Two-way translation material conveying robot, material conveying system and walking control method of material conveying robot

A walking control and transportation system technology, which is applied in two-dimensional position/channel control, transportation and packaging, motor vehicles, etc., can solve the problems of space occupied by physical tracks in the site, affecting the use of the site, prone to rollover, etc., to achieve Invoke flexibility, optimize site use, and eliminate effects of turning movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

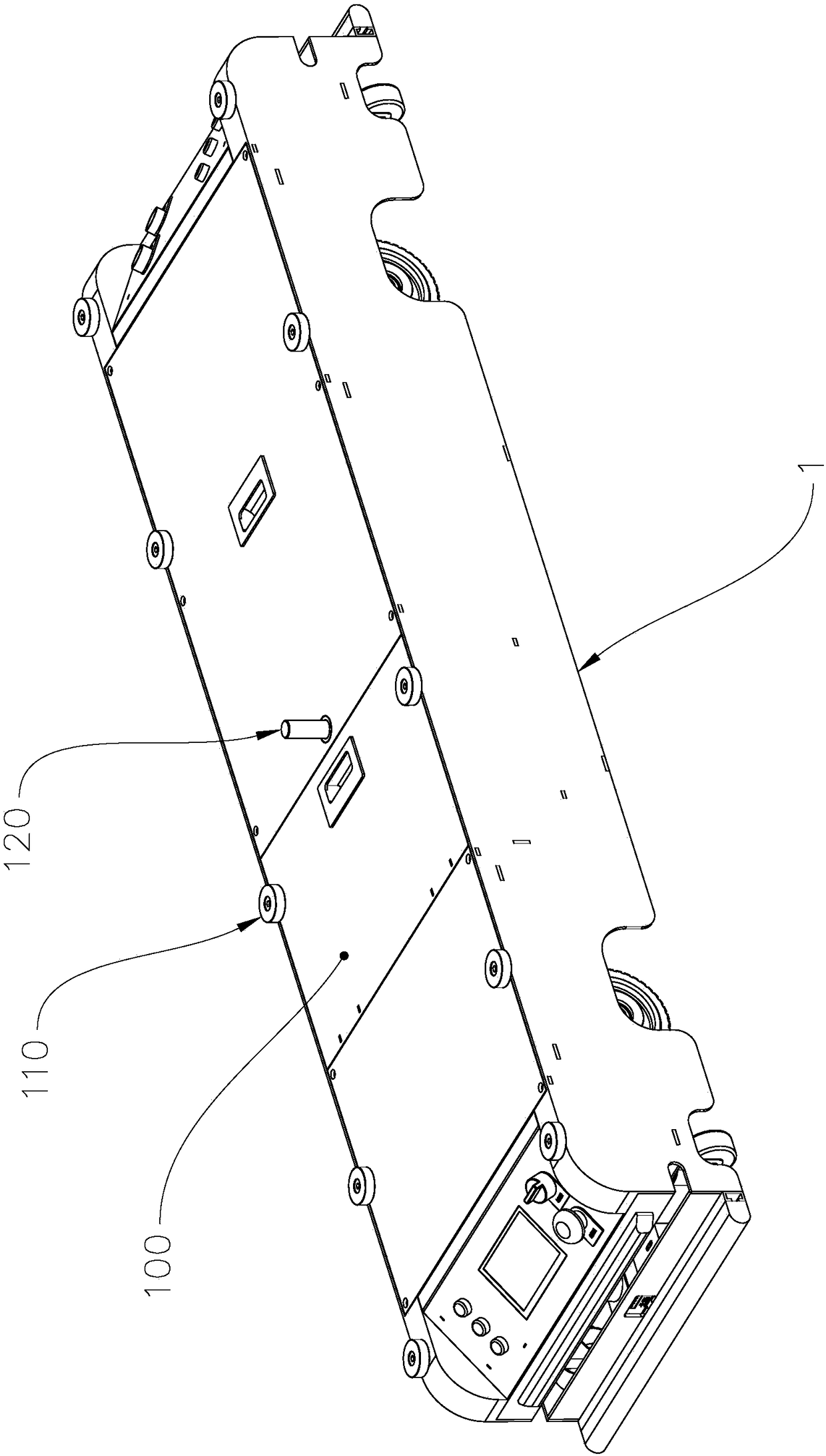

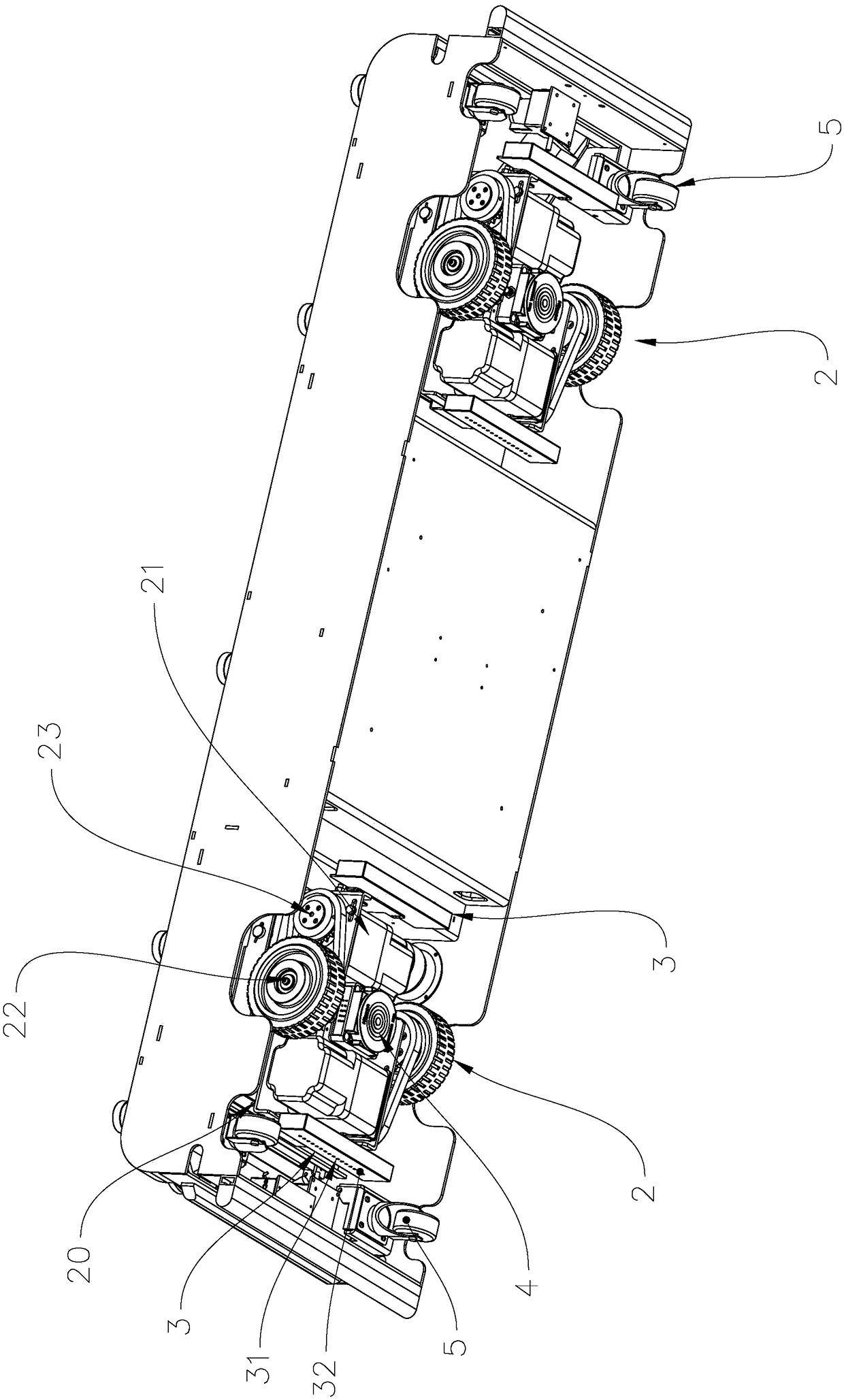

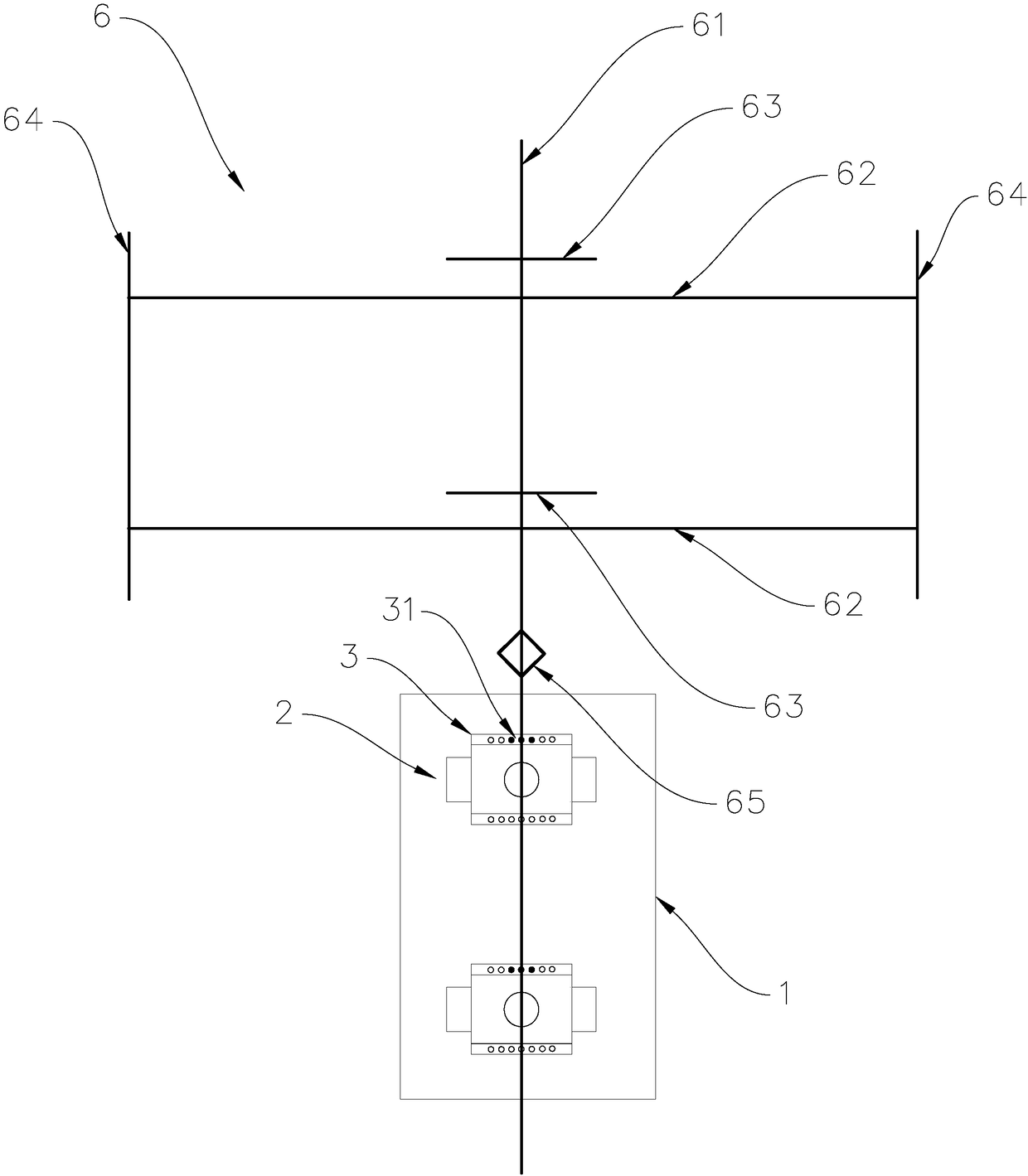

[0040] see figure 1 and figure 2 , figure 1 and figure 2 They are structural diagrams of different perspectives of the embodiment of the bidirectional translational material transport robot of the present invention. The two-way translational material transportation robot provided by the present invention is an AGV automatic guided transport vehicle, and the two-way translational material transportation robot includes a long main body 1 and two sets of driving wheels 2 arranged below the main body 1, a load-bearing wheel set and an RFID reader 4. The bearing wheel set includes four universal wheels 5 arranged on the four corners of the bottom of the main body 1 . Each drive wheel set 2 includes a connecting seat 20 , two drive motors 21 , two drive wheels 22 , two sets of transmission chain assemblies 23 and two tracking sensors 3 .

[0041] The connecting base 20 is rotatably connected to the bottom of the main body 1, and the two driving wheel sets 2 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com