An industrial acid sewage treatment device

A technology for acid sewage and treatment equipment, applied in water/sludge/sewage treatment, sustainable biological treatment, water aeration, etc., can solve the problems of reducing the amount of oxygen accumulation, leakage into the main pipe, etc., and achieve long service life , high degree of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

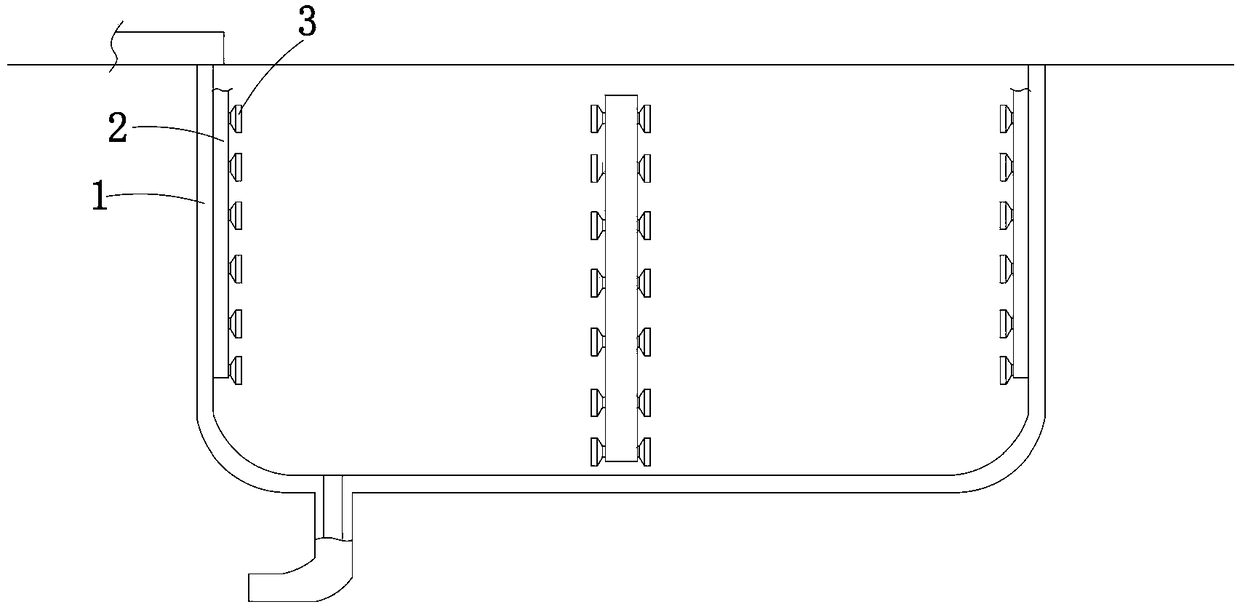

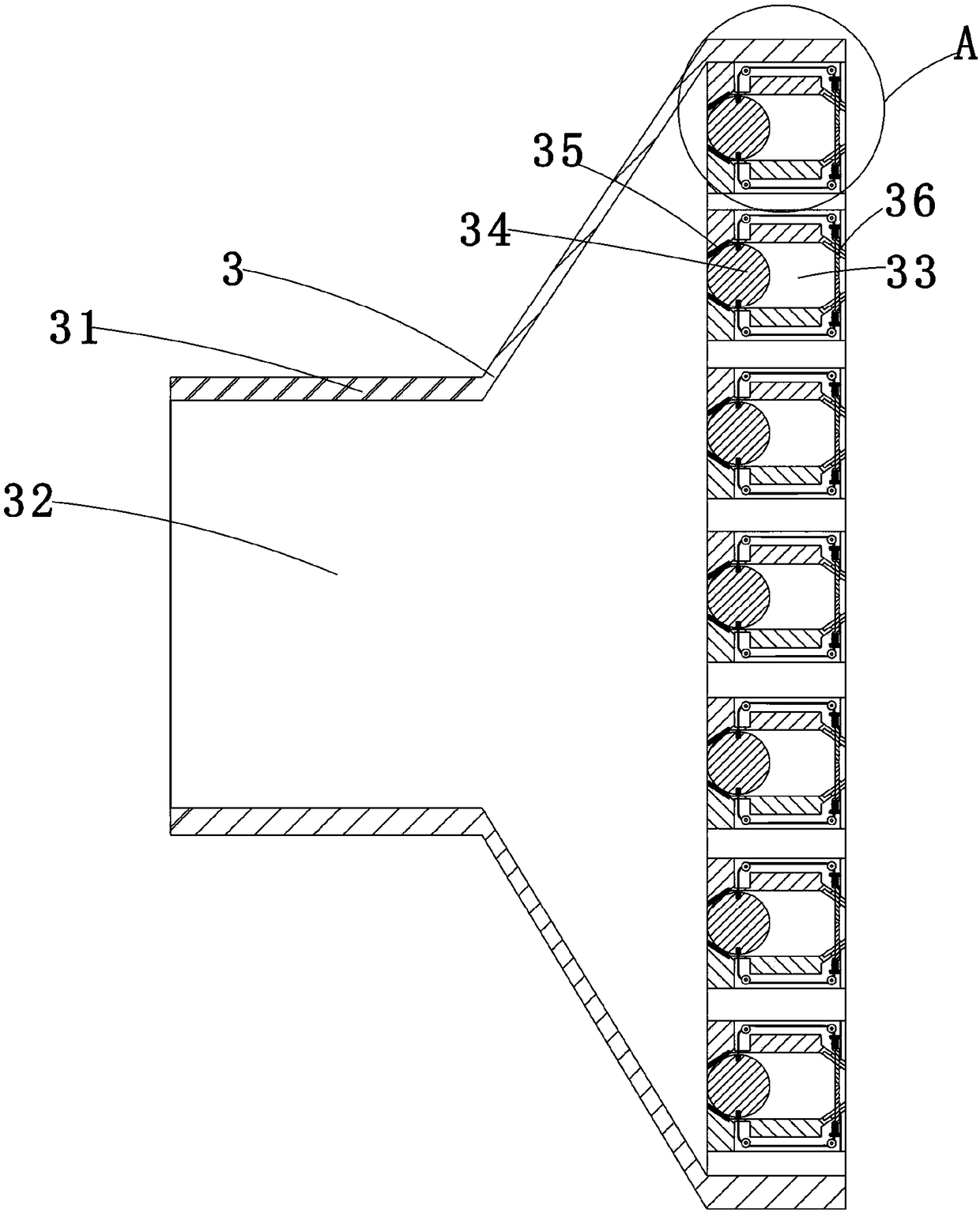

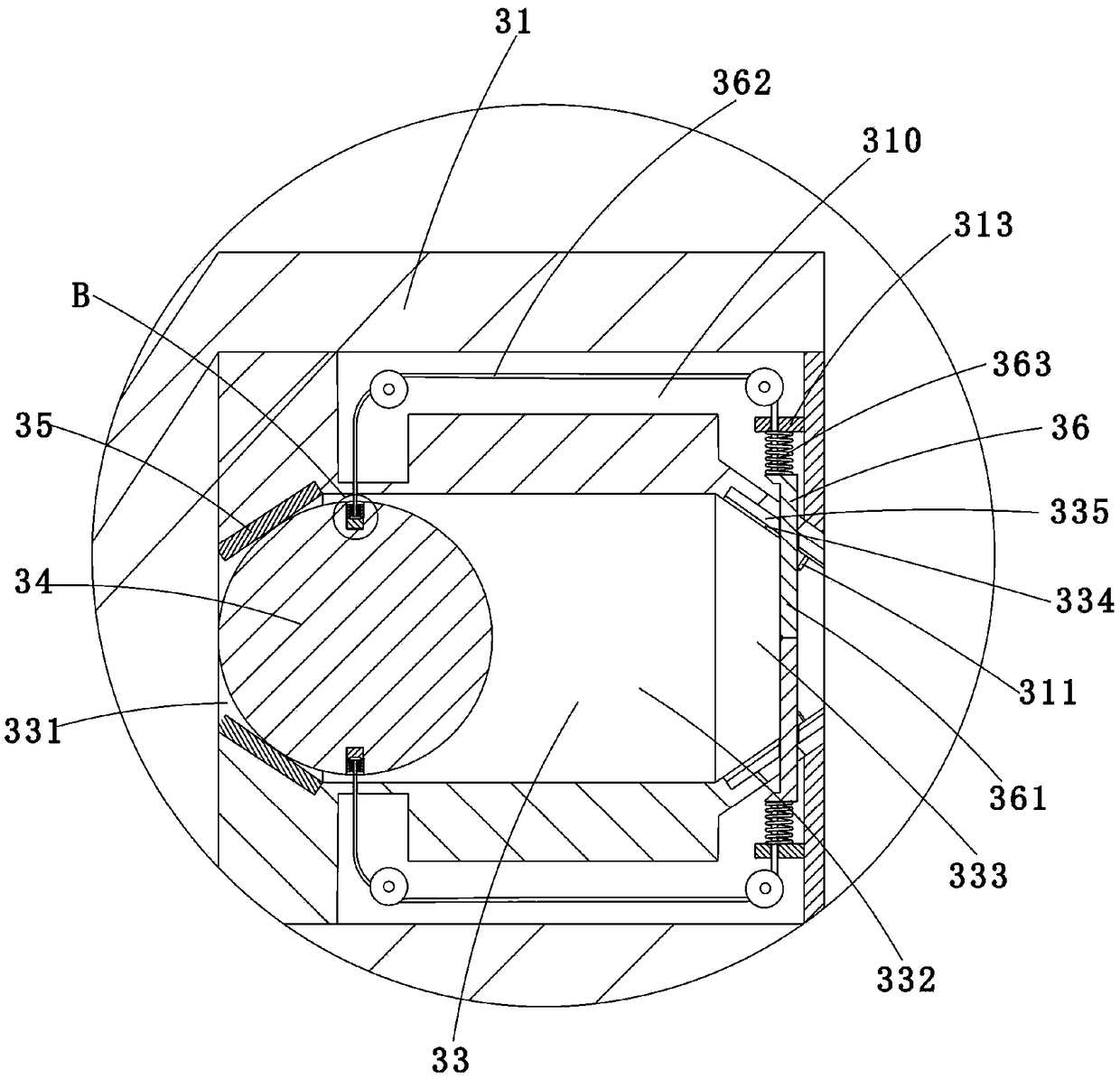

[0021] Such as Figure 1-5 As shown, a kind of industrial acid sewage treatment device comprises pool body 1, oxygen supply pipeline 2 and aeration part 3; Wherein said pool body 1 is a metal pool, and the top of this pool body 1 is provided with water inlet pipe, The lower part is provided with a water outlet pipeline; the oxygen supply pipeline 2 is a metal pipeline, and oxygen or compressed air is passed into the oxygen supply pipeline 2, and the oxygen supply pipeline 2 is arranged along the side wall of the pool body 1, and The middle part of the pool body 1 is also inserted with an oxygen supply pipeline 2; the aeration component 3 includes a base 31, a main pipe 32 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com