A multi-point adaptive jacking device for steel box girder

A multi-point self-adaptive, jacking device technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of affecting work efficiency, wasting time, and low requirements, so as to improve work efficiency, facilitate use, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

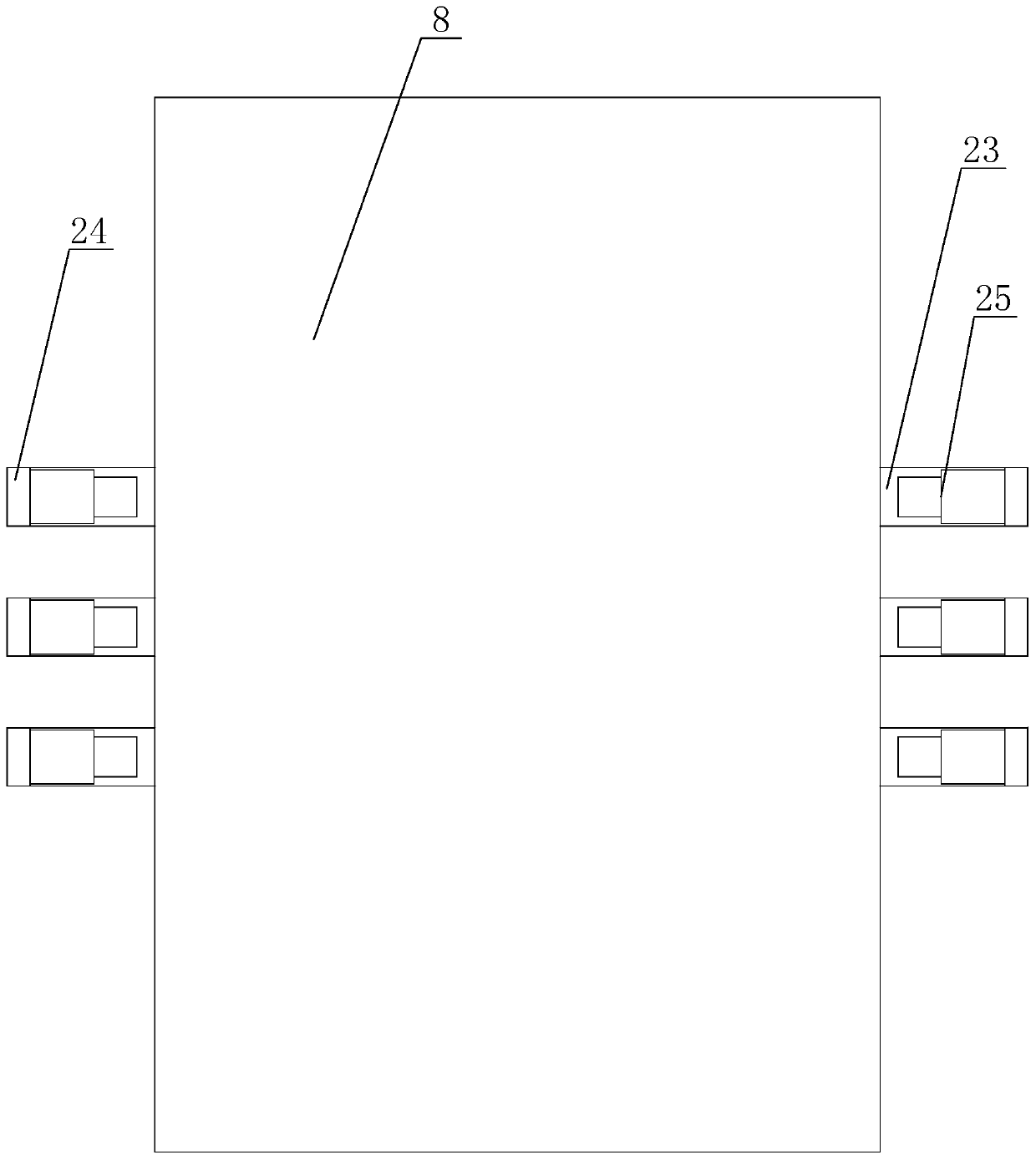

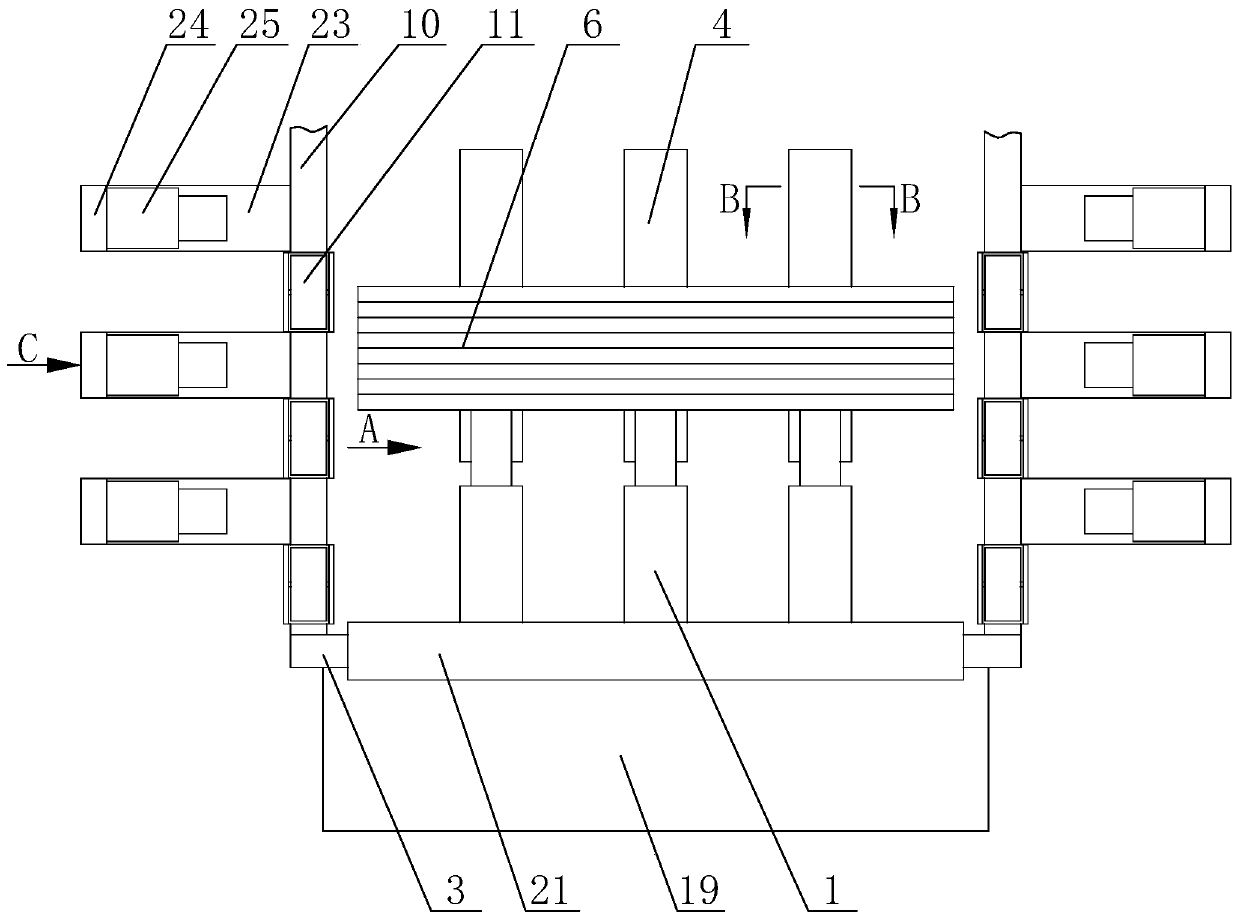

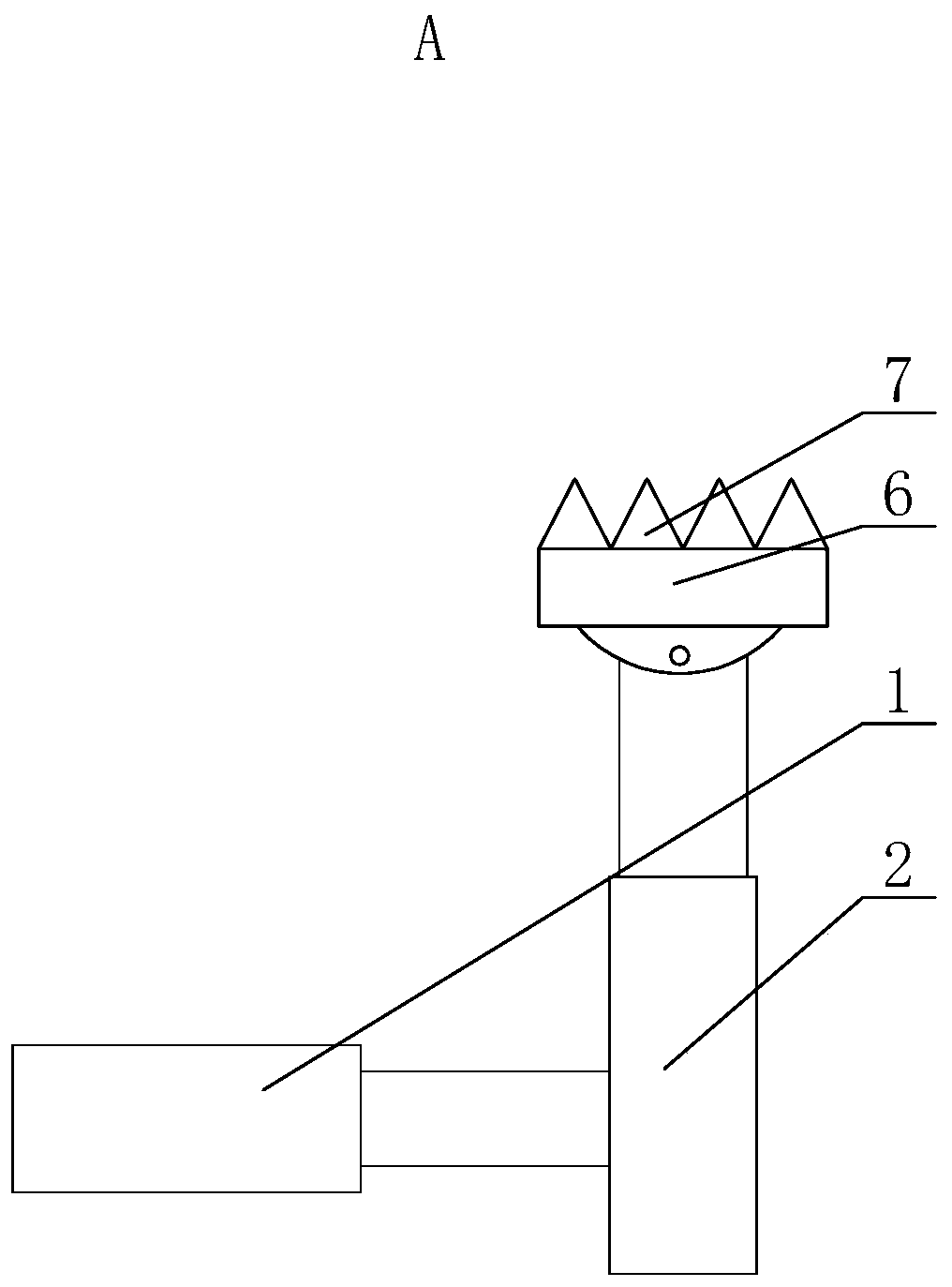

[0034] A multi-point self-adaptive jacking device for a steel box girder, comprising a horizontal jack 1 and a vertical jack 2, one end of the horizontal jack 1 is fixedly connected to the vertical jack 2, and the other end of the horizontal jack 1 is fixed Installed on the riser 3, the rear portion of the riser 3 is provided with the top of the first support plate 19 connected obliquely, and the bottom end of the first support plate 19 is fixedly connected with one end of the bottom plate 20, The other end of the base plate 20 is fixedly connected to the bottom of the riser 3, the top of the riser 3 is provided with a buffer plate 21, the height of the buffer plate 21 is lower than that of the auxiliary pulley 11, and the buffer plate 21 is lower than the height of the auxiliary pulley 11. A third shock absorber 22 is arranged between the plate 21 and the top of the vertical plate 3, the bottom of the vertical jack 2 is located in the chute 4, the bottom of the vertical jack 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com