A double-layer vortex secondary air system for a garbage incinerator

A waste incinerator and secondary air technology, applied in incinerators, combustion types, combustion equipment, etc., can solve the problems of multi-pollutants, poor regulation performance, poor flue gas stirring effect, etc., to improve combustion efficiency, CO concentration The effect of reducing and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

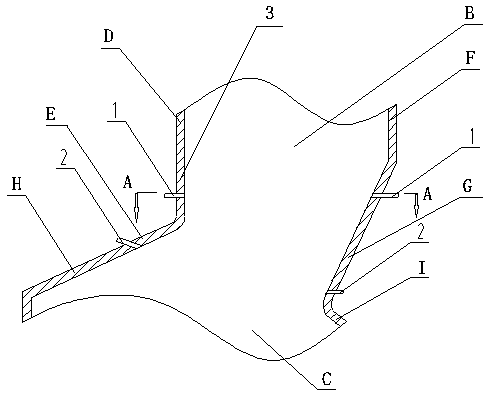

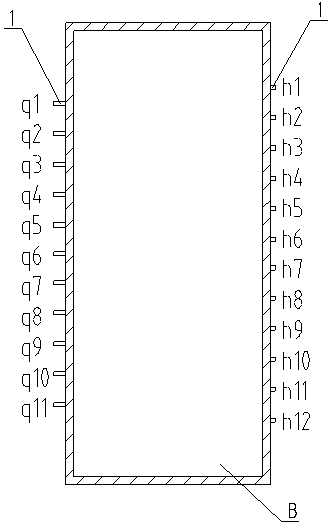

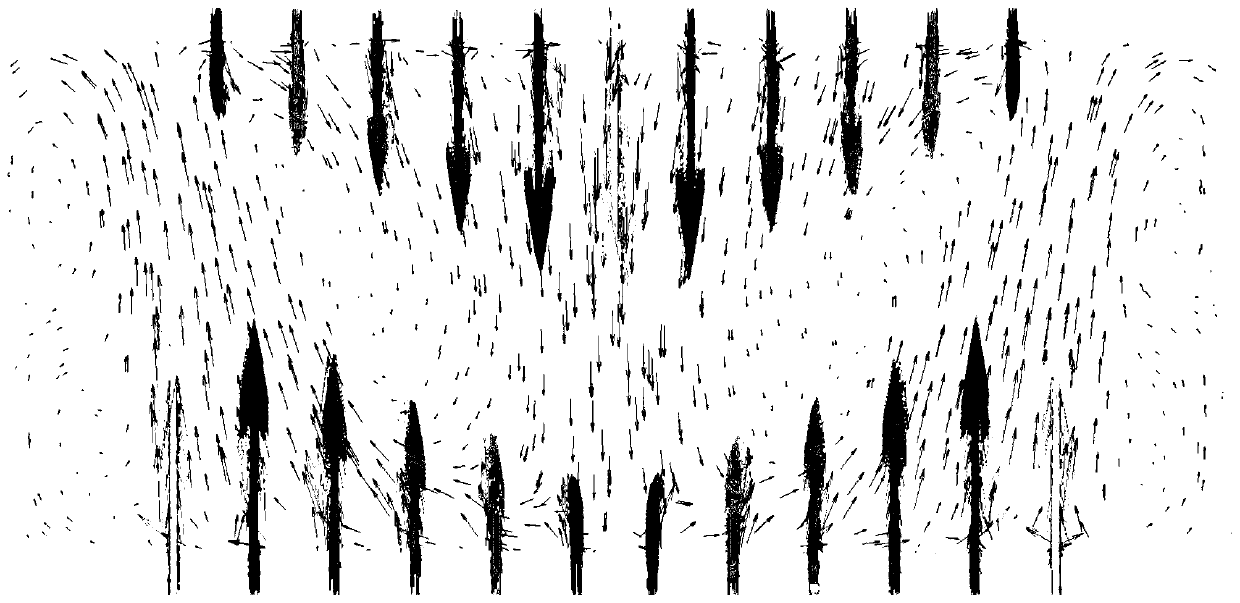

[0013] Referring to the accompanying drawings, a double-layer vortex secondary air system for a garbage incinerator includes an upper vortex secondary air nozzle 1, a lower secondary air nozzle 2, and a garbage incinerator body 3. The upper part of the garbage incinerator body 3 is The upper furnace B, the lower part of the garbage incinerator body 3 is the lower combustion chamber C, the upper layer vortex secondary air nozzle 1 is set at the junction of the front wall section D of the garbage incinerator body 3 and the middle section E of the front wall, and the rear of the garbage incinerator body 3 The upper vortex secondary air nozzle 1 is set at the connection between the wall section F and the rear wall middle section G, the lower secondary air nozzle 2 is set at the connection between the front wall middle section E of the garbage incinerator body 3 and the front wall lower section H, and the garbage incinerator body 3 The lower secondary air nozzle 2 is arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com