Four-axis linkage pressurized equipment based on diamond anvil cell press

A diamond-to-top, four-axis linkage technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of sample cavity deformation, diamond crushing, uneven pressure, etc., and achieve improvement The effect of reliability and success rate, improvement of control freedom, and convenience of experiment progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the scope of protection of the present invention is not limited to the range expressed in the examples.

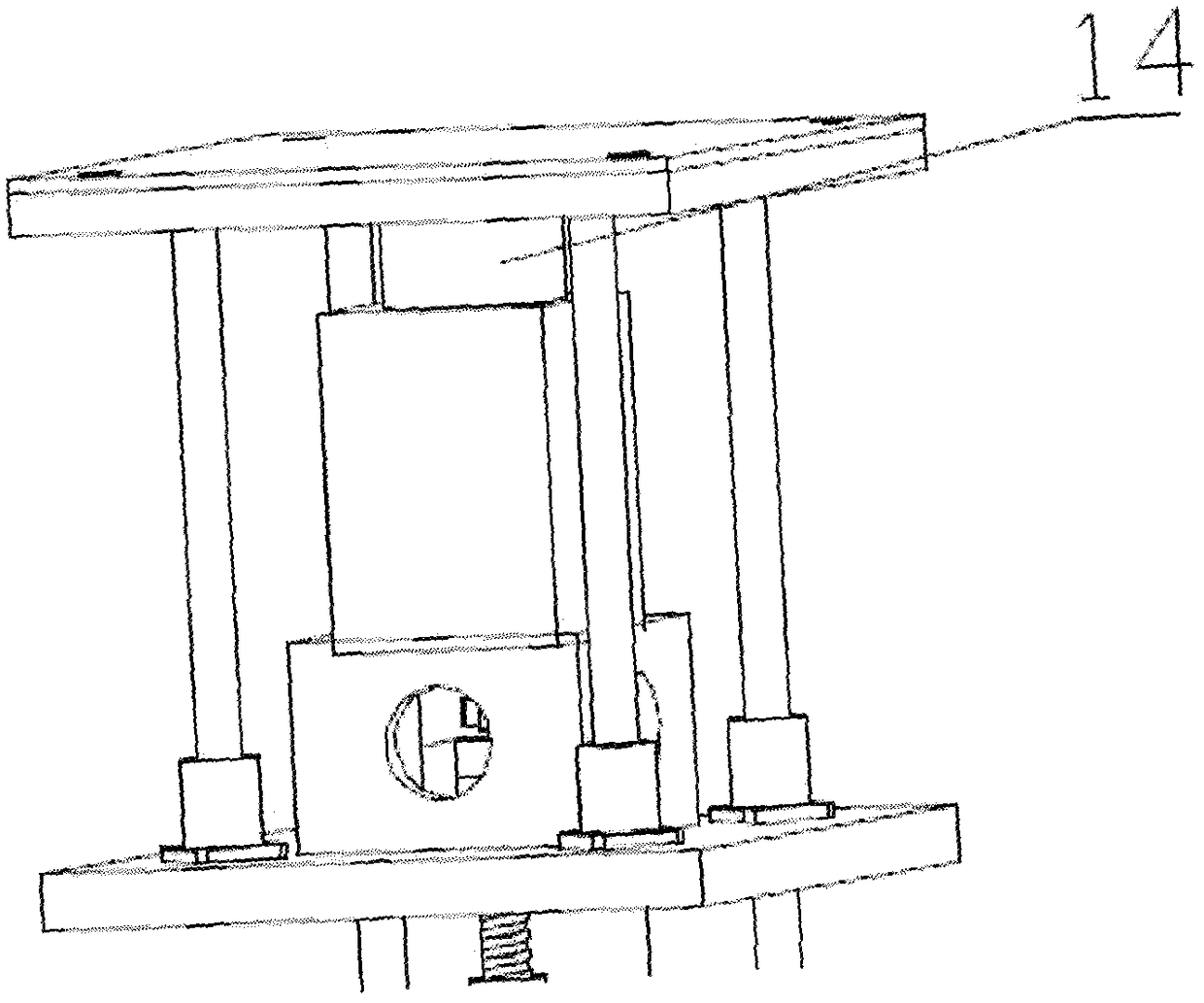

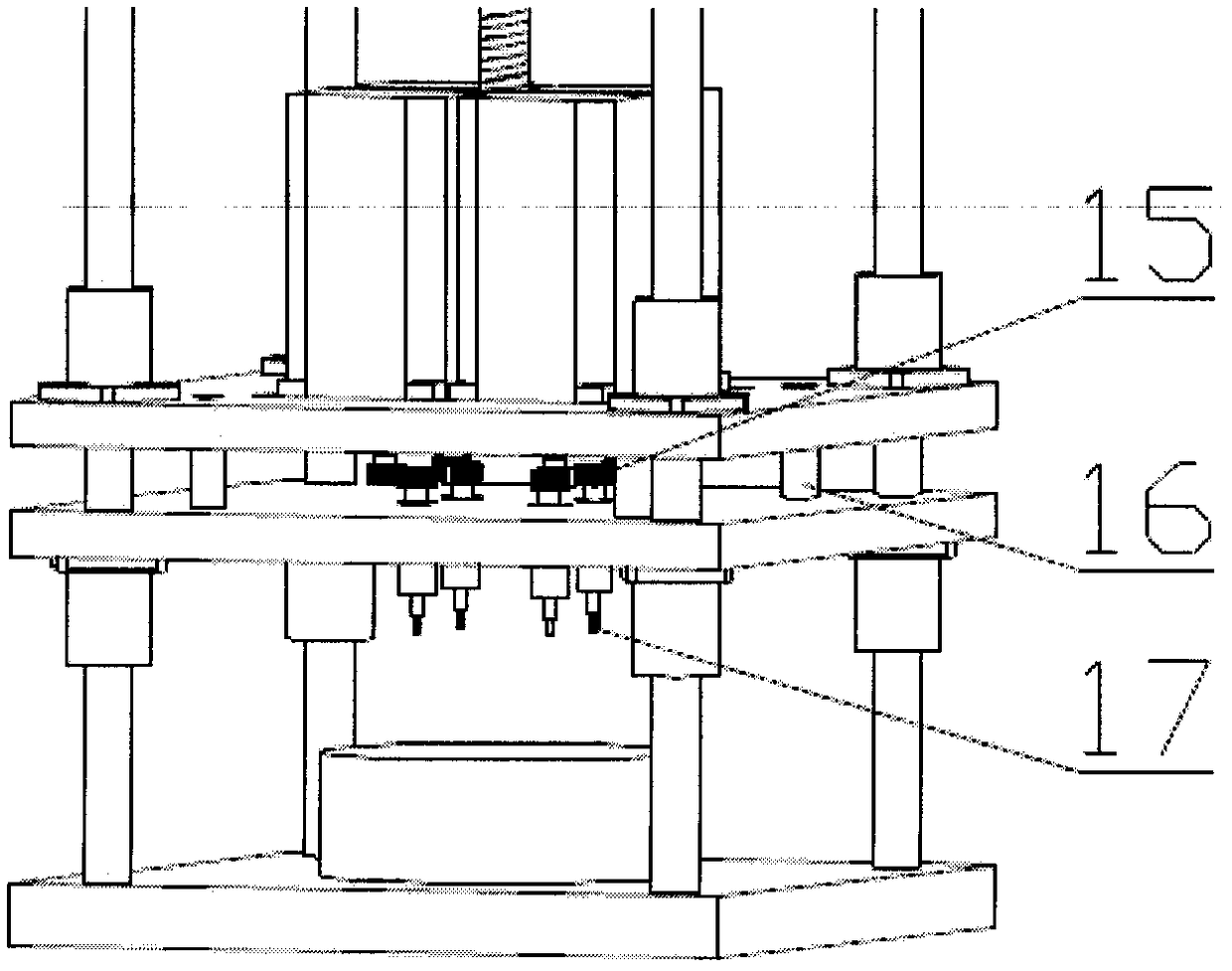

[0020] Referring to the accompanying drawings, the present invention provides a synchronous loading device based on a diamond-to-anvil press, which is realized through the following technical solutions: use four motors to simultaneously rotate the booster bolts, and input the same torque to apply static water to the experimental sample. Pressure, overcome the unfavorable factors of uneven pressure on the sample in the step-by-step pressurization mode of the material, protect the sample cavity, and improve the success rate of the experiment. Apply hydrostatic pressure to the sample chamber to improve the reliability of the experiment, which specifically includes the following steps:

