Mop provided with self-water-squeezing foamed cotton head

A technology of foaming cotton and self-squeezing water, which is applied to cleaning carpets, floors, and cleaning equipment. It can solve the problems of many consumables, large contact area between the water squeezer and the cotton head, and poor adaptability to mopping the floor. Comfortable and reasonable, better squeezing effect, labor-saving effect of squeezing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

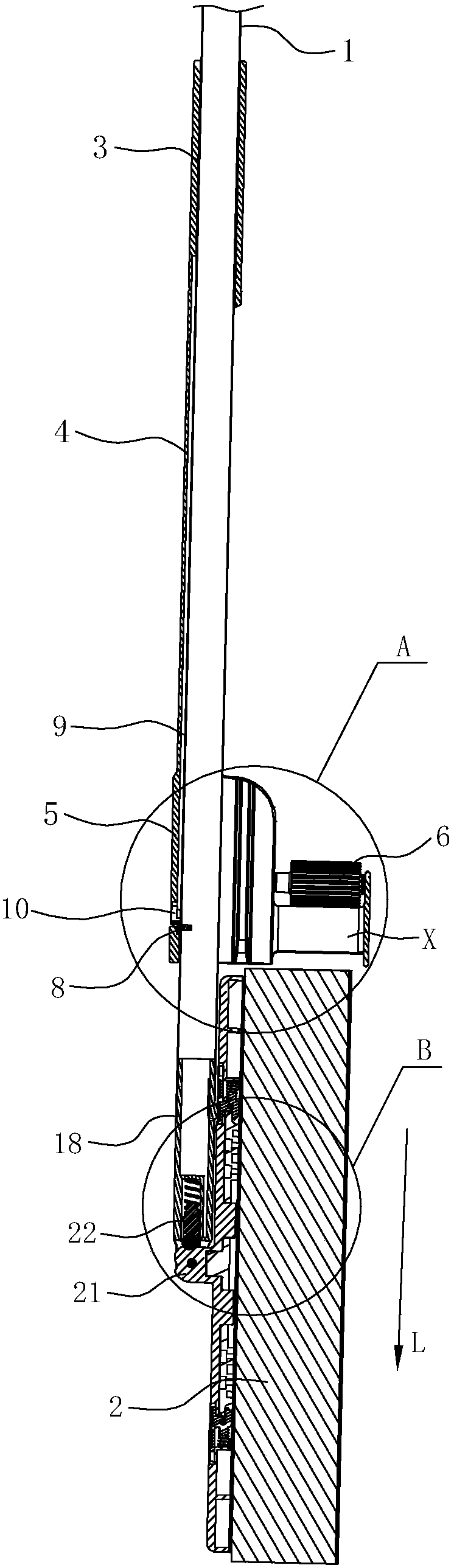

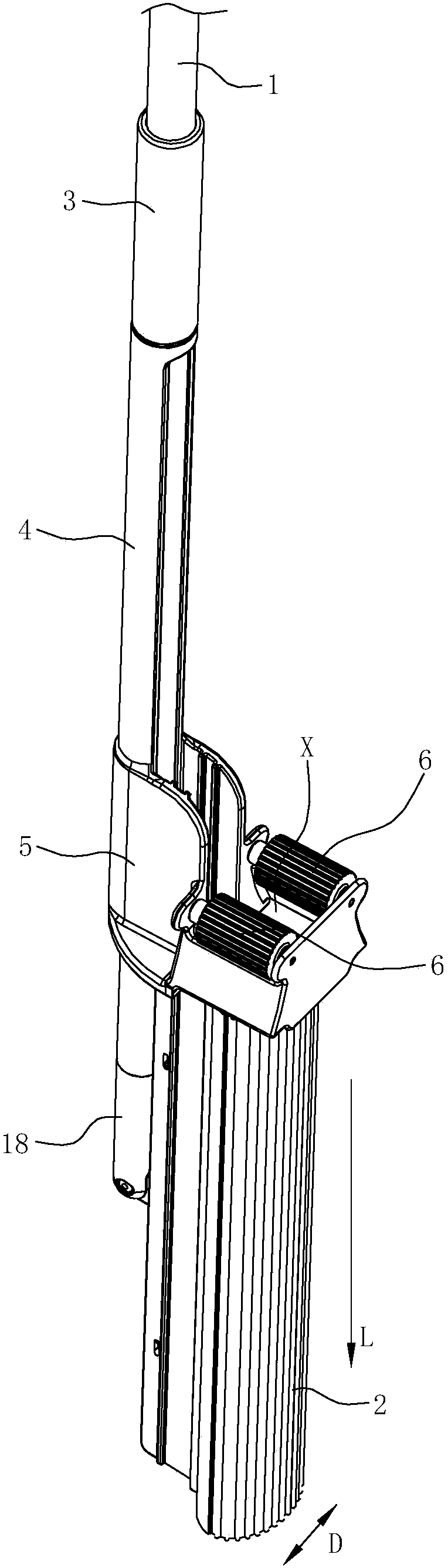

[0047] like Figure 1~5 Shown is the first embodiment of the present invention.

[0048] A self-squeezing mop with foamed cotton heads, comprising a mop rod 1, a foamed cotton head 2, the foamed cotton head 2 is generally composed of foamed cotton and cotton clips, and the foamed cotton can be collodion, sponge and the like .

[0049] The foamed cotton head 2 is rotatably connected to the lower end of the mop rod 1. The mop rod 1 is provided with an extruding device capable of sliding relative to the mop rod. According to the water squeezing device, when squeezing water, the water squeezing device slides up and down along the length direction L of the foamed cotton head 2 and squeezes the left and right sides of the foamed cotton head 2 to realize water squeezing. The foamed cotton head 2 breaks away from the water squeezing device complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com