Three-output-shaft clutch of washing machine

A clutch and three-output technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of large power consumption, secondary pollution, and the inability of washing machines to meet energy-saving requirements, and achieve low cost, convenient control, and small appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

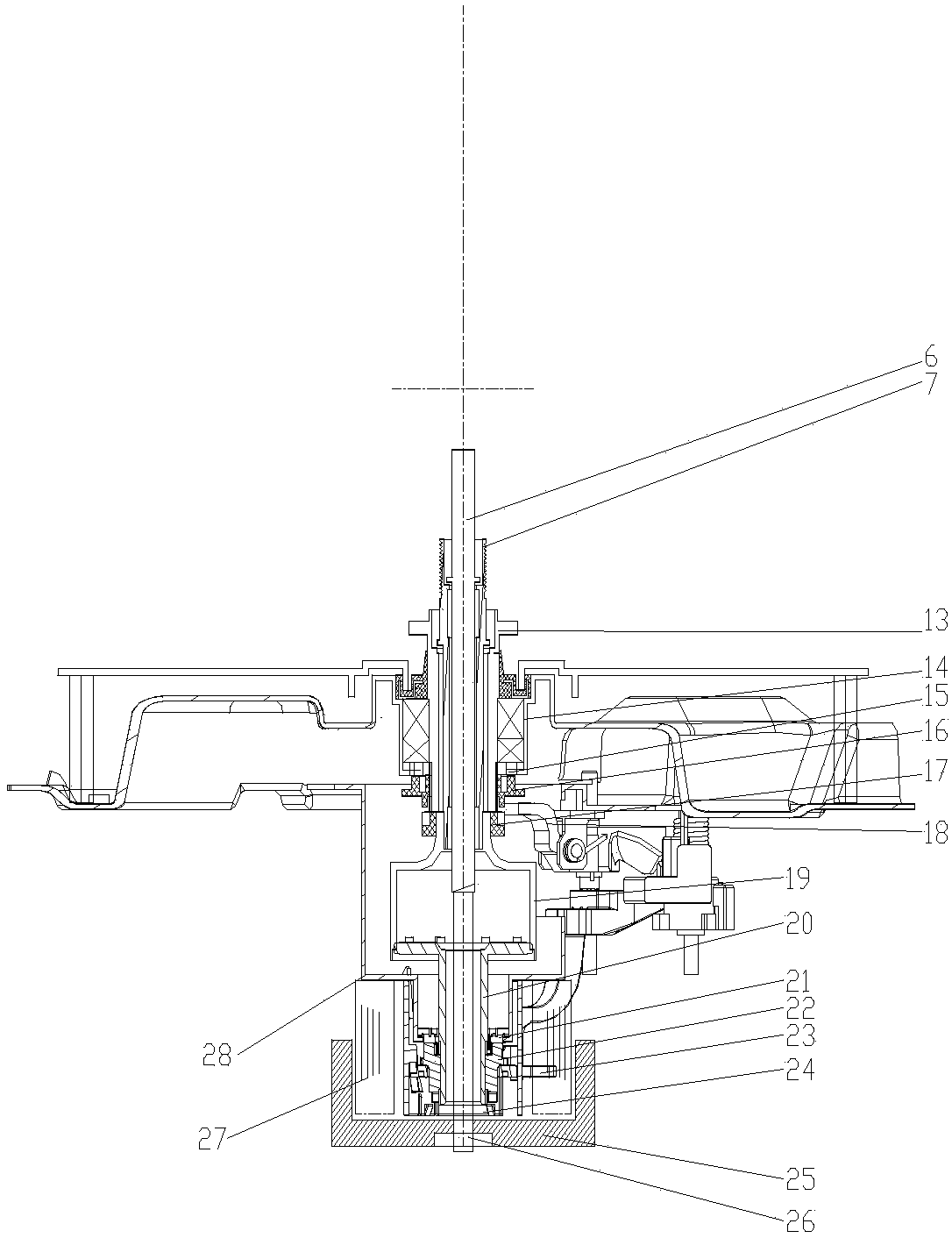

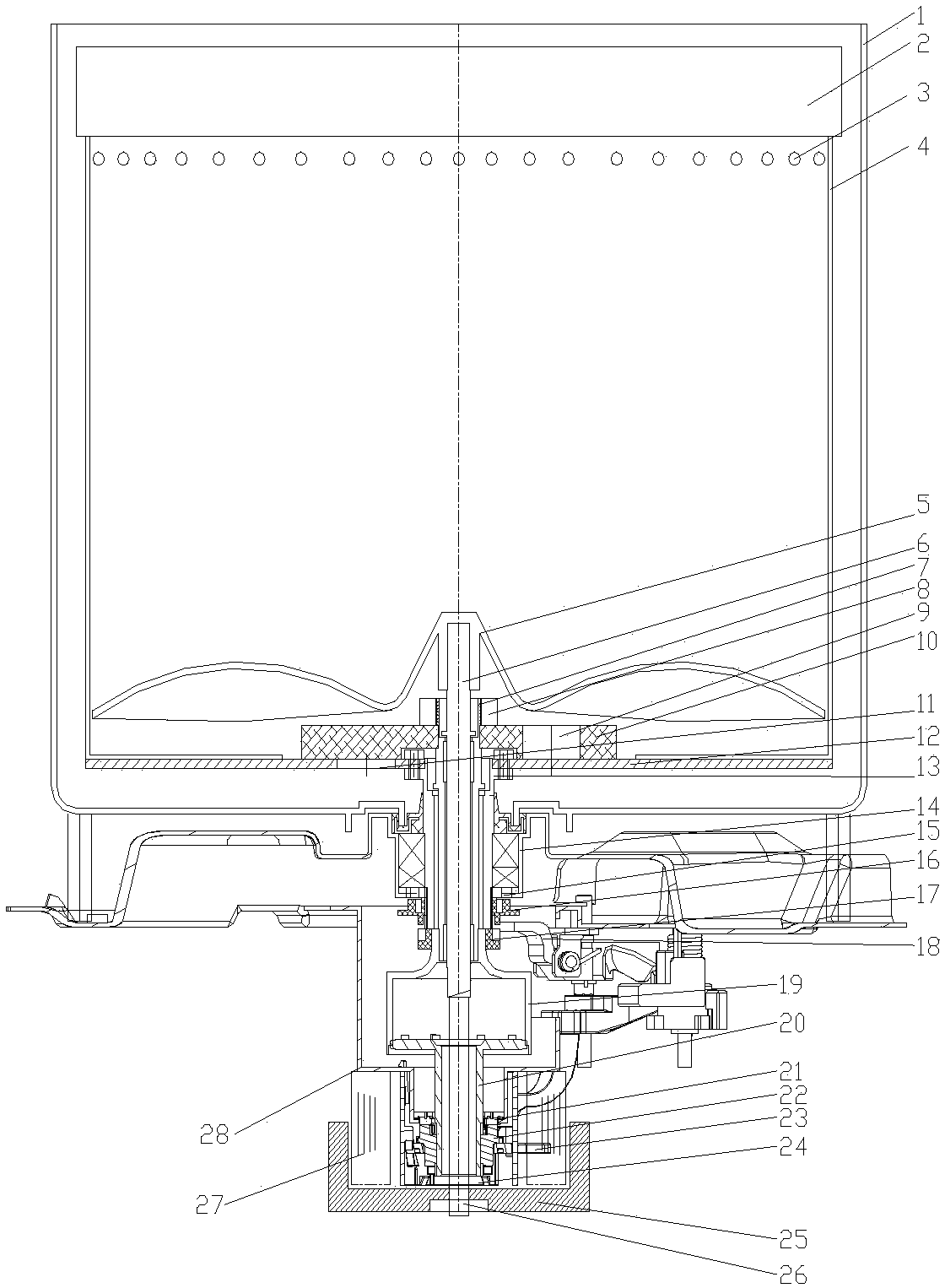

[0037] The output end of the three-output shaft clutch is set together by three shafts, including: the wave wheel shaft 6, the middle shaft sleeve 7 and the outer shaft sleeve 13. The three shafts are movably installed together through bearings and water seals, and can rotate freely in the circumferential direction. .

