Automatic correcting device for filter resistor frame

An automatic correction and filter technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy deviation, high labor intensity, rework, etc., to avoid rework, avoid labor intensity enhancement, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

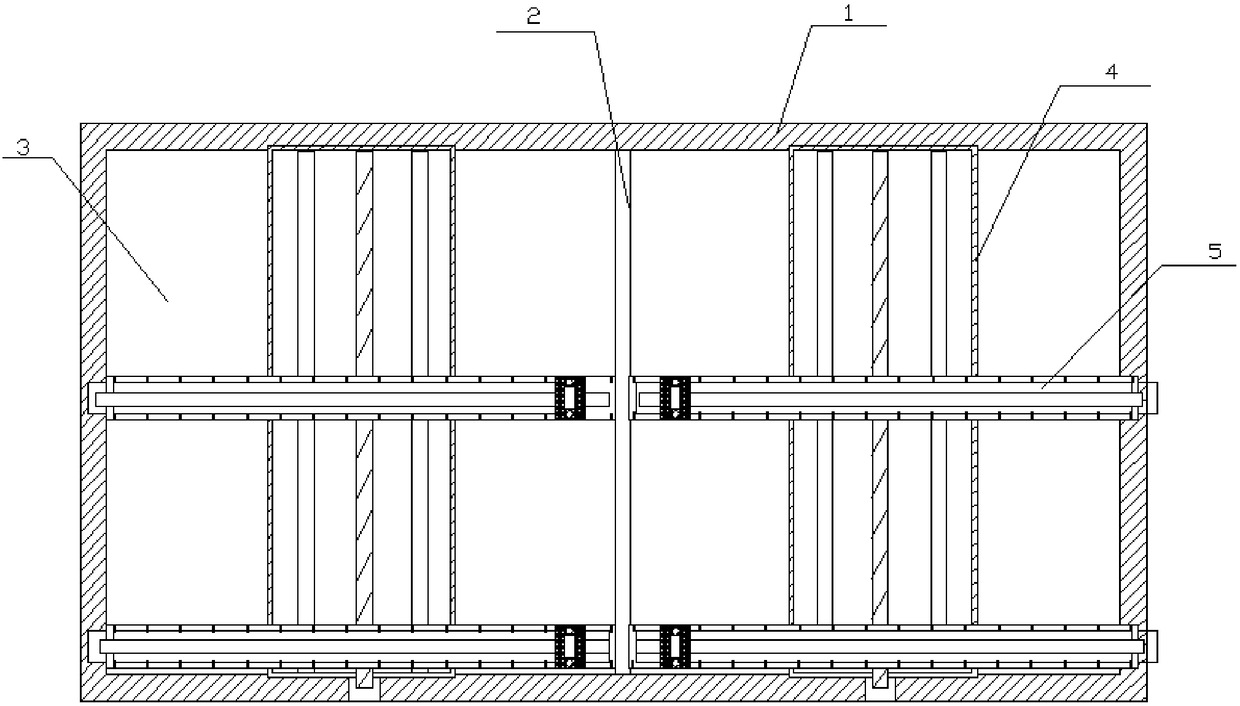

