A kind of printing and dyeing wastewater treatment method

A technology for printing and dyeing wastewater and treatment methods, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of poor removal of toxic substances and chroma, high raw material input costs, and difficulty in printing and dyeing water. To meet emission standards and other issues, to achieve the effect of less investment, energy saving and consumption reduction, and improvement of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

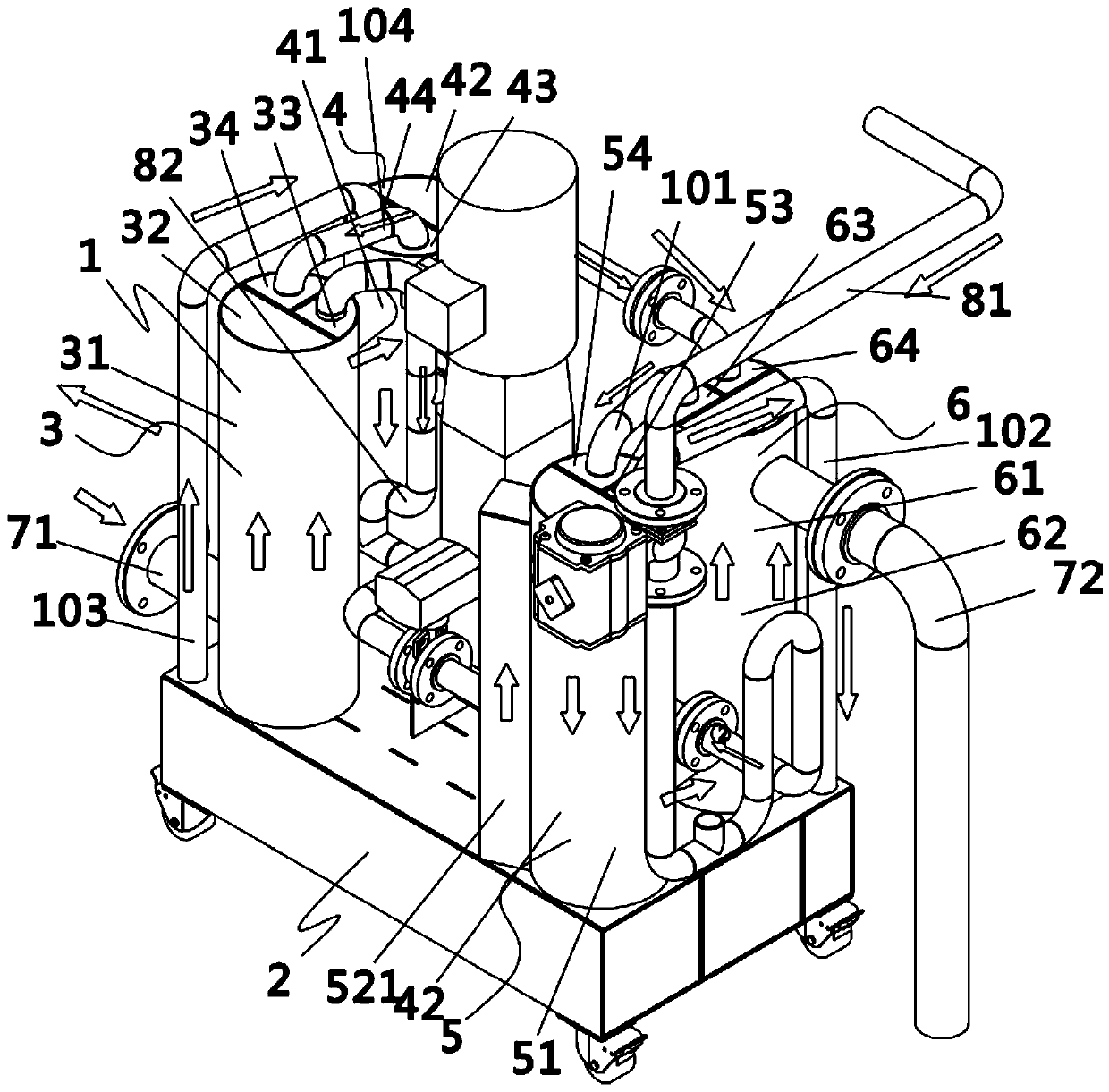

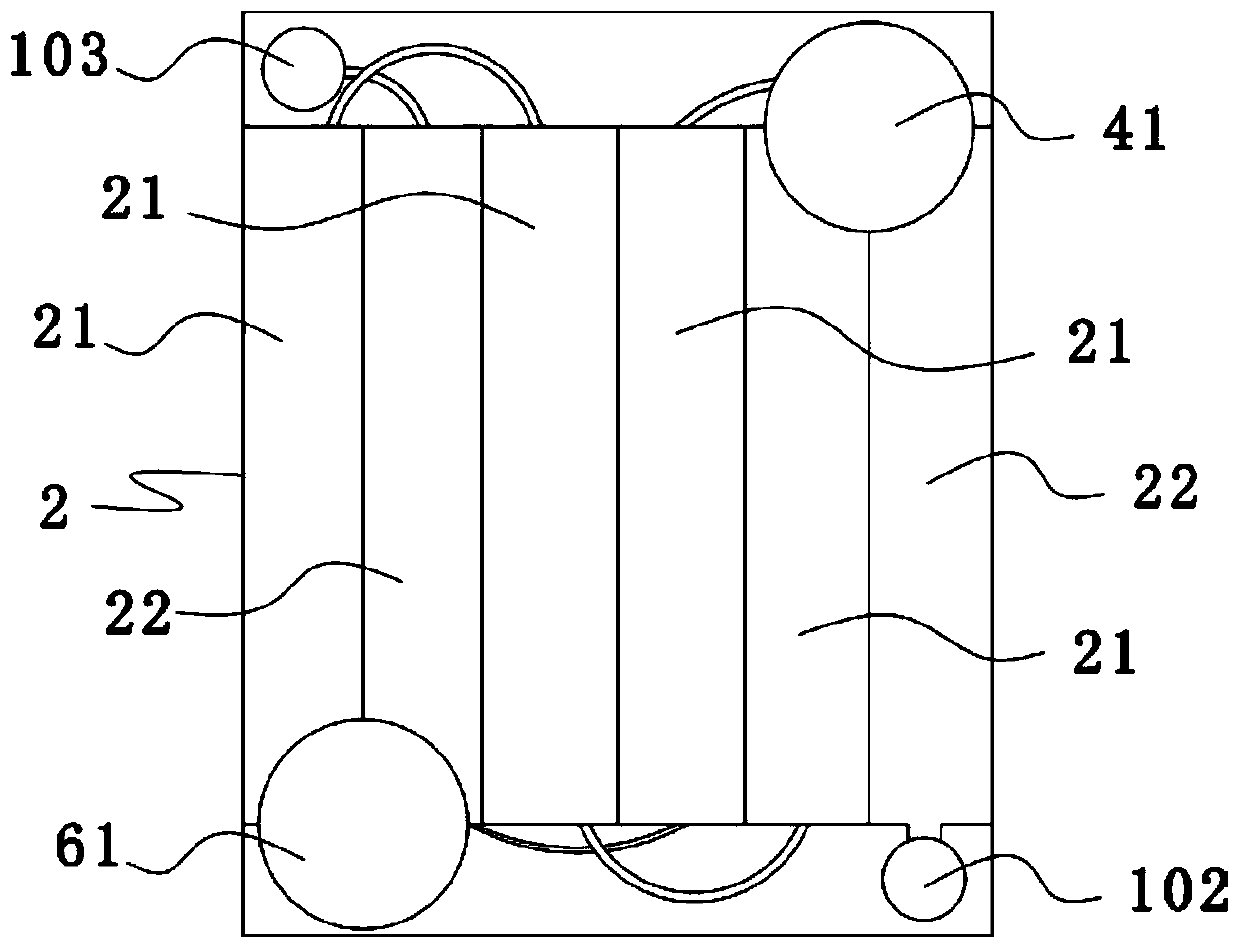

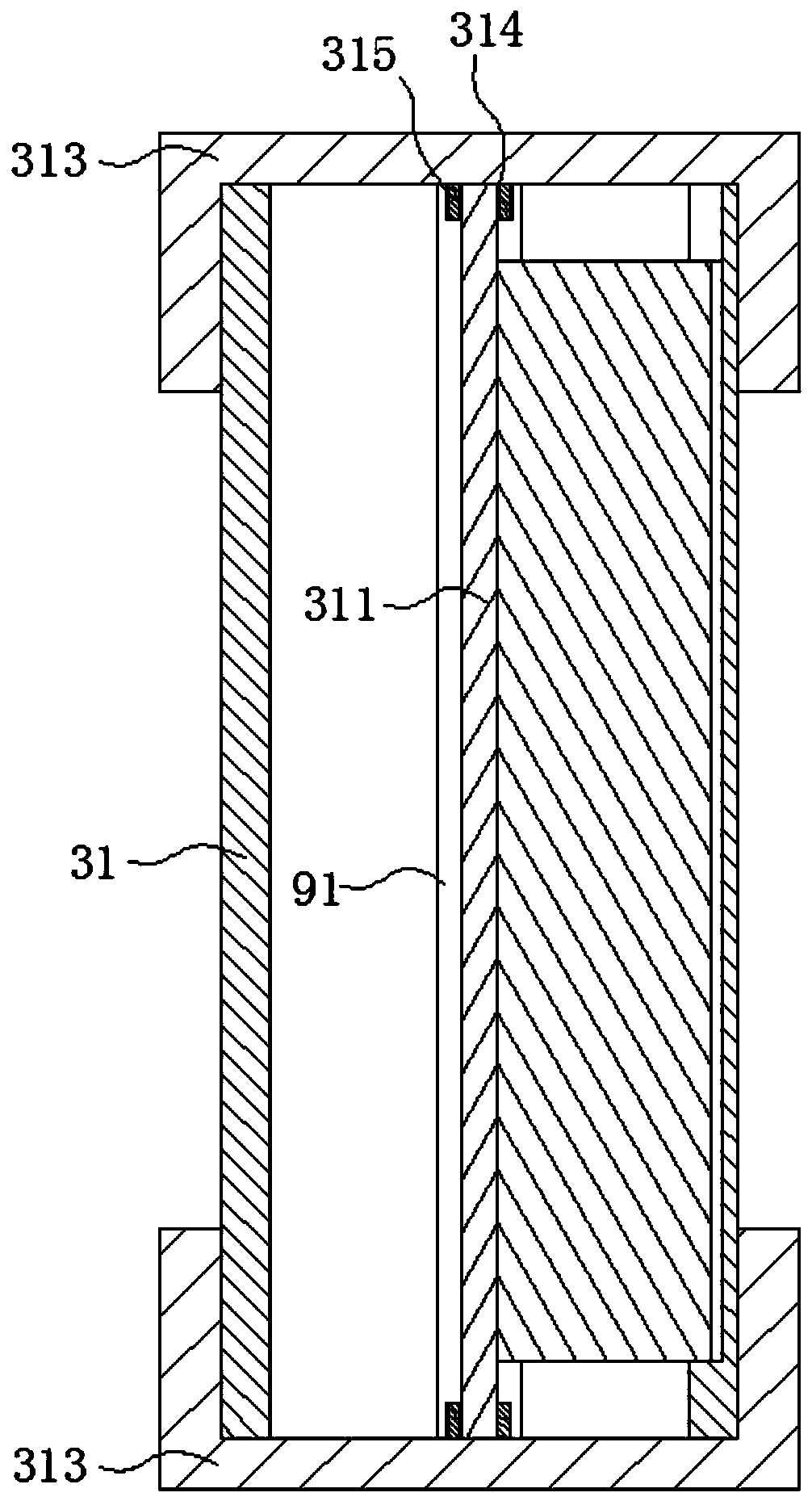

Image

Examples

Embodiment 1

[0025] A method for treating printing and dyeing wastewater, comprising the following steps: (1) passing the printing and dyeing wastewater into a regulating tank after heat exchange treatment through heat exchange equipment; the temperature of the printing and dyeing wastewater after heat exchange is 30°C; Add an acid-base regulator to adjust the pH to 8.5, and the COD to 300mg / L; specifically, the acid-base regulator includes the following components in parts by weight: 25 parts of citric acid, 2 parts of sodium hydroxide, and 1 part of hydrochloric acid solution; (2) Pass