[0038] Wherein the lower end of the pulsator shaft 6 is connected with the inner planet carrier of the brake wheel 19, and the upper part is connected with the pulsator 5;

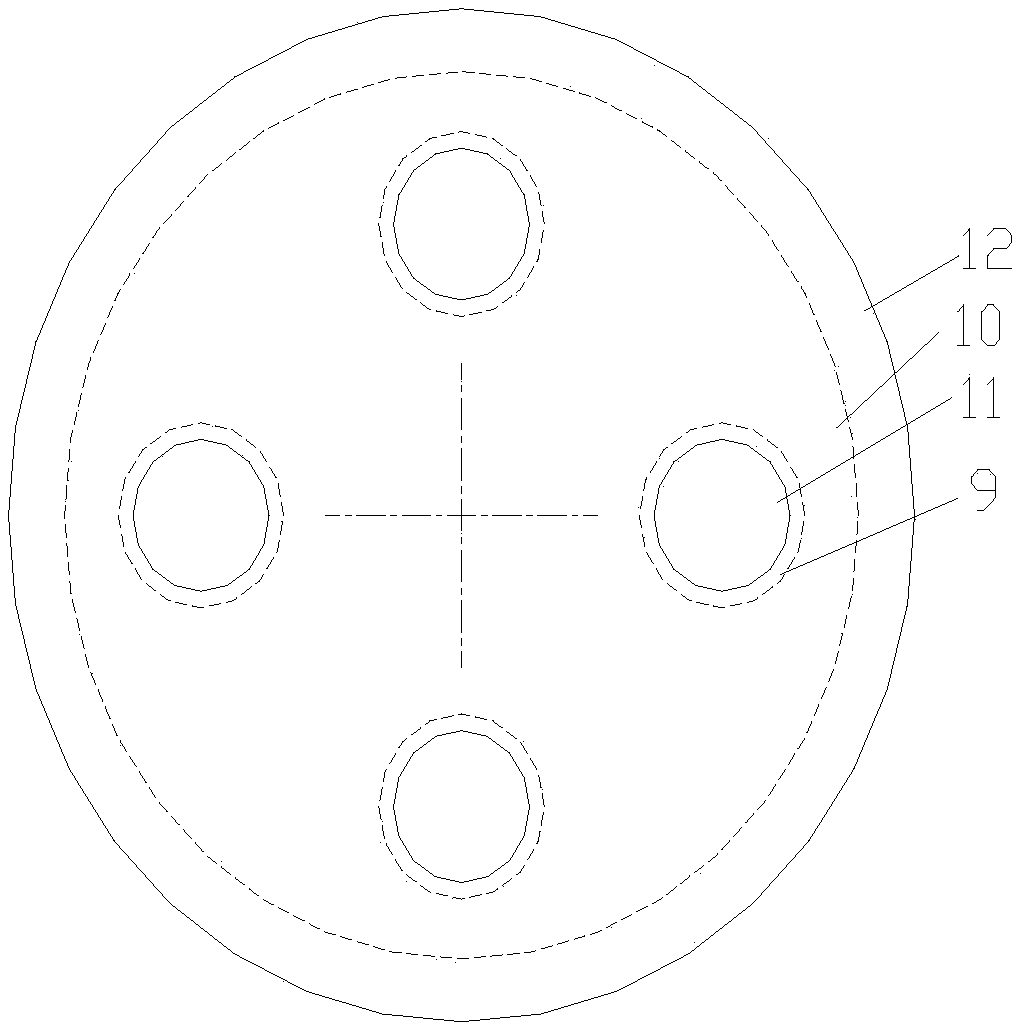

[0039] The lower end of the central shaft sleeve 7 is connected with the brake wheel 19, and the upper part is connected with a water sealing disc 10;

[0040] Outer axle sleeve 13 is the axle sleeve of empty sleeve at outermost end, is connected with washing tub flange 12 on it.

[0041] The outer shaft sleeve 13 is provided with a spline groove, and the upper clutch sleeve 16 is set on it, and the upper clutch sleeve 16 can slide axially. The two ends of the upper clutch sleeve 16 are re...

Embodiment 2

[0059] Embodiment 2. The three-output-shaft clutch of this mode is similar to the above-mentioned clutch, and the lower part is the same, only the top end of the central shaft sleeve 7 is a spiral structure, or a slope structure, and the middle part of the sealing water plate 10 is also a spiral structure, or is connected to the slope. In the structure corresponding to the structure, the water sealing plate is also provided with guide and limit pins. When the middle bushing 7 rotates through an angle relative to the outer bushing 13, the water sealing plate 10 cannot rotate due to the guide and limit pins. Under the control of the middle helical structure or slope structure, it can slide along the axial direction.

[0060] There is no drainage hole on the sealing water tray 10, when the sealing water tray 10 moves down, it will be pressed against the flange surface to block the flange drainage hole 11 on the flange 12, at this moment, the inside of the washing tub is closed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com