Multistage profiling device for rubber tape, and rubber part winding unit

A technology of rubber parts and rubber strips, which is applied in the field of rubber parts winding units, can solve the problems that rubber strips cannot reach the thickness or width, reduce the winding efficiency of rubber parts, and the production efficiency of rubber strips is low, so as to improve the winding efficiency and winding The effect of quality, cost saving and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

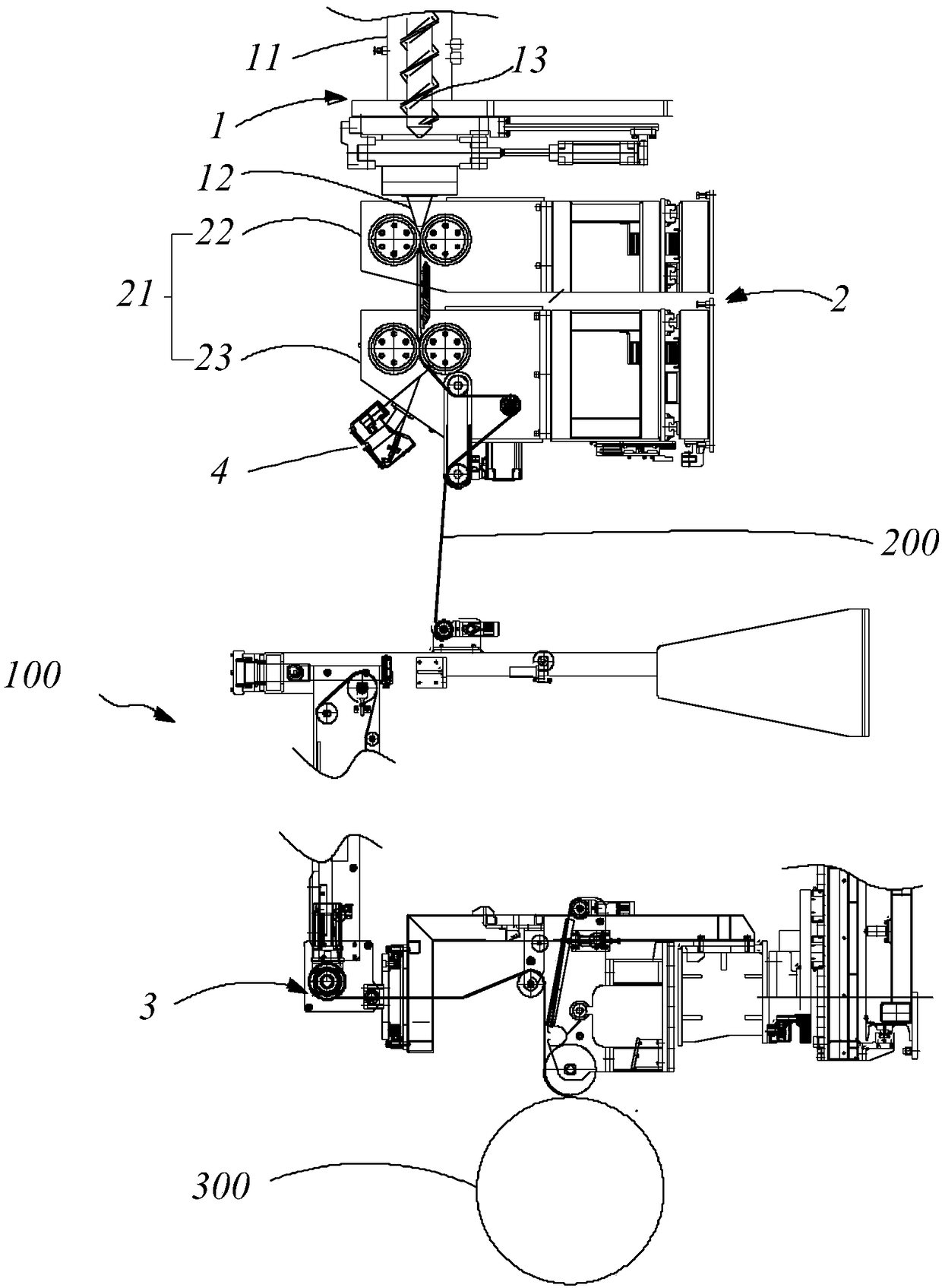

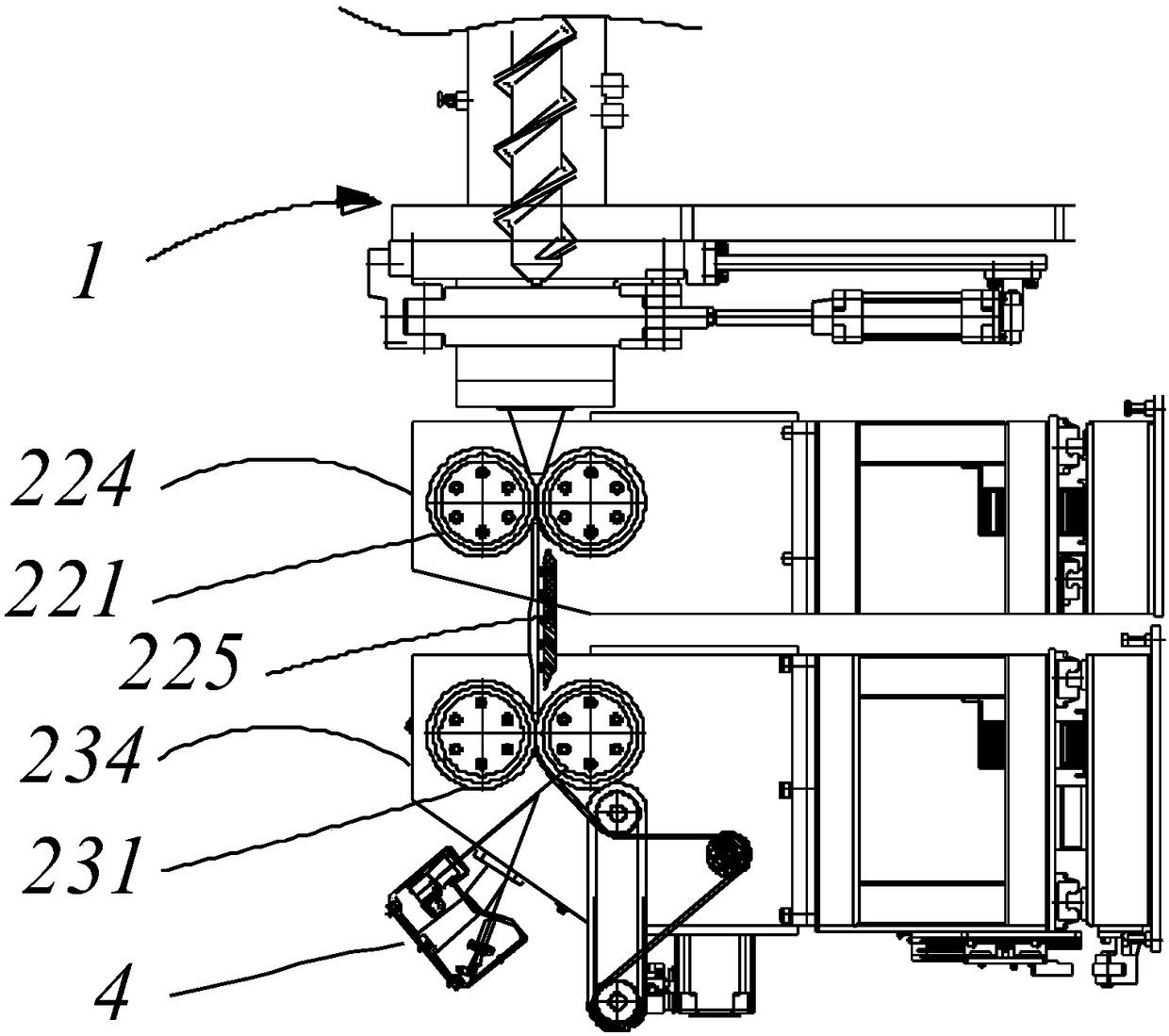

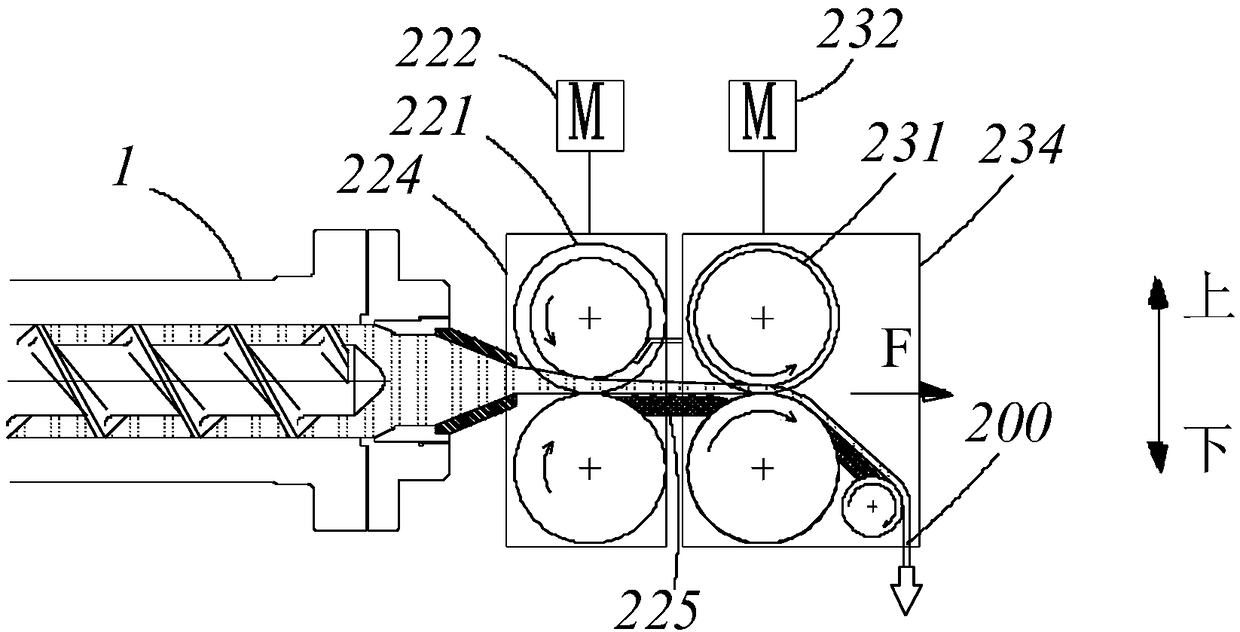

