Duplex planetary gear train torque directional distribution electric drive axle

A double planetary, electric drive technology, applied in the direction of electric power unit, wheel, power unit, etc., can solve the problem of equal output torque and inability to adjust the differential, achieve small axial size, small space occupation, and improve driving. fun effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

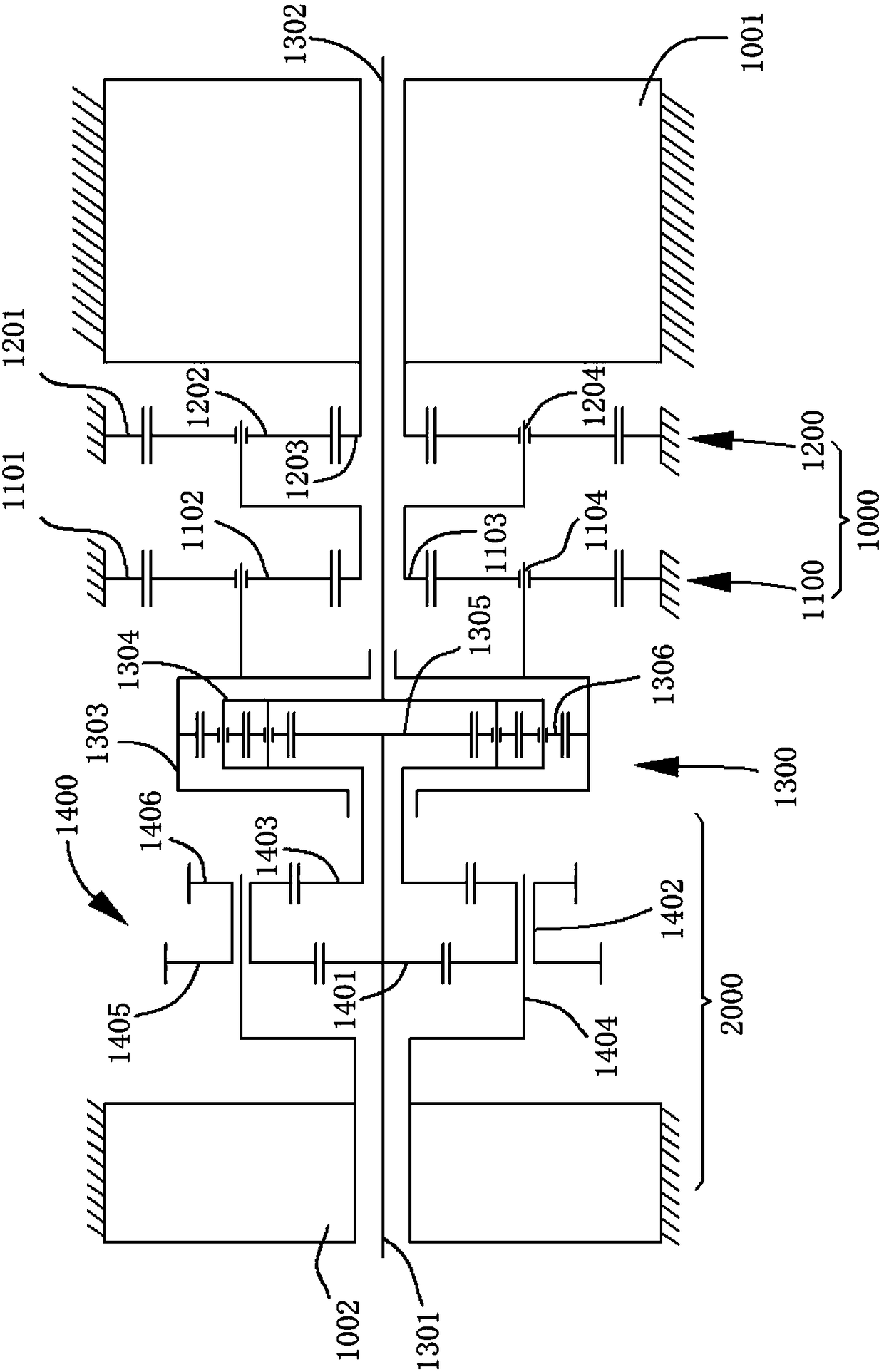

[0039] Such as figure 1As shown, the present invention provides a dual planetary gear train torque directional distribution electric drive axle, which mainly consists of a torque directional distributor 2000, a two-stage planetary wheel planetary differential 1300, a main drive mechanism (including a reduction mechanism 1000 and Main drive motor 1001) constitutes.

[0040] The torque directional distributor 2000 is located on the left side of the driving axle (it can also be exchanged with the main driving mechanism composed of the main driving motor 1001 and the final reduction mechanism 1000, and it is arranged on the right side of the driving axle), and the driving mechanism is mainly controlled by the TV (Here is TV control drive motor 1002), double planetary gear planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com