the waste water into the reaction pool, add basic resin into the reaction pool, the reaction pool is a concrete pool, and discharge the waste water after stirring and reacting for 1 hour; specifically, the basic resin is a strong basic anion exchange resin, after the reaction treatment The COD of the discharged wastewater is less than 50 mg / L, specifically 40 mg / L; (3) Add phosphate substances to the wastew...

Embodiment 2

[0040] A method for treating printing and dyeing wastewater, comprising the following steps: (1) passing the printing and dyeing wastewater into a regulating pool after heat exchange treatment by heat exchange equipment; the temperature of the printing and dyeing wastewater after heat exchange is 35°C; Add an acid-base regulator to adjust the pH to 9.5, and the COD to 500mg / L; specifically, the acid-base regulator includes the following components in parts by weight: 33 parts of citric acid, 4 parts of sodium hydroxide, and 3 parts of hydrochloric acid solution; (2) Pass the waste water into the reaction pool, add basic resin into the reaction pool, the reaction pool is a concrete pool, and discharge the waste water after stirring and reacting for 2 hours; specifically, the basic resin is a strong basic anion exchange resin, after the reaction treatment The COD of the discharged wastewater is less than 50 mg / L; (3) Add phosphate substances to the wastewater, specifically sodium...

Embodiment 3

[0042] A method for treating printing and dyeing wastewater, comprising the following steps: (1) passing the printing and dyeing wastewater into a regulating tank after heat exchange treatment through heat exchange equipment; the temperature of the printing and dyeing wastewater after heat exchange is 30°C; Add an acid-base regulator to adjust the pH to 8.5, and the COD to 300mg / L; specifically, the acid-base regulator includes the following components in parts by weight: 25 parts of citric acid, 4 parts of sodium hydroxide, and 1 part of hydrochloric acid solution; (2) Pass the waste water into the reaction pool, add basic resin into the reaction pool, the reaction pool is a concrete pool, and discharge the waste water after stirring and reacting for 1.5h; specifically, the basic resin is a strongly basic anion exchange resin, which is treated by reaction The COD of the discharged wastewater is less than 50 mg / L; (3) Add phosphate substances to the wastewater, specifically sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com