[0026] See Figure 1~Figure 4 , the present invention provides a rubber component winding unit 100, comprising an extruder device 1, a rubber strip multi-stage pressing device 2, a winding host 3 for winding the pressed rubber strip, and a rubber strip multi-stage press The detection device 4 and the control system at the extrusion end of the type device 2. Wherein, the extruder device 1 includes an extruder body 11, a material inlet (unlabeled) and a discharge port 12 arranged on the extruder body 11, a screw 13 arranged inside the extruder body 11, The material receiving port receives the rubber compound, and through the reprocessing inside the extruder body 11, the processed rubber compound is extruded from the discharge port 12 through the screw 13, and the rubber enters the rubber strip multi-stage pressing device 2 , and form a continuous rubber strip 200 after being pressed by the strip multi-stage profiling device 2 , and finally wind the rubber strip 200 onto the rub...

Embodiment 2

[0038] Example 2: see Image 6 , the difference from Embodiment 1 is only the arrangement of the two profiling rollers 231 in the profiling roller assembly 23, the profiling roller assembly 22 and the profiling roller assembly 23 in Embodiment 1 are horizontally arranged side by side, this embodiment The profiling roller assembly 22 and the profiling roller assembly 23 are arranged up and down.

[0039] It can be understood that the number of the profiling roller assemblies 23 can also be multiple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com