Energy-saving condensing piece of compact spinning device

A compact spinning and agglomeration tank technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of large opening area, high energy consumption, large air flow, etc., to reduce air flow and ensure agglomeration effect. , the effect of reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

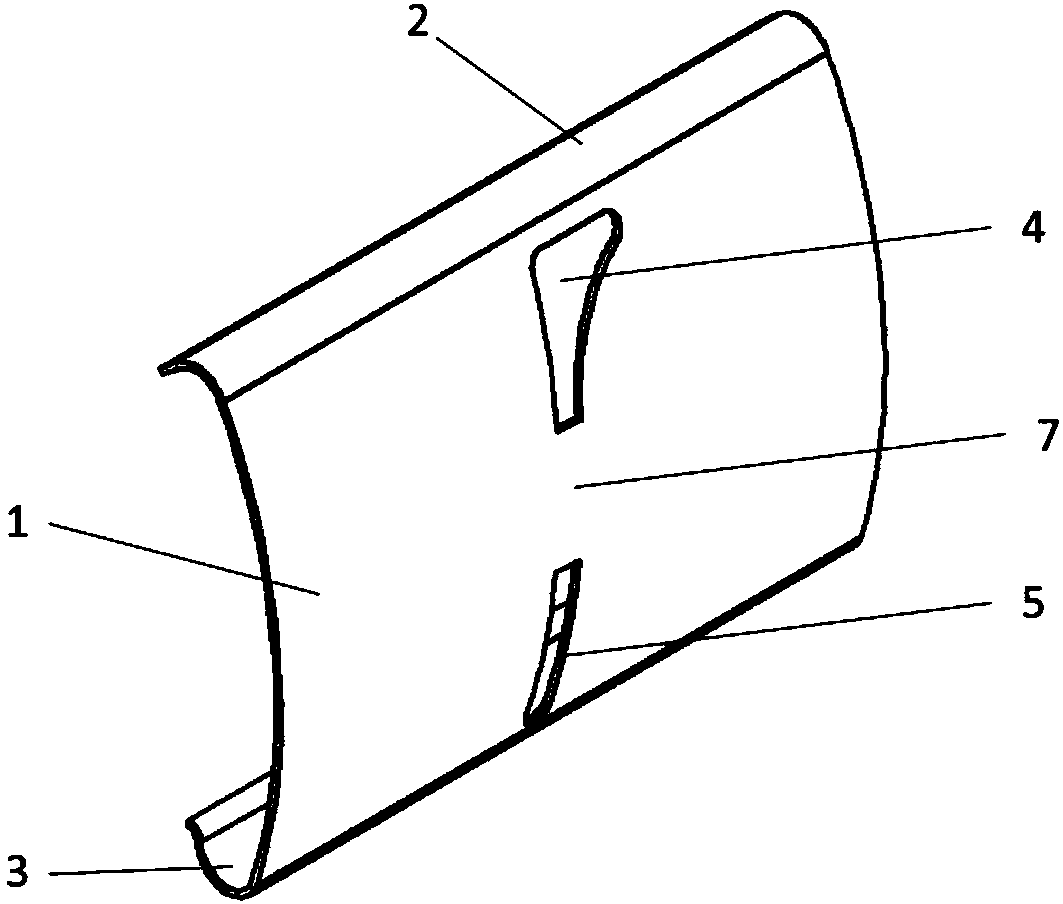

[0019] Such as image 3 As shown, an energy-saving accumulating sheet for a compact spinning device includes an accumulating sheet main body 1, an upper curved arc 2, and a lower curved arc 3. An upper accumulating groove 4 is opened on the upper part of the accumulating sheet main body 1, and a lower accumulating groove 5 is opened on the lower part of the accumulating sheet main body. , the transition zone 7 is in the middle of the upper collecting groove and the lower collecting groove. Wherein, both the upper collecting groove and the lower collecting groove are single grooves, and the notch center lines of the upper collecting groove and the lower collecting groove coincide, and the main body of the collecting sheet is made of stainless steel.

