Tire mold vulcanizing device

A tire mold, No. 1 technology, applied to tires, household appliances, and other household appliances, etc., can solve the problems of harmful substances in exhaust gas, prone to skewing of valve core, inaccurate spring adjustment, etc., to achieve convenient use and ensure exhaust effect , good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

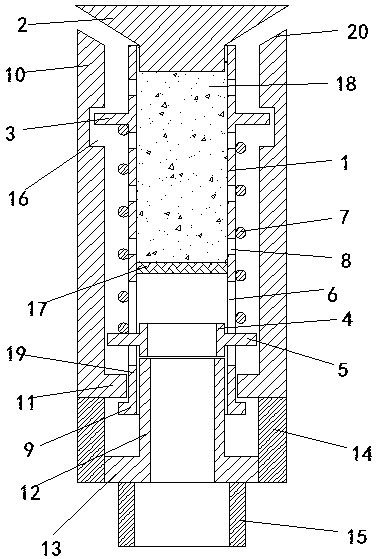

[0021] A cylindrical valve body 10 is inserted in the exhaust hole, and the valve body 10 is arranged longitudinally. The bottom of the valve body 10 is provided with a limiting neck 11, and a cylindrical valve core 1 is inserted in the valve body 10, and the valve core 1 is uniformly ringed. Two strip-shaped through holes 6 are provided, and the two strip-shaped through holes 6 are arranged vertically;

[0022] The spool 1 is inserted with a limit ring 4, and the limit ring 4 is provided with two No. 1 limit blocks 5, and the two No. 1 limit blocks 5 cooperate with two strip-shaped through holes 6;

[0023] The bottom end of the spool 1 is coaxially provided with a No. 1 connecting ring 19. The No. 1 connecting ring 19 matches the shape of the spool 1. The outer edge of the connecting ring 19 is provided with a No. 2 limit block 9, and the No. 2 limit block 9 is arranged on the limit position. Below the necking 11; the second limit block 9 is ring-shaped;

[0024] The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com