Lamp cup carrying trolley

A technology for carrying trolleys and light cups, applied to motor vehicles, trolleys, trolley accessories, etc., can solve the problems of high labor intensity, failure to maintain, waste, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

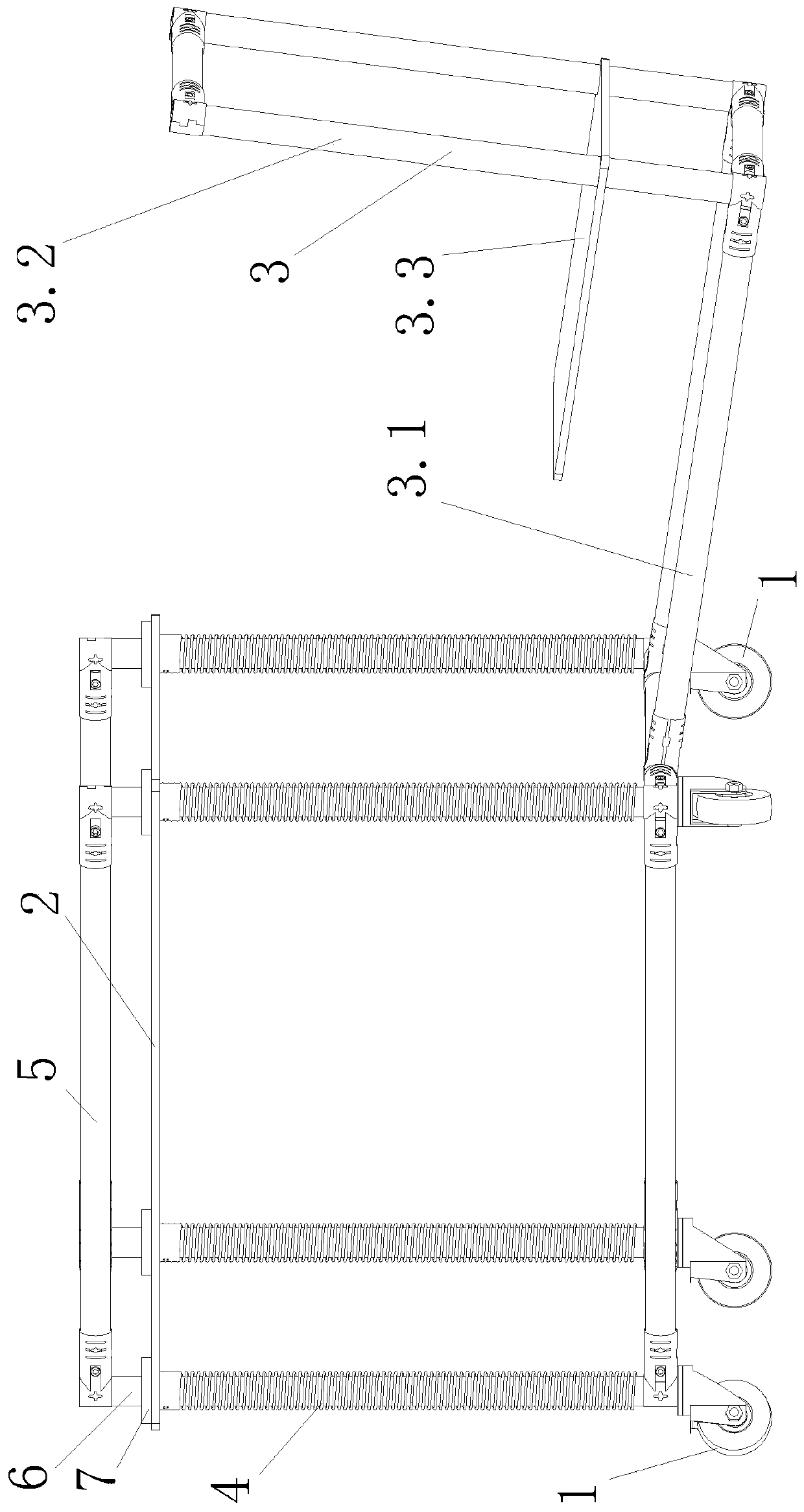

[0020] Such as figure 1 As shown, the present invention includes a wheel 1 arranged under the wheel mounting frame, and a light cup frame placing plate 2 . Wherein, the mounting brackets of the two wheels on the left side under the wheel mounting frame [this embodiment is a rectangular frame body] are fixedly connected with the wheel mounting frame, and the mounting brackets of the two wheels on the right side under the wheel mounting frame are installed with the wheel. Rack swivel connection. In addition, it also includes a blister placing frame 3, a spring 4, a protective frame 5, a protective frame support column 6 and a flange bearing 7. The upper end of the protective frame support column 6 is connected with the protective frame 5, and the lower end of the protective frame support column 6 passes through the lamp cup frame placing plate 2 and the spring 4 in turn and is connected with the wheel mounting frame. Preferably, four flange bearings 7 are respectively arranged...

Embodiment 2

[0025]The difference between the second embodiment and the first embodiment is that in the first embodiment, the angle of inclination of the lower frame 3.1 of the placing frame is adjusted and then fixed with a bolt structure. And in embodiment two, instead of utilizing bolts to fix, but using two universal wheel brackets, the leftmost end of the lower frame of the placement frame is hinged with the right end of the wheel mounting frame, and the upper ends of the two universal wheel brackets are respectively connected to the bottom of the placement frame. The middle parts of the front and rear frame rods of the frame are adjustable and connected by a rack and pinion structure, and the universal wheels on the universal wheel bracket are supported on the ground. After adjustment, just lock the rack and pinion structure. The specific structural details will not be described here. repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com