A local centralized power supply and control device for batch pneumatic doors

A centralized power supply and control device technology, applied in the direction of circuit devices, electrical program control, sequence/logic controller program control, etc., can solve the problems of inability to merge cables, heavy cable laying construction workload, and large cable consumption. Achieve the effects of reducing cable length, good economic benefits, popularization and application value, and saving cable consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

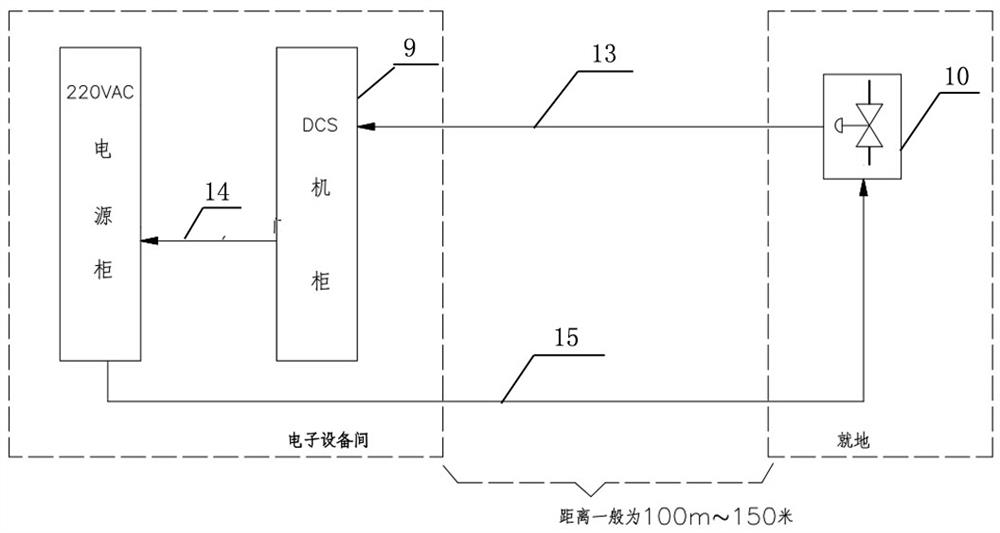

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

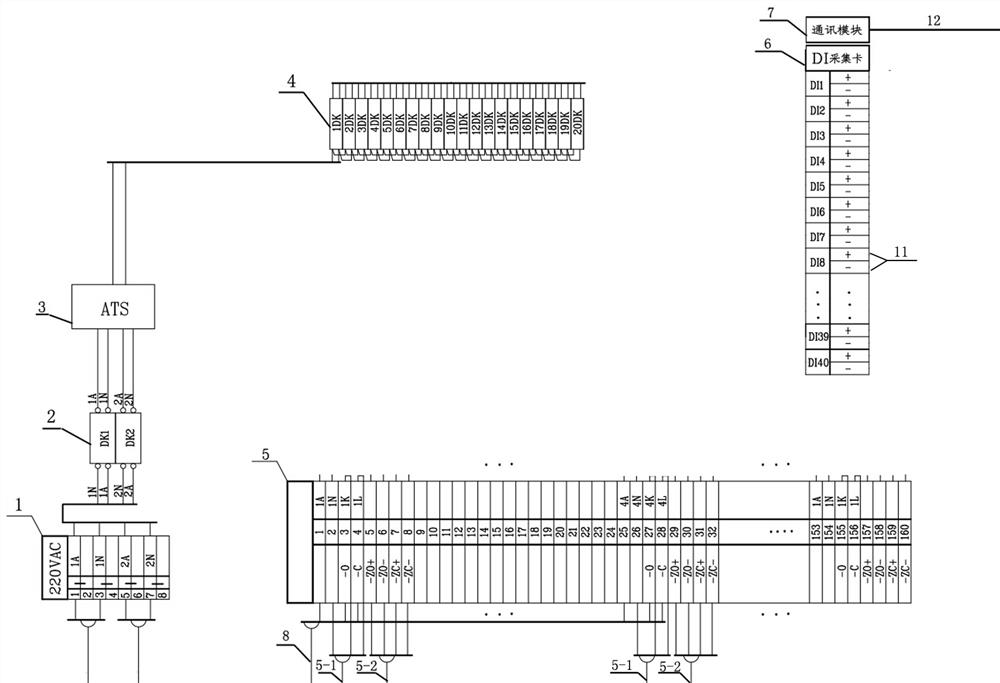

[0018] Such as image 3 As shown, a centralized power supply and control device for batch pneumatic doors is placed at the local end, including power supply incoming terminal block 1, main incoming power switch 2, dual power automatic switching device 3, power circuit switch 4, pneumatic The door power supply and control terminal block 5, the power supply incoming line terminal block 1, the main incoming line power switch 2, the dual power supply automatic switching device 3, the power circuit switch 4, the pneumatic door power supply and control terminal block 5 are connected in sequence, and the DI The signal data acquisition card 6 is connected to the power supply and control terminal block 5 of the pneumatic door and the communication module 7 .

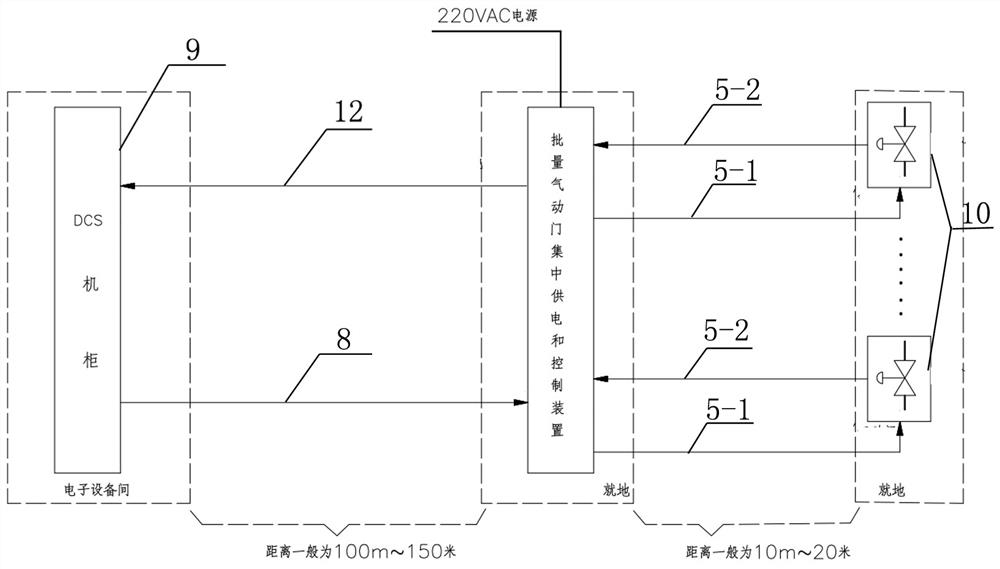

[0019] Such as figure 2 As shown in or 3, the device is powered by an external 220VAC power supply, and connects the DCS cabinet 9 and multiple pneumatic doors 10. On the one hand, it receives the DO control commands of multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com