Ground marking line drawing instrument for standardized factory

A technology for landmarks and workshops, which is applied in the direction of construction, building structure, and building materials processing. It can solve the problems of waste of resources, harmful paint, and inconvenient cleaning. It can achieve neat and beautiful edges of paint lines, reduce labor intensity, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

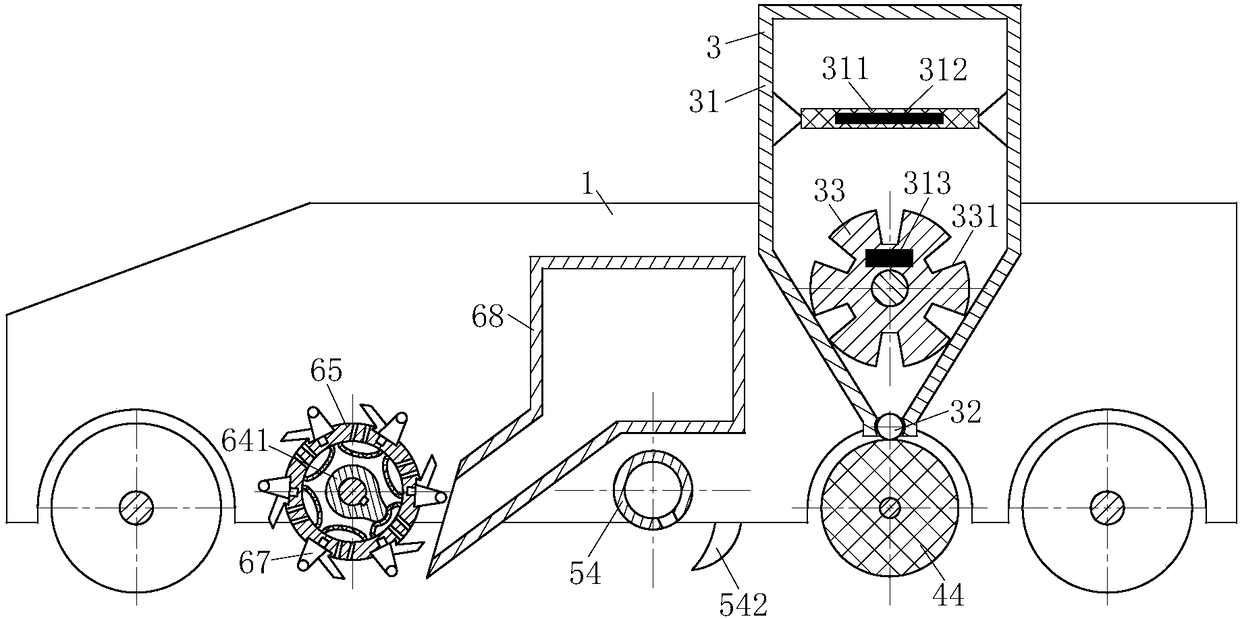

[0033] As an embodiment of the present invention, the cutter assembly 67 includes a scraper 671 and a grinding sheet 672; the scraper 671 is arranged along the tangential direction of the cleaning roller 65; one side of the scraper 671 is fixedly connected to the grinding sheet 672, and the cleaning roller 65 While rotating and scraping off the old paint, the ground is polished by using the grinding disc 672 to improve the flatness of the ground, so that the subsequent paint line is smooth and beautiful.

[0034] As an embodiment of the present invention, the inside of the cleaning roller 65 is provided with a cavity; one side of the cavity is fixed with a blowing bag 651; the outer periphery of the fixed shaft 64 is provided with a cam 641 connected by a key; The rotation of the cleaning roller 65 can make the cam 641 squeeze the blowing bag 651 intermittently; The air flow can clean the scraper 671 in time to prevent the surface of the scraper 671 from adhering to debris and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com