Coke oven gas TSA impurity removal regeneration gas recycling method and device

A technology for regenerative gas and coke oven gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as excessive sulfur content, and achieve the effects of ensuring environmental protection standards and discharge, ensuring stable operation, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

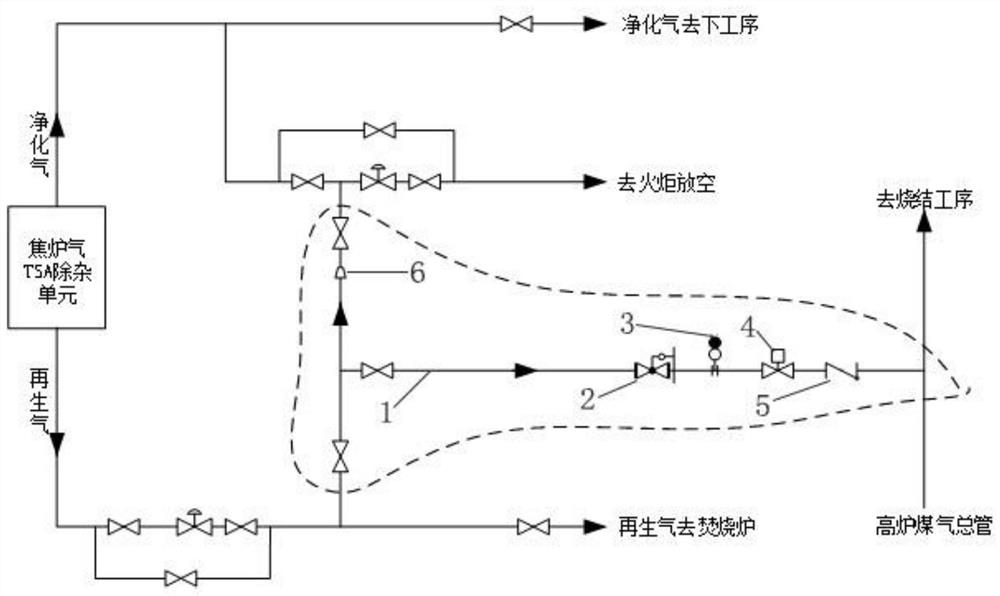

Image

Examples

Embodiment 1

[0021] A method for recovering and utilizing coke oven gas TSA impurity-removing regeneration gas. The coke oven gas TSA-removal regeneration gas is mixed with blast furnace gas through a regeneration gas pipeline, and then sent to the sintering process of the ironworks for use in the sintering process of the ironworks. Among them, the coke oven gas TSA impurity removal regeneration gas is mixed with the original blast furnace gas before the pressure is not lower than 15KPa, and the flow rate is 10000Nm 3 / h, coke oven gas TSA impurity removal regeneration gas mixed with the original blast furnace gas volume ratio of 1:50, coke oven gas TSA impurity removal regeneration gas mixed with the original blast furnace gas parameters: pressure 15KPa, temperature 40 ℃, The sulfur content is about 12mg / Nm 3 Rise to 17mg / Nm 3 , the sulfur content in the exhaust flue gas after use by downstream users of blast furnace gas shall not exceed 35mg / Nm 3 , to meet the national ultra-low emissi...

Embodiment 2

[0023] A method for recovering and utilizing coke oven gas TSA impurity-removing regeneration gas. The coke oven gas TSA-removal regeneration gas is mixed with blast furnace gas through a regeneration gas pipeline, and then sent to the sintering process of the ironworks for use in the sintering process of the ironworks. Among them, the coke oven gas TSA impurity removal regeneration gas is mixed with the original blast furnace gas before the pressure is not lower than 15KPa, and the flow rate is 15000Nm 3 / h, coke oven gas TSA impurity removal regeneration gas mixed with the original blast furnace gas volume ratio of 1:50, coke oven gas TSA impurity removal regeneration gas mixed with the original blast furnace gas parameters: pressure 15KPa, temperature 40 ℃, The sulfur content is about 12mg / Nm 3 Rise to 21mg / Nm 3 , the sulfur content in the exhaust flue gas after use by downstream users of blast furnace gas shall not exceed 35mg / Nm 3 , to meet the national ultra-low emissi...

Embodiment 3

[0025] A method for recovering and utilizing coke oven gas TSA impurity-removing regeneration gas. The coke oven gas TSA-removal regeneration gas is mixed with blast furnace gas through a regeneration gas pipeline, and then sent to the sintering process of the ironworks for use in the sintering process of the ironworks. Among them, the coke oven gas TSA impurity removal regeneration gas is mixed with the original blast furnace gas before the pressure is not less than 15KPa, and the flow rate is 12000Nm 3 / h, coke oven gas TSA impurity removal regeneration gas mixed with the original blast furnace gas volume ratio of 1:50, coke oven gas TSA impurity removal regeneration gas mixed with the original blast furnace gas parameters: pressure 15KPa, temperature 40 ℃, The sulfur content is about 12mg / Nm 3 Rise to 18mg / Nm 3 , the sulfur content in the exhaust flue gas after use by downstream users of blast furnace gas shall not exceed 35mg / Nm 3 , to meet the national ultra-low emissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com