A kind of concrete heat preservation and humidity control block

A concrete, temperature and humidity regulation technology, applied in the field of building materials, can solve the problems of no temperature regulation effect, difficult to regulate temperature and humidity, and difficult to play the role of temperature and humidity regulation, etc., to achieve good heat insulation effect, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

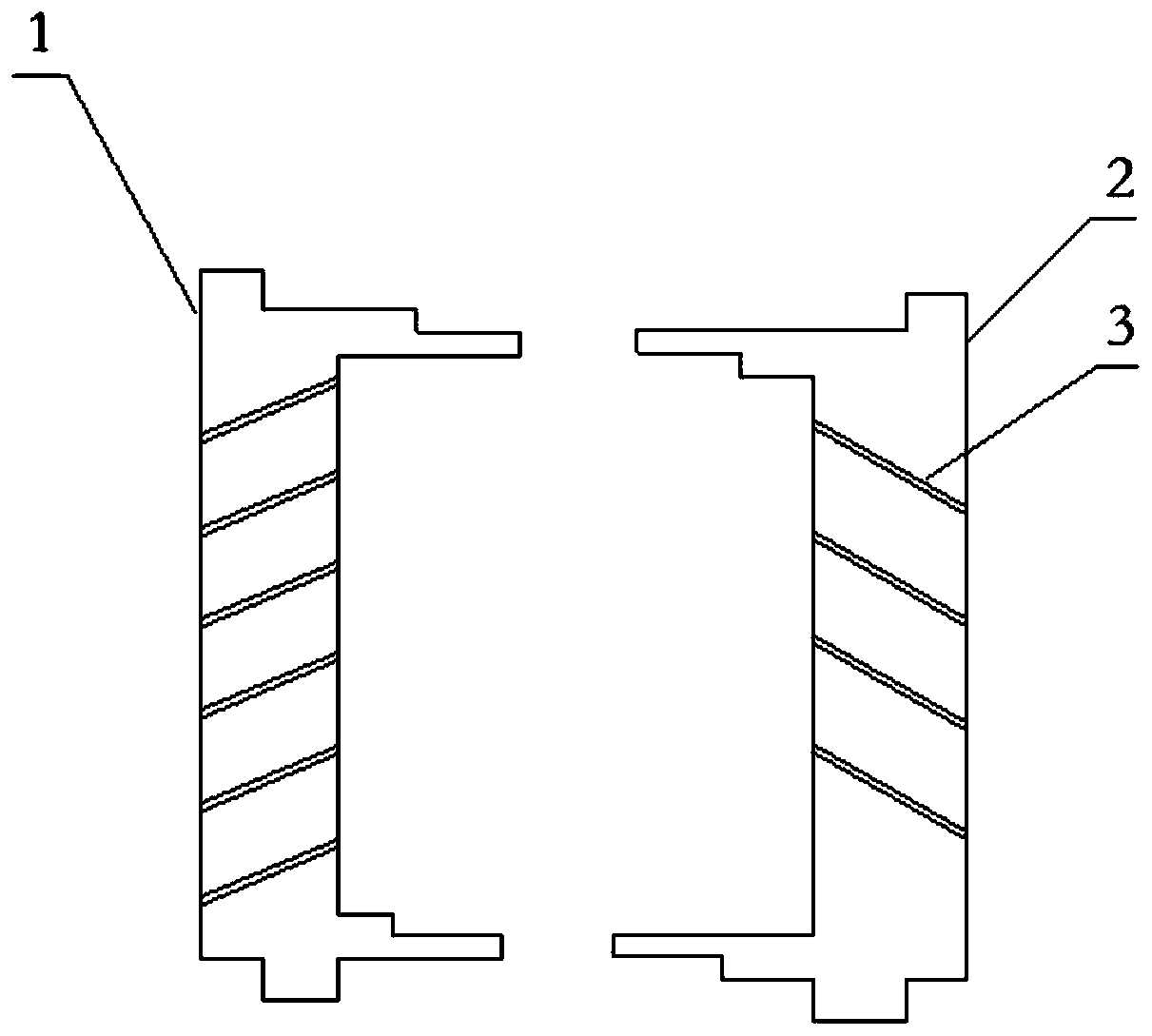

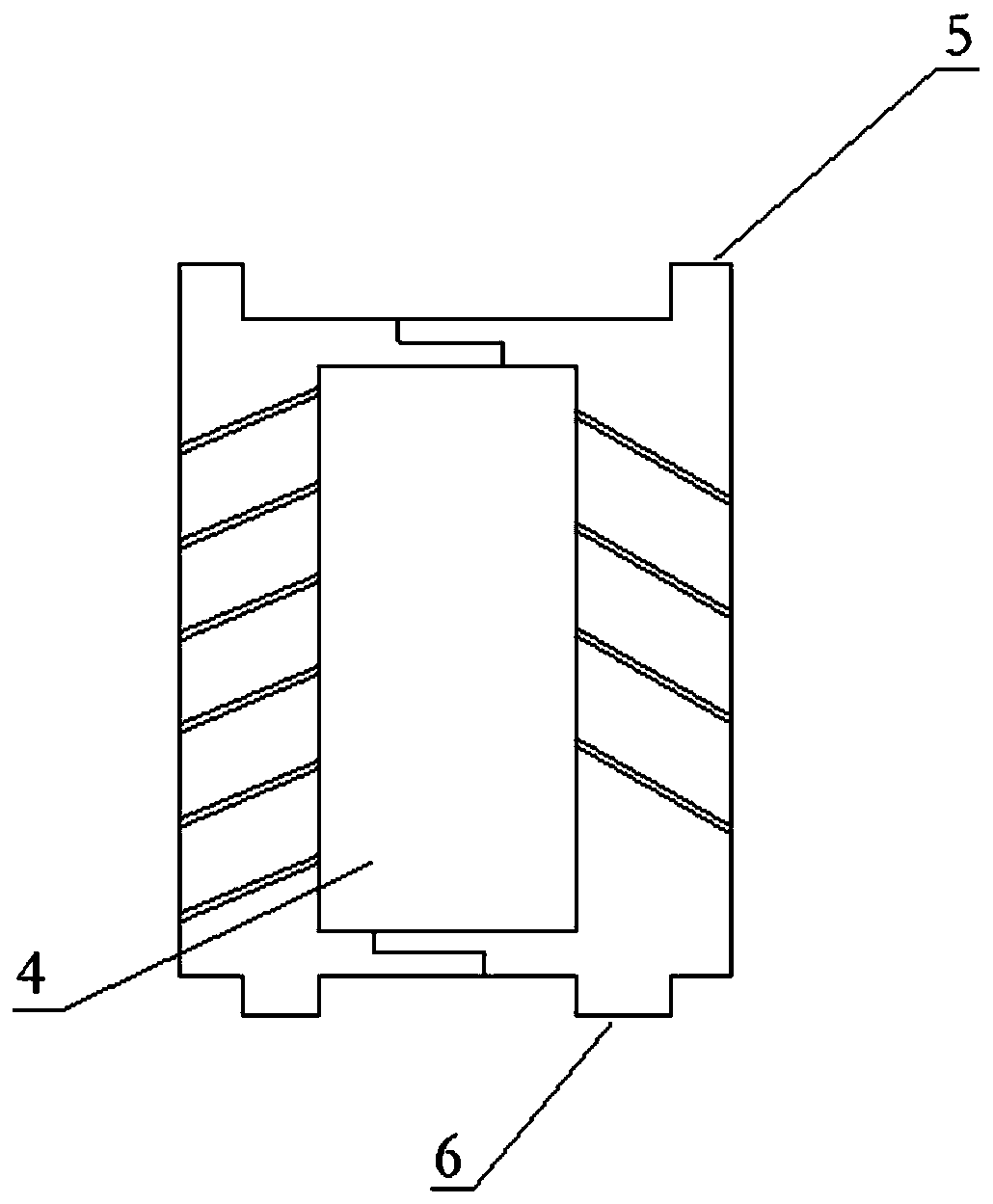

[0027] Such as figure 1 As shown, it is a schematic diagram of the concrete thermal insulation and humidity control block provided in this embodiment, and the block includes a first assembly unit 1 and a second assembly unit 2; figure 2 As shown, the first assembly unit 1 and the second assembly unit 2 are assembled into a block with closed surroundings and a cavity 4 inside through the joint opening; both the first assembly unit 1 and the second assembly unit 2 are provided with through air holes 3. The top of the block is provided with a first boss 5, and the bottom is provided with a second boss 6, and the blocks are assembled together through the first boss 5 and the second boss 6; the assembly of the blocks can be realized.