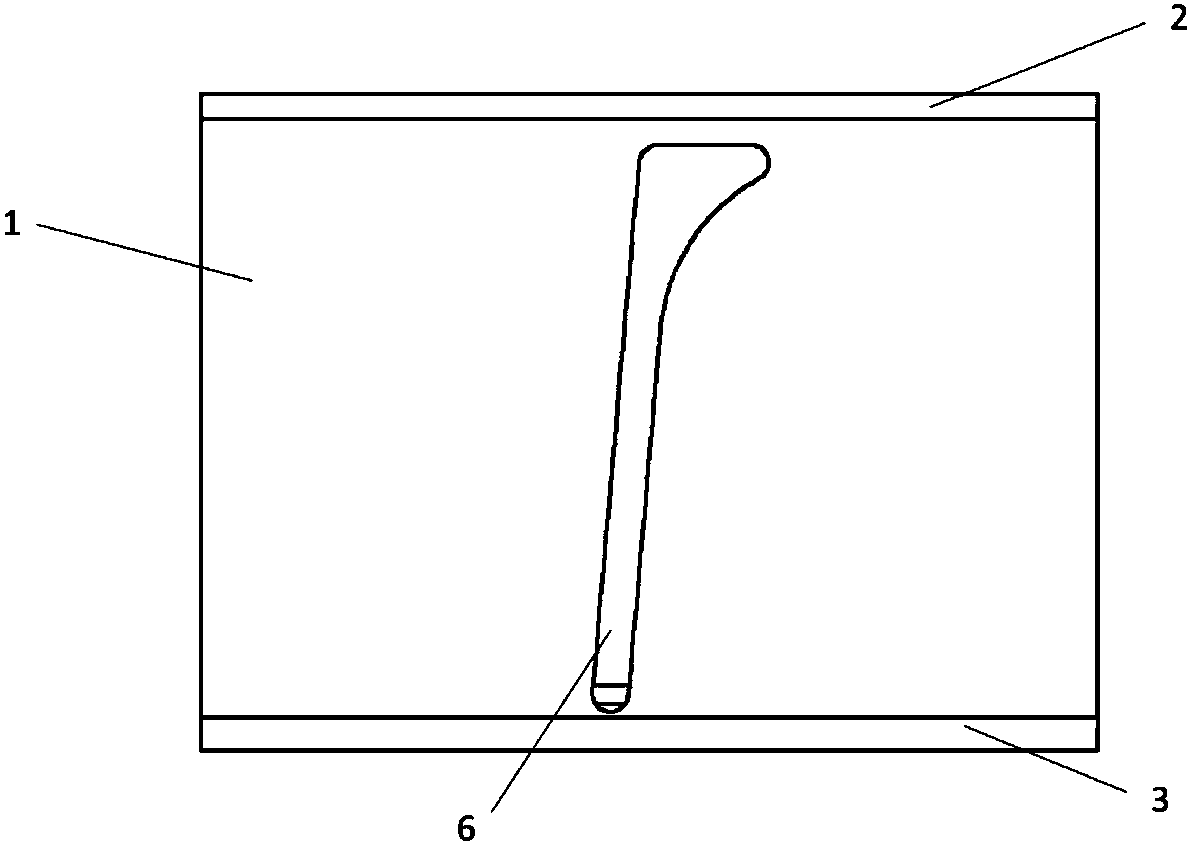

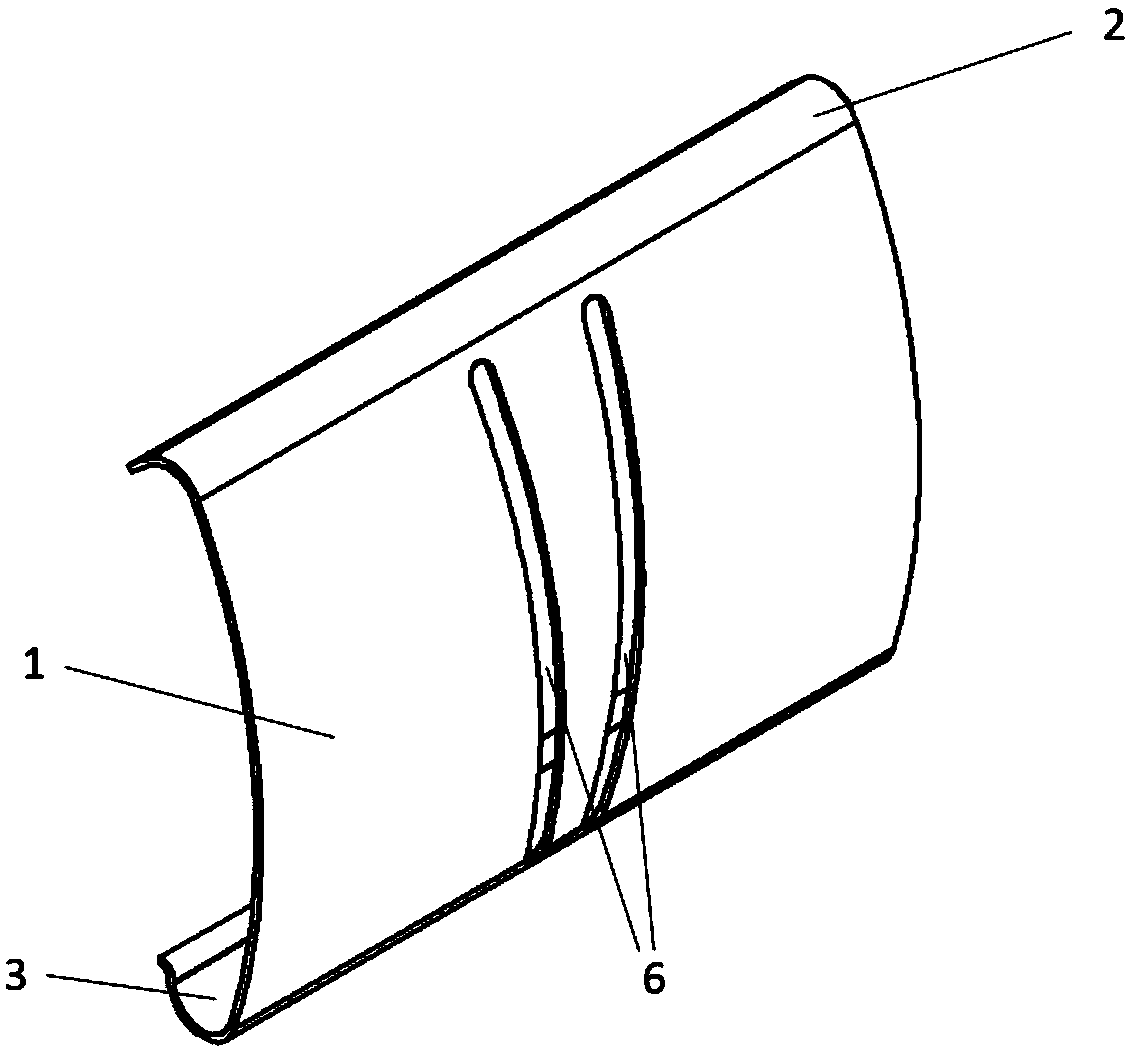

[0020] figure 1 Shown is a prior art single groove packing piece. Will image 3 The energy-saving compacting sheet of the compact spinning device shown is according to Figure 5 The way shown is assembled on the special-shaped...

Embodiment 2

[0022] Such as Figure 4 As shown, an energy-saving accumulating sheet for a compact spinning device includes an accumulating sheet main body 1, an upper curved arc 2, and a lower curved arc 3. An upper accumulating groove 4 is opened on the upper part of the accumulating sheet main body 1, and a lower accumulating groove 5 is opened on the lower part of the accumulating sheet main body. , the transition zone 7 is in the middle of the upper collecting groove and the lower collecting groove. Wherein, both the upper collecting groove and the lower collecting groove are double grooves, and the centerlines of the notches corresponding to the upper collecting groove and the lower collecting groove coincide, and the main body of the collecting sheet is made of elastic metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com