Detection method for curing degree of glue

A glue curing and detection method technology, applied in the direction of measuring devices, strength characteristics, test material hardness, etc., can solve the problems of glue encroaching on the chip, bad, and not conducive to the prevention of quality hidden dangers, etc., to achieve low risk of misjudgment and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The utility model will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0032] The invention provides a method for detecting the curing degree of glue,

[0033] Including providing A-type Shore hardness tester, semi-cured glue samples;

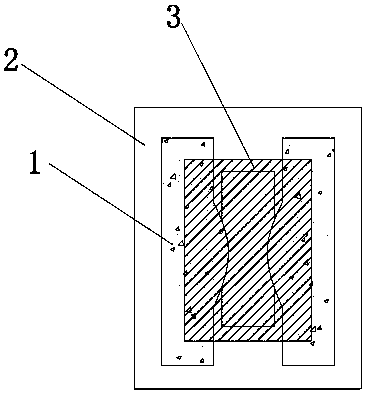

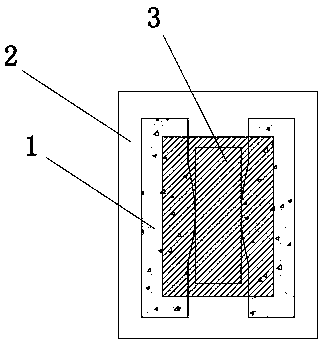

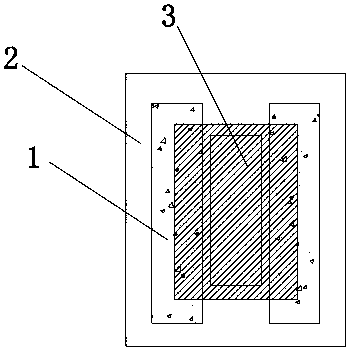

[0034] The semi-cured glue sample includes glue 1, chip 2, and substrate 3; glue 1 is between chip 2 and substrate 3, and connects both ends of chip 2 to substrate 3;

[0035] Step 1, place the semi-cured glue sample on a solid plane;

[0036] Step 2, A-type Shore hardness tester indents to the edge;

[0037] Step 3, press the presser foot in parallel on the surface of the semi-cured glue sample;

[0038] Step 4, press the needle vertically into the sample;

[0039] Step 5, take a reading immediately after pressing down;

[0040] Step 6, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com