[0028] In the above concrete thermal insulation and humidity control block, the air hole 3 can be set as a slanted through hole that is high on the inside and low on the outside. This setting can not only realize the function of self-breathing to b...

Embodiment 2

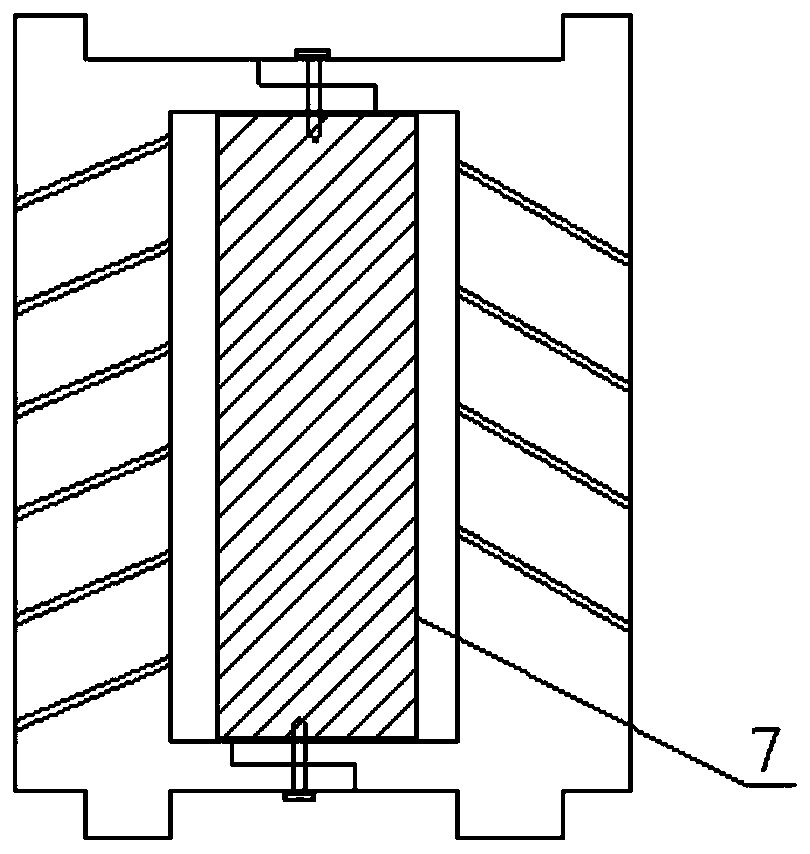

[0030] Such as image 3 As shown, it is a schematic diagram of the concrete thermal insulation and humidity control block provided in this embodiment, wherein the temperature and humidity control material 7 is arranged in the cavity 4, and there is a gap between the temperature and humidity control material 7 and the inner wall of the cavity 4, and the two blocks After mutual bonding, a hollow bonding cavity 8 is formed in the region where the first boss 5 and the second boss 6 are bonded together.

[0031] The above temperature and humidity control material 7 is prepared by the following method:

[0032] Step 1, mix 20-30 parts by weight of gypsum powder, 3-5 parts of sodium polymethacrylate, 2-5 parts of polyester fiber and 1-3 parts of hypromellose, then add 30-40 parts of water part, stirred for 20-30 minutes to obtain mixture 1;

[0033] Step 2, add 0.5-1 parts of fatty alcohol polyoxyethylene ether sodium sulfate in parts by weight to 8-10 parts of water, stir and diss...

Embodiment 3

[0038] Using the technical solution in Example 2, the temperature and humidity control material 7 is prepared by the following method:

[0039] Step 1: Mix 20 parts by weight of gypsum powder, 3 parts of sodium polymethacrylate, 2 parts of polyester fiber and 1 part of hypromellose, then add 30 parts of water and stir for 20 minutes to obtain mixture 1;

[0040] Step 2, adding 0.5 parts of fatty alcohol polyoxyethylene ether sodium sulfate in parts by weight to 8 parts of water, stirring and dissolving it, adding it to mixture 1, adding 3 parts of bentonite, mixing evenly and placing it in a mold. drying at 70°C to obtain a temperature-adjusting and humidity-adjusting material 1;

[0041] Step 3, bonding hollow fibers on one surface of the temperature and humidity control material with an adhesive to form a temperature and humidity control material with a hollow fiber layer adhered to the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com