Method for desulfurizing of iron ore concentrate

A technology for iron concentrate and pulp, applied in the field of metallurgy, can solve the problems of low removal rate, ineffective removal of particulate-level minerals, and needs to be improved, and achieves the effect of being environmentally friendly, solving the problem of excessive sulfur content and stable indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

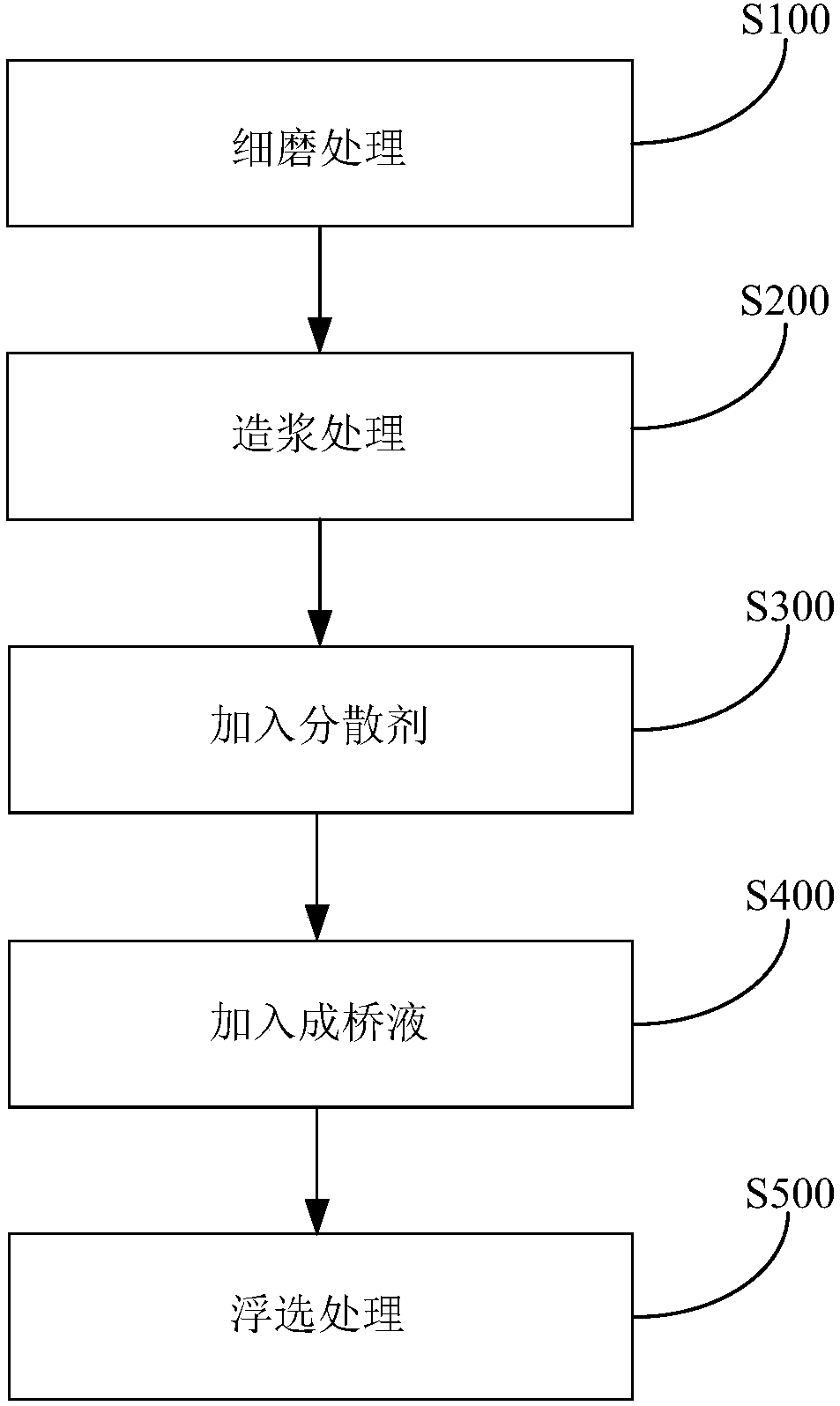

[0052] Containing 4.4% of S in the iron concentrate obtained from a certain copper mine in Anhui, the sulfur minerals are mainly pyrrhotite, adopt the iron concentrate desulfurization method of the present invention, and process it according to the following steps:

[0053] (1) Finely grinding the iron ore concentrate to obtain iron ore concentrate powder;

[0054] (2) mixing the iron ore concentrate powder with water to obtain a first slurry with a concentration of 38%;

[0055] (3) mixing the first pulp with sodium hexametaphosphate to obtain the second pulp; wherein the mass ratio of sodium hexametaphosphate to the first pulp is 2:10000;

[0056] (4) mixing the second pulp with sodium oleate and stirring for 5 to 10 minutes to obtain the third pulp; wherein the mass ratio of sodium oleate to the second pulp is 1:10000;

[0057] (5) Flotation treatment is carried out to the third pulp, and through primary roughing and secondary sweeping, the sulfur content in the iron conce...

Embodiment 2

[0059] Containing 3.6% of S in the iron concentrate gained from a certain iron mine in Hebei, the sulfur minerals are mainly pyrrhotite, adopt the iron concentrate desulfurization method of the present invention, and process it according to the following steps:

[0060] (1) Finely grinding the iron ore concentrate to obtain iron ore concentrate powder;

[0061] (2) mixing the iron ore concentrate powder with water to obtain a first slurry with a concentration of 40%;

[0062] (3) mixing the first pulp with sodium hexametaphosphate to obtain the second pulp; wherein the mass ratio of sodium hexametaphosphate to the first pulp is 1.5:10000;

[0063] (4) mixing the second pulp with sodium oleate and stirring for 5 to 10 minutes to obtain the third pulp; wherein the mass ratio of sodium oleate to the second pulp is 1.5:10000;

[0064] (5) Carry out flotation treatment to the third ore pulp, and through primary roughing and secondary sweeping, the sulfur content in the iron concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com