Method for increasing purity of extracted hesperidin and hesperidin

A technology of hesperidin and purity, which is applied in the field of hesperidin to improve the purity of hesperidin extraction, which can solve the problems of difficult purification, loss of hesperidin, high impurity content, etc., and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

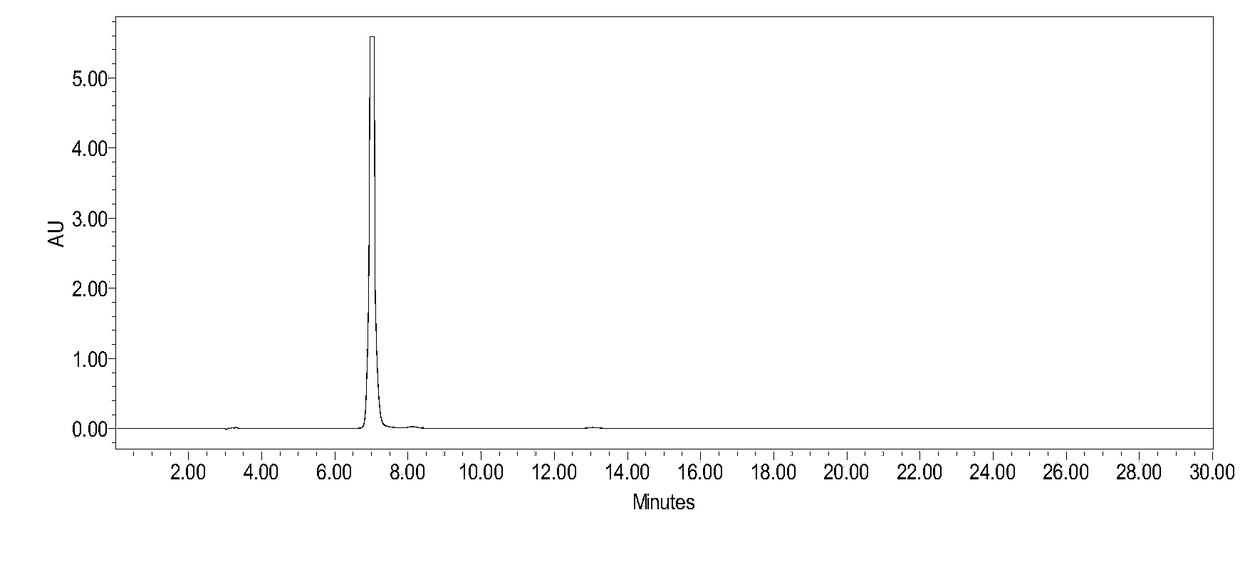

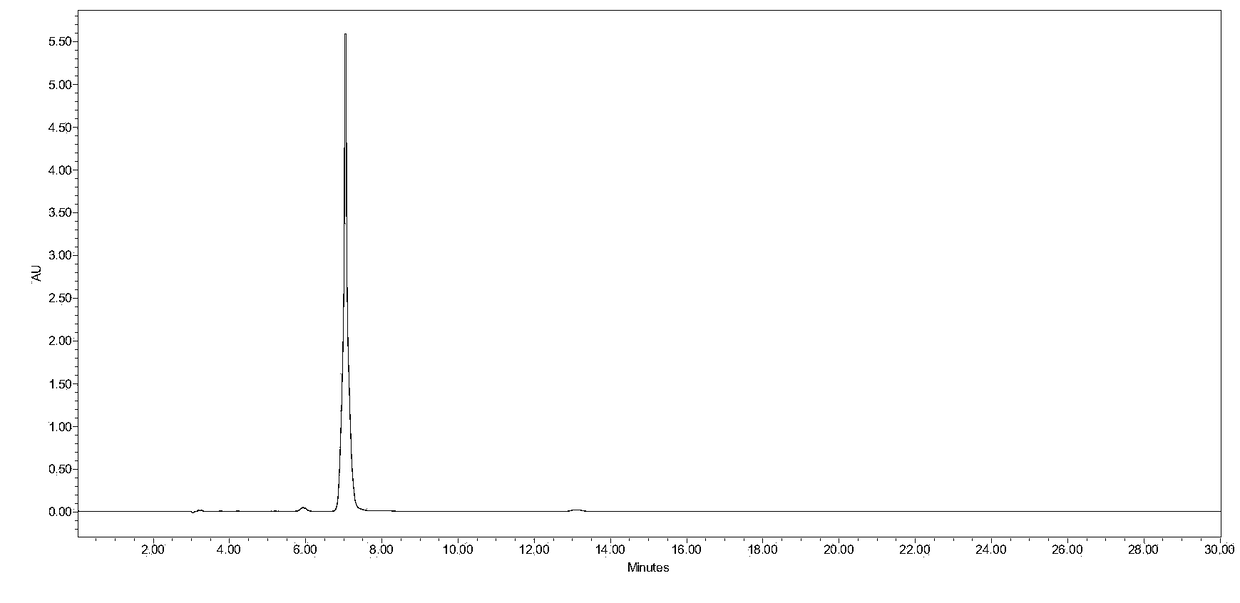

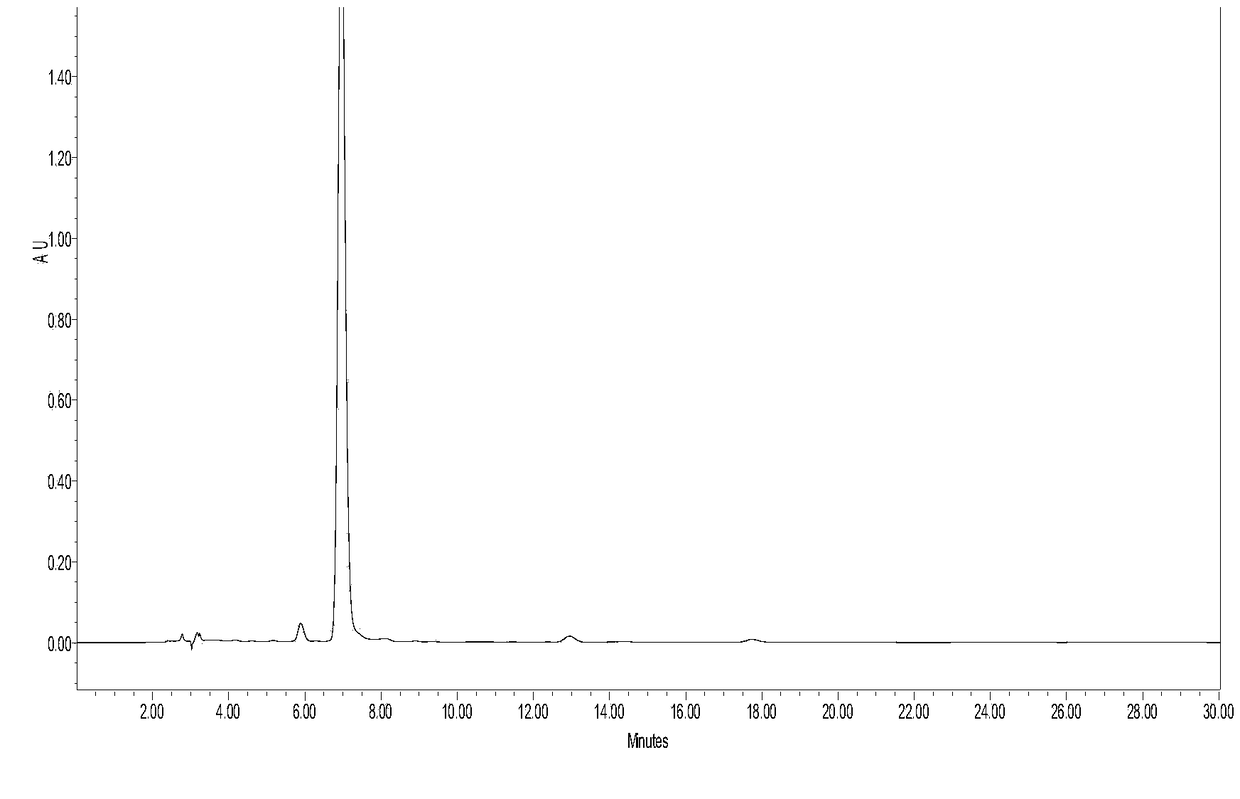

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for improving the purity of hesperidin extraction, comprising the following steps:

[0043] S1, remove impurities;

[0044] Take 100g Fructus Fructus Aurantii, pulverize Fructus Fructus Fructus Fructus Fructus Fructus Aurantii, after crushing Fructus Fructus Fructus Fructus Fructus Aurantii, pass 100 mesh sieves to obtain Fructus Fructus Fructus Fructus Aurantii coarse powder. Mix the coarse powder of Fructus Citrus Fructus with 100g of water to obtain the first mixture, and seal and soak it with a plastic wrap for 10 hours.

[0045] The first mixture was mixed with the sodium hydroxide solution, so that the pH of the mixture of the first mixture and the sodium hydroxide solution was 8, and the concentration of the sodium hydroxide solution was 0.12 mol / L.

[0046] The soaking time is 1 hour. After the soaking is completed, filter to remove the filtered mother liquor and collect the filtered residue.

[0047] S2, initial extraction; ...

Embodiment 2-3

[0056] Embodiment 2-3 provides a method for improving the purity of hesperidin extraction, and the basic operation of embodiment 2-4 is the same as that of embodiment 1, the difference is that the operating conditions change.

Embodiment 2

[0058] S1, remove impurities;

[0059] Fructus Fructus Aurantii is pulverized and passed through an 80-mesh sieve, mixed with water, the water is 120g, and the soaking time is 8 hours. The alkaline substance used is potassium hydroxide, the concentration is 0.12mol / L, and the pH value is 8.5. After adjusting the pH value, soak for 1.2 hours.

[0060] S2, initial extraction;

[0061] The lye used is potassium hydroxide, the concentration is 1mol / L, the pH value is 12, the soaking time is 2.5 hours, the concentrated hydrochloric acid is used to adjust the pH value to 3.5, and the standing time of the first extraction filtrate is 12 hours. The centrifugation speed is 4000r / min, and the centrifugation time is 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com