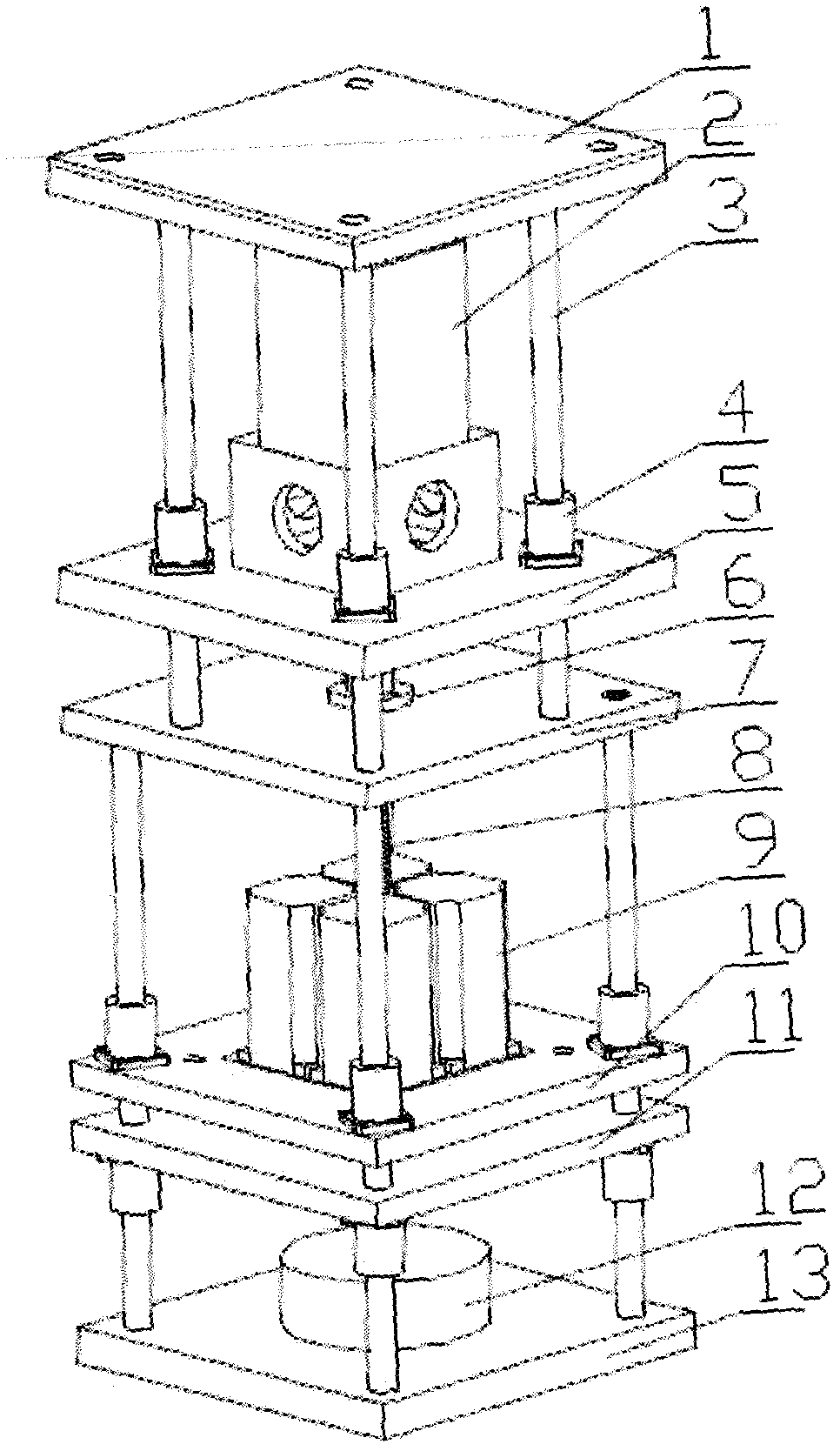

[0021] On the frame composed of the polished rod 3, the load plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com