Slurry mixer for battery electrode

A technology for battery electrodes and mixers, which is applied in the direction of mixer accessories, electrode manufacturing, and mixers with rotating stirring devices, etc. It can solve the problem of difficult to set the motor rotation speed at high speed, unable to greatly increase production, and unable to maintain the best state, etc. problem, achieve the effects of shortening the stirring time, simple structure, and preventing scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

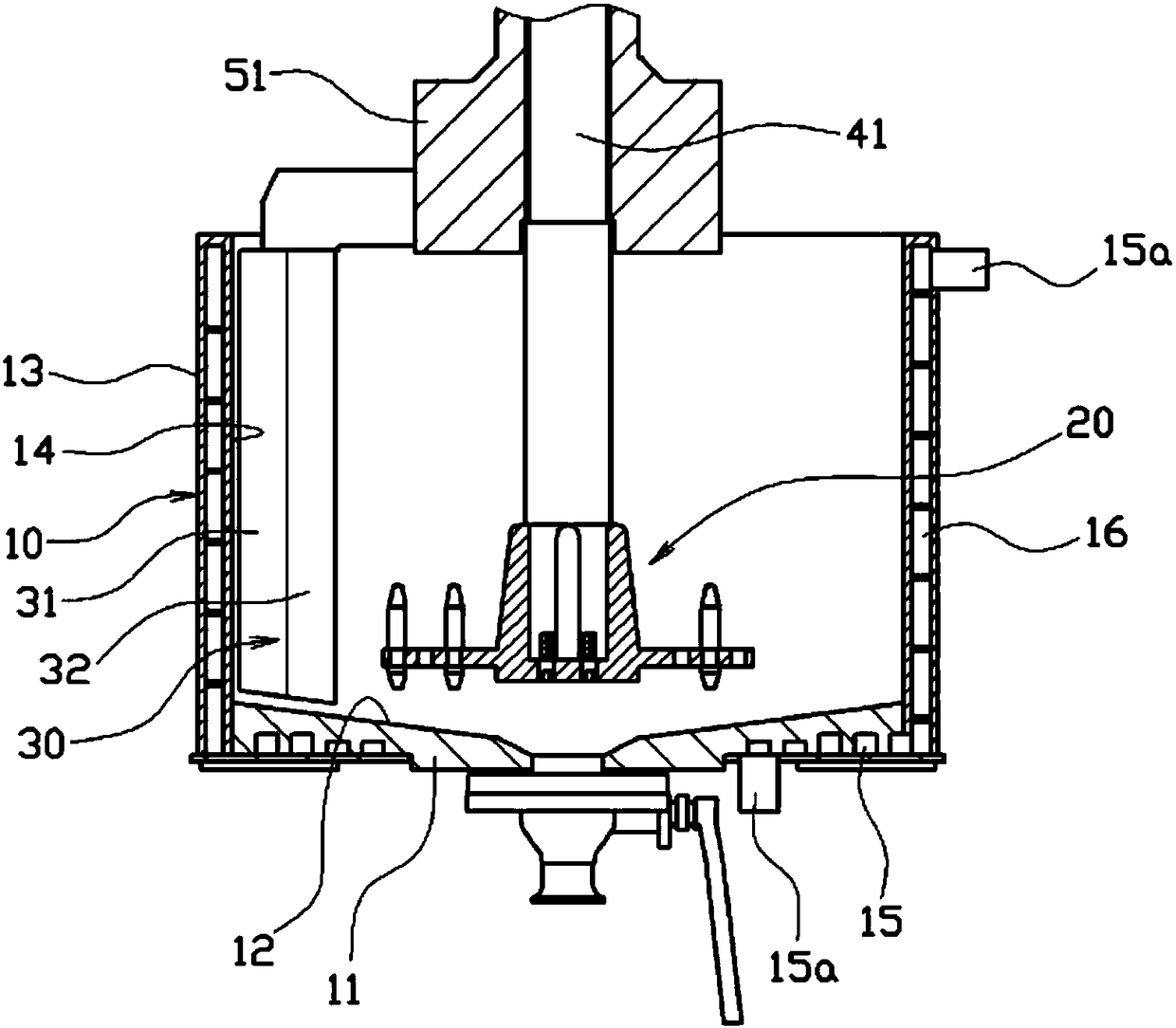

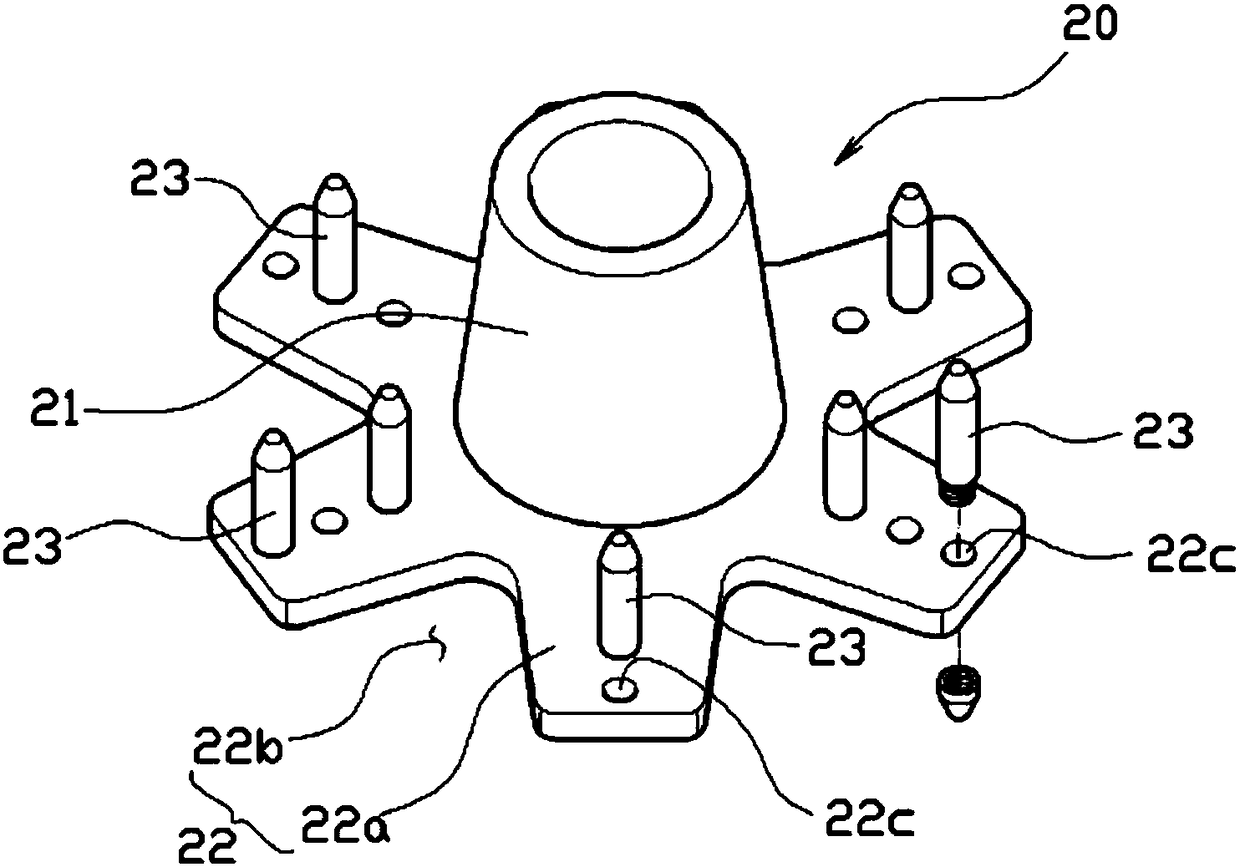

[0046] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

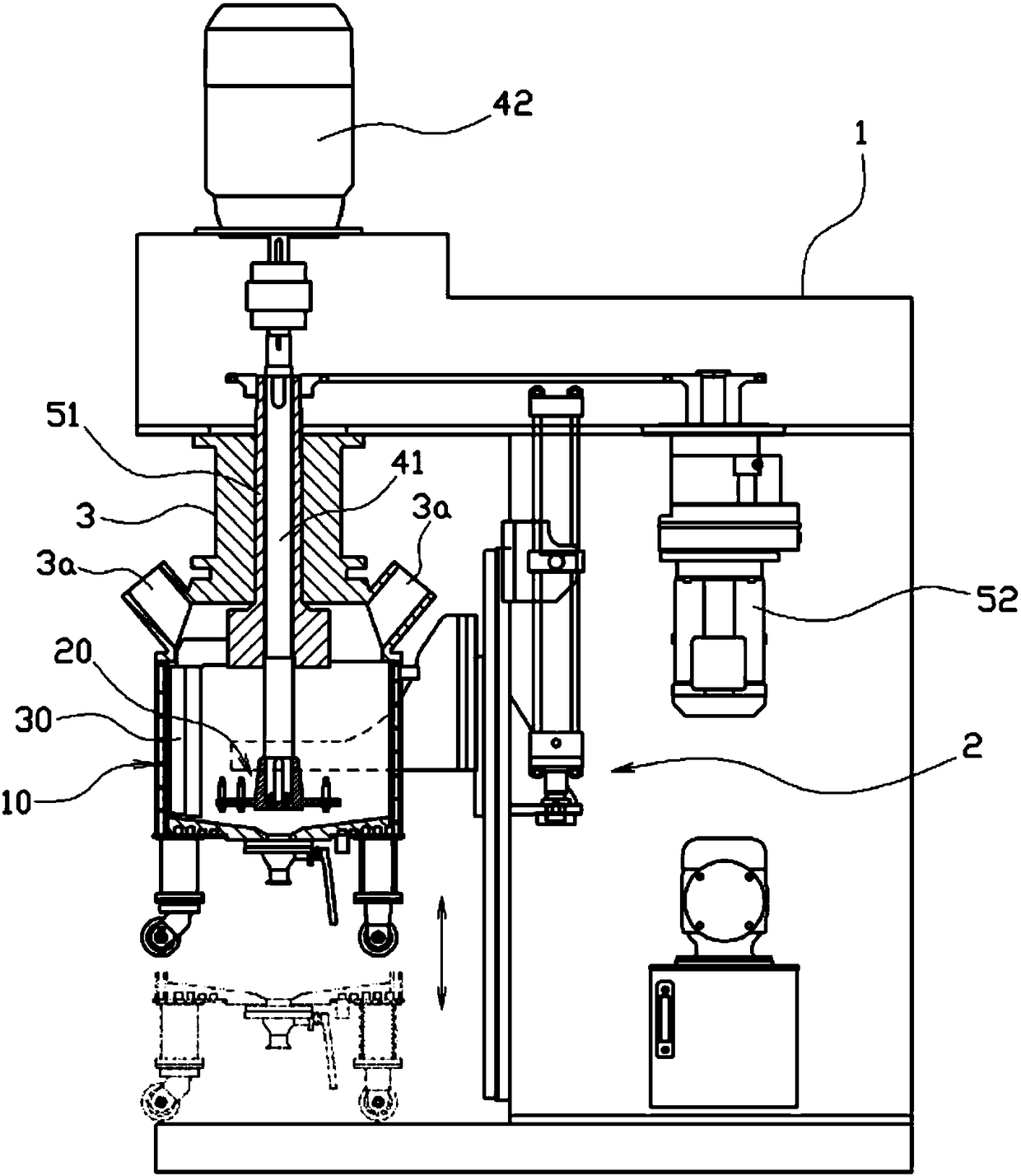

[0047] figure 1 by figure 2 It is a cross-sectional view showing a slurry mixer for battery electrodes according to the present invention. As shown in the figure, it has a container 10 that can accommodate the mixed material for manufacturing the slurry for battery electrodes. The bottom 11 of the container 10 is formed from the center toward The sloped bottom surface 12 whose outer side gradually becomes higher forms an inner peripheral surface 14 standing upright from the edge of the sloped bottom surface 12 on the side wall 13 of the container 10 .

[0048] The container 10 is arranged on the main body of the mixer 1, and can be moved up and down by the lifting tool 2 composed of a driving cylinder and a guide rail. The upper part can be opened and closed by the cover 3 provided on the main body 1 of the mixer. The inlet 3a inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com