Wafer biscuit baking oven

A wafer and oven technology, which is used in food ovens, ovens loading/unloading, baking, etc. The effect of saving gas, balanced color and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

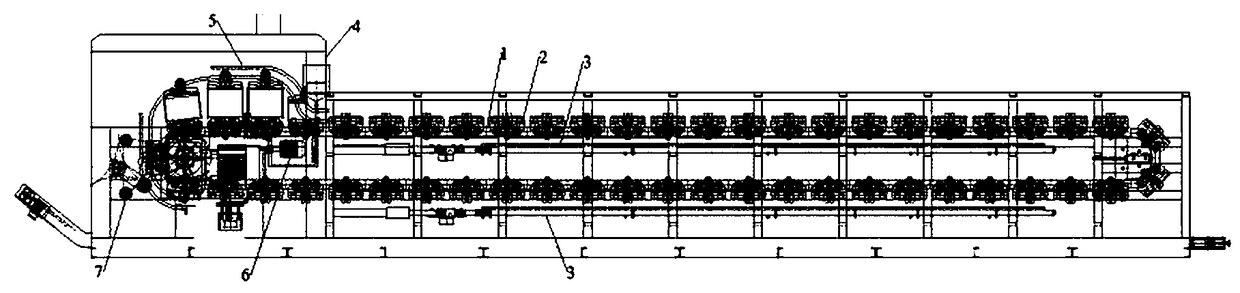

[0040] Please refer to figure 1 , the present embodiment provides a wafer oven, comprising a wafer transport chain assembly 1, a number of wafer molds 2 arranged on the wafer transport chain assembly 1, respectively arranged on the wafer transport chain assembly 1 The two gas components 3 at the bottom and the middle, the chassis 4 set at one end of the wafer conveyor chain component 1 and partially wrapping the wafer conveyor chain component 1, the mold opening and closing component 5 set in the chassis 4, and the chassis 4 4, and the discharge joint assembly 7 arranged in the cabinet 4. Through the mutual cooperation of the wafer transport chain assembly 1, wafer mold 2, gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com