A kind of sound-absorbing microsphere material and preparation method thereof

A technology of microspheres and silane coupling agents, which is applied in the field of loudspeakers, can solve the problems of insufficient bonding effect of zeolite particles, and achieve the effects of improving sound absorption, improving adhesion, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

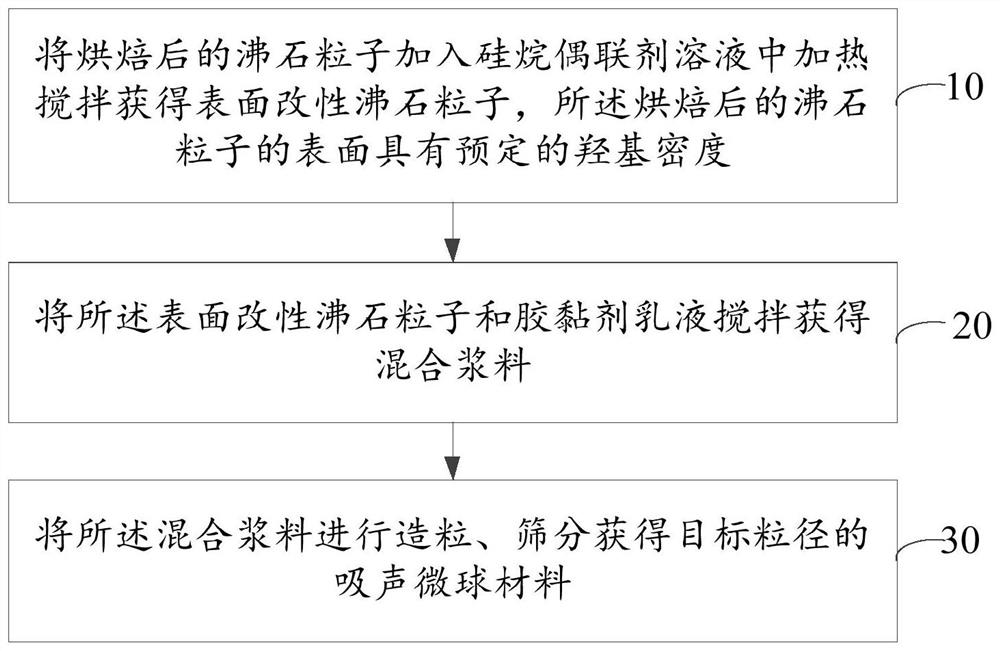

[0025] see figure 1 , figure 1 It is a schematic flow chart of a method for preparing a sound-absorbing microsphere material provided by an embodiment of the present invention, as figure 1 As shown, the method 100 includes:

[0026] Step 10, adding the baked zeolite particles into the silane coupling agent solution, heating and stirring to obtain surface-modified zeolite particles.

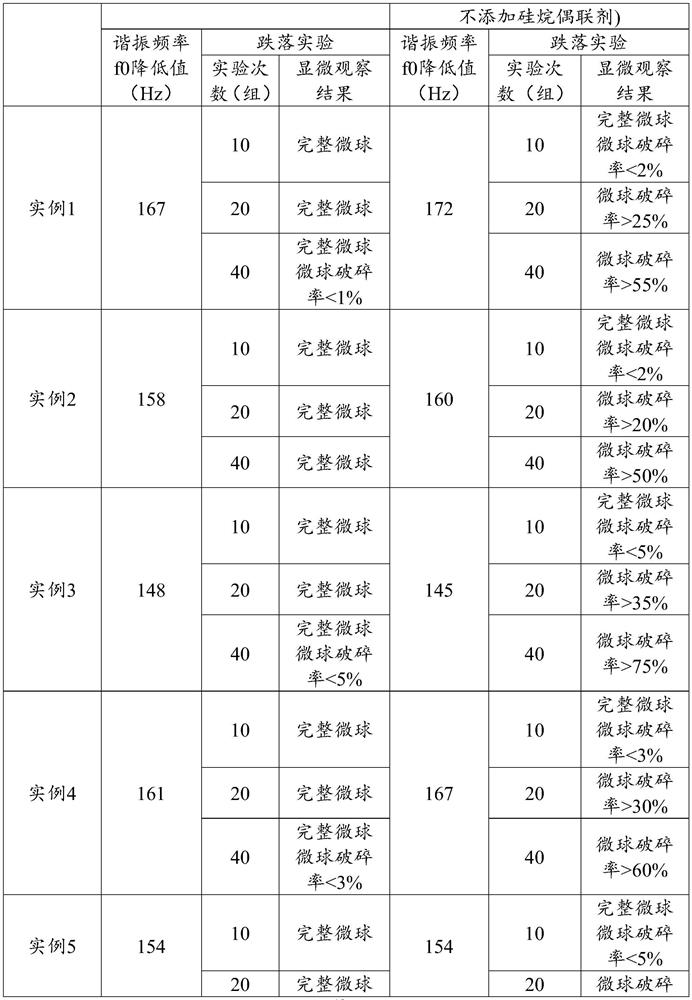

Embodiment 1

[0054] 1) Calcinate the dried zeolite raw material particles (the zeolite structure is FER, and the average pore diameter of micropores is about 0.49nm) at 800°C for 12h, and the hydroxyl density on the surface of the prepared zeolite particles is: 0.6-0.8OH / nm 2 .

[0055] 2) According to the mass ratio, weigh 90 parts of anhydrous methanol, 5 parts of deionized water and 5 parts of γ-(methacryloyloxy)propyltrimethoxy (KH570) and mix evenly, and mechanically stir at 1000rpm at room temperature for 1h , to hydrolyze part of the siloxane coupling agent.

[0056] 3) Add 30 parts of the calcined zeolite particles prepared in the above steps to the solution after hydrolyzing part of the siloxane coupling agent, and react with mechanical stirring at 1000 rpm for 3 hours in a constant temperature water bath at 50°C. The resulting solid was filtered, then ultrasonically washed with 150 parts of anhydrous methanol; after washing three times, it was dried at 120° C. for 4 hours to obt...

Embodiment 2

[0061] 1) Calcinate the dried zeolite raw material particles (the zeolite structure is FER, and the average pore diameter of micropores is about 0.49nm) at 700°C for 12h, and the hydroxyl density on the surface of the prepared zeolite particles is: 1.0-2.0OH / nm 2 .

[0062] 2) According to the mass ratio, weigh 90 parts of anhydrous methanol, 5 parts of deionized water and 5 parts of γ-aminopropyltriethoxy (KH550) and mix them evenly, and mechanically stir at 1000 rpm for 1 hour at room temperature to make part of the silica Hydrolysis of the coupling agent.

[0063] 3) Add 30 parts of the calcined zeolite particles prepared in the above steps to the solution after hydrolyzing part of the siloxane coupling agent, and react with mechanical stirring at 1500 rpm for 2 hours under the condition of a constant temperature water bath at 60°C. The obtained solid was filtered, and then ultrasonically washed with 150 parts of absolute ethanol; after washing three times, it was dried at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap