A beam-column joint and its construction method

A beam-column joint and construction method technology, applied in construction, building construction and other directions, can solve the problems of high production and construction precision requirements, large formwork laying workload, long on-site construction period, etc., and achieves simple construction steps and formwork laying. The effect of small workload and short construction time on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

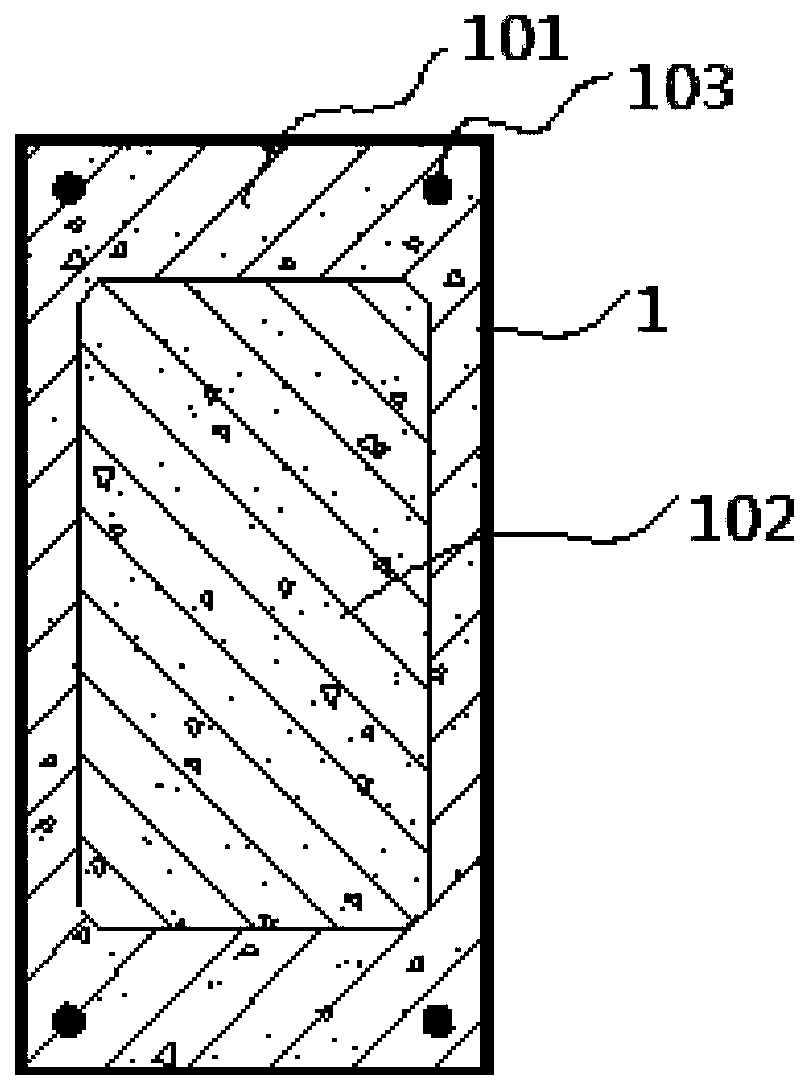

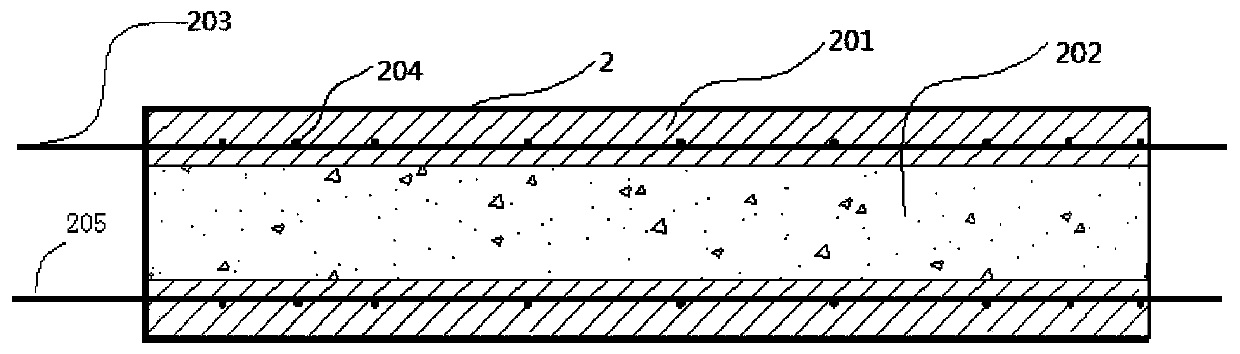

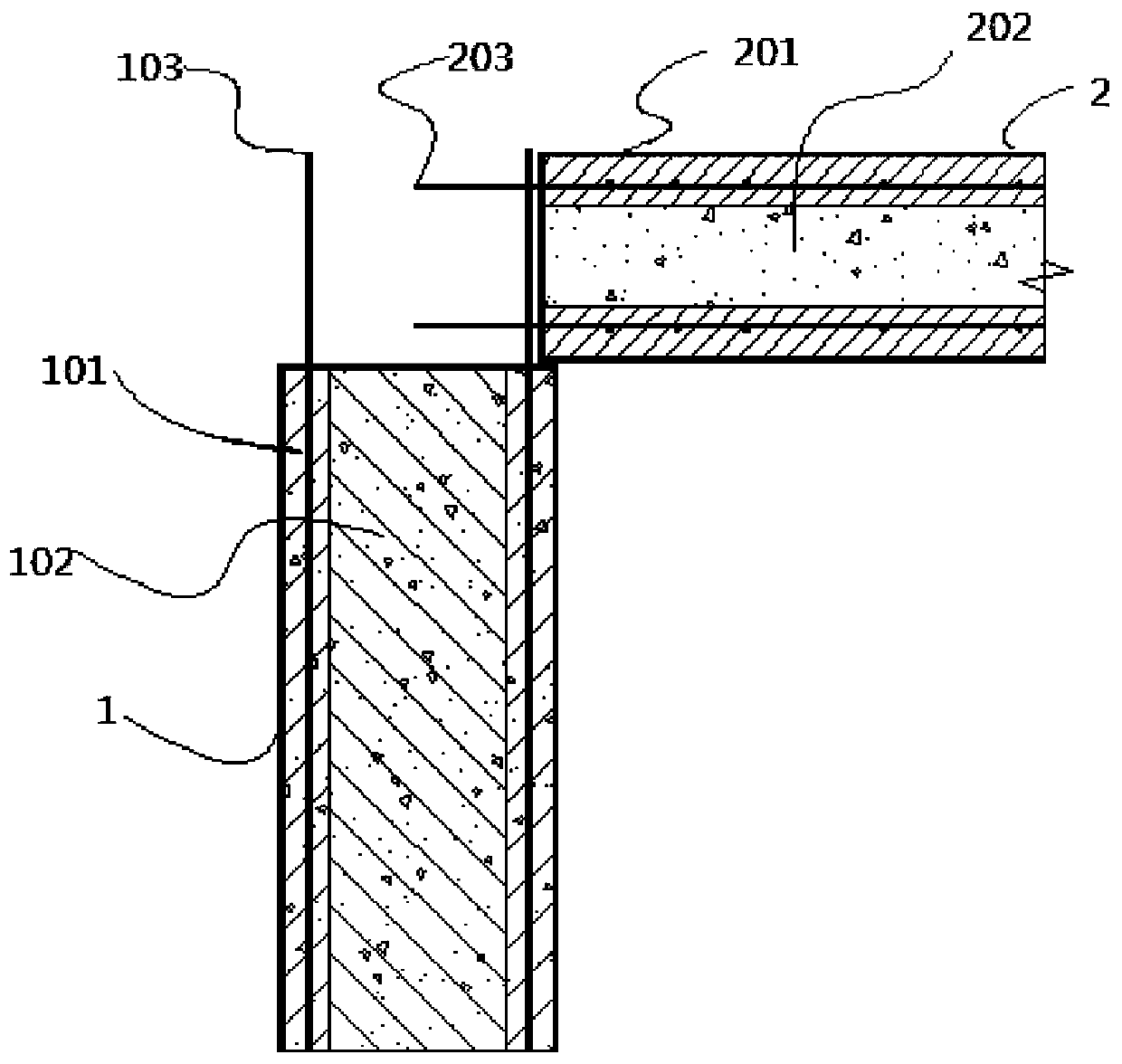

[0031] Reference attached Figure 1-3, a beam-column joint, including a composite column 1 and a composite beam 2, the composite column 1 includes a prefabricated column formwork 101 and a cast-in-place concrete column inner core 102, and the composite beam 2 includes a prefabricated beam formwork 201 and a cast-in-place concrete beam inner core 202, the top side of the prefabricated beam formwork 201 is provided with grouting holes and air vents (not shown in the figure), the prefabricated column formwork 101 of the composite column 1 and the prefabricated beam formwork 201 of the composite beam 2 are pre-embedded with hangers (not shown in the figure), prefabricated column formwork 101 is provided with column reinforcement 103 and stirrup (not shown in the figure), is provided with beam reinforcement 203,205 and stirrup 204 in prefabricated beam formwork 201, composite beam 2 The end 1-20cm is lapped on the top edge of the composite column 1, the composite beam 2 and the com...

Embodiment 2

