A method for iron ore desulfurization

A technology of iron concentrate and ore slurry, which is applied in the field of metallurgy, can solve the problems of low removal rate, need for improvement, and ineffective removal of particulate minerals, and achieve the effects of environmental friendliness, stable indicators, and excessive sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

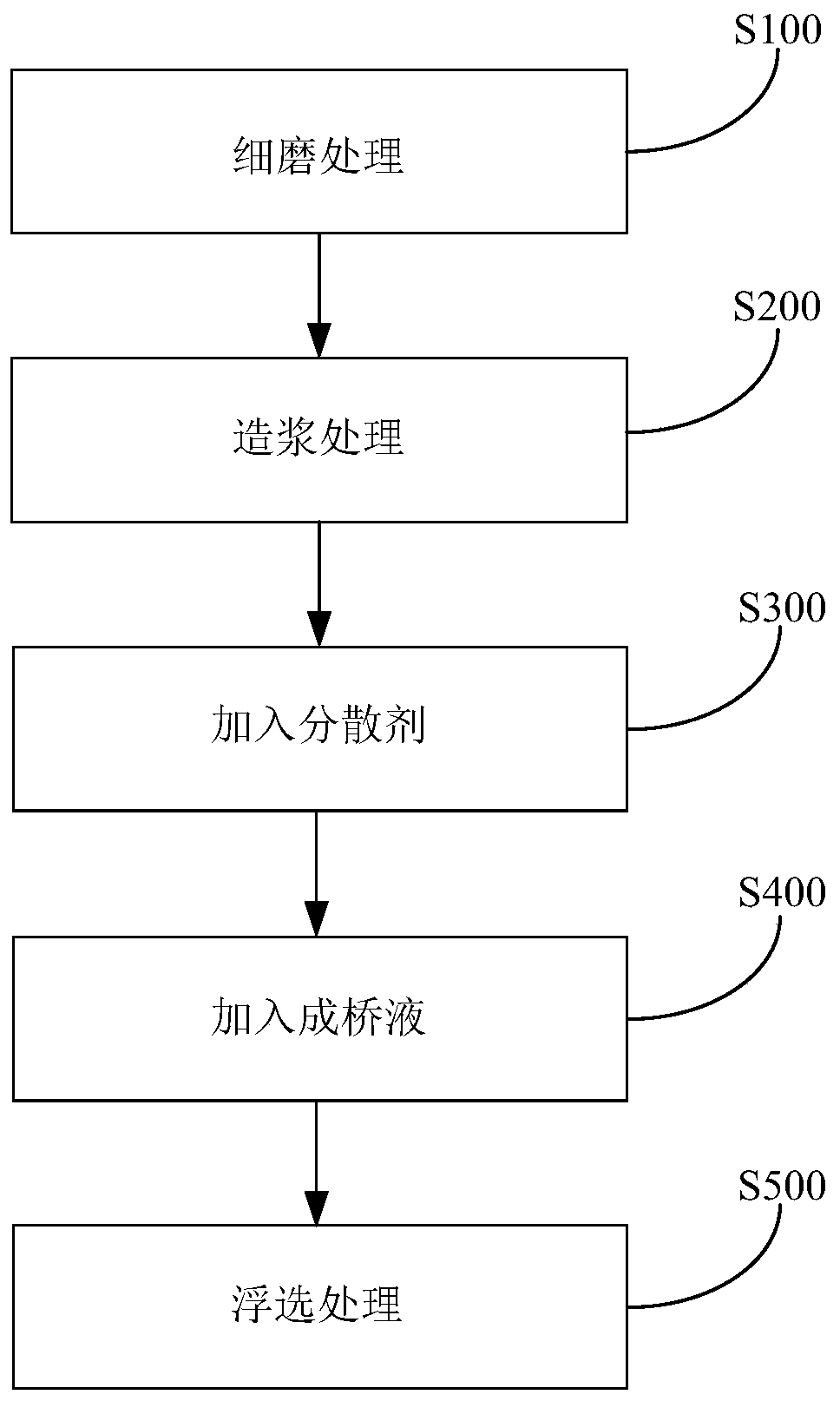

Method used

Image

Examples

Embodiment 1

[0052] Containing 4.4% of S in the iron concentrate gained from a certain copper mine in Anhui, the sulfur minerals are mainly pyrrhotite, adopt the iron concentrate desulfurization method of the present invention, and process it according to the following steps:

[0053] (1) Finely grinding the iron ore concentrate to obtain iron ore concentrate powder;

[0054] (2) mixing the iron ore concentrate powder with water to obtain a first slurry with a concentration of 38%;

[0055] (3) mixing the first pulp with sodium hexametaphosphate to obtain the second pulp; wherein the mass ratio of sodium hexametaphosphate to the first pulp is 2:10000;

[0056] (4) mixing the second pulp with sodium oleate and stirring for 5 to 10 minutes to obtain the third pulp; wherein the mass ratio of sodium oleate to the second pulp is 1:10000;

[0057] (5) Carry out flotation treatment to the third pulp, through primary roughing and secondary sweeping, the sulfur content in the iron ore concentrate ...

Embodiment 2

[0059] Containing 3.6% of S in the iron concentrate obtained from a certain iron mine in Hebei, the sulfur minerals are mainly pyrrhotite, adopt the iron concentrate desulfurization method of the present invention, and process it according to the following steps:

[0060] (1) Finely grinding the iron ore concentrate to obtain iron ore concentrate powder;

[0061] (2) mixing the iron ore concentrate powder with water to obtain a first slurry with a concentration of 40%;

[0062] (3) mixing the first pulp with sodium hexametaphosphate to obtain the second pulp; wherein the mass ratio of sodium hexametaphosphate to the first pulp is 1.5:10000;

[0063] (4) mixing the second pulp with sodium oleate and stirring for 5 to 10 minutes to obtain the third pulp; wherein the mass ratio of sodium oleate to the second pulp is 1.5:10000;

[0064] (5) Flotation treatment is carried out to the third pulp, and through primary roughing and secondary sweeping, the sulfur content in the iron con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com