 is provided with a hole for the locking block 9 to snap into. Square notch 12. During dismounting, the screw 11 is unscrewed, the bar-shaped auxiliary block 10 is opened, the block 9 of the sounding gauge 3 can be disengaged from the square notch 12, and then the sounding gauge 3 is inserted in the storage cavity 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com