[0046] The beam-column joint in this embodiment includes a composite column and two opposite composite beams (not shown in the figure) on the same straight line, and the end of the beam reinforcement is bent parallel to the end of the column reinforcement and anchored to the beam in the column node. Since the length of the beam reinforcement protruding from the prefabricated beam formwork and anchored in the beam-column joint is 35-40 times the diameter of the beam reinforcement, when the beam-column joint contains two opposite composite beams on the same straight line, the relative The beam reinforcement ends of the two composite beams are bent and then anchored to the beam-column joints, which can effectively solve the technical problem of insufficient accommodation space for the beam reinforcements of the two composite beams at the beam-column joints.

[0047] As an improvement of this embodiment, an elastic steel cable is provided at the node of the composite column and th...

Embodiment 3

[0049] The difference from Embodiment 1 and Embodiment 2 is that a beam-column joint in this embodiment includes a composite column 1 and a composite beam 2, and the cast-in-situ concrete column core 102 of the composite column 1 is also formed by pouring steel fiber concrete. The formula of the above-mentioned steel fiber concrete is 700-800 parts of Portland cement, 120-200 parts of power plant fly ash above grade II, 80-150 parts of silicon powder of 920U and above, 900-1100 parts of quartz sand, water-reducing 40-68 parts of agent, 150-175 parts of water, 75-100 parts of steel fiber with a length of 9-12 mm, and 200-400 parts of broken ceramic chips or construction crushed waste with a particle size of 0.1-35 mm. The beneficial effects of this embodiment are as follows: 1. The whole of the composite column is steel fiber concrete, compared with the prefabricated column of ordinary concrete or only the composite column of steel fiber concrete, its compressive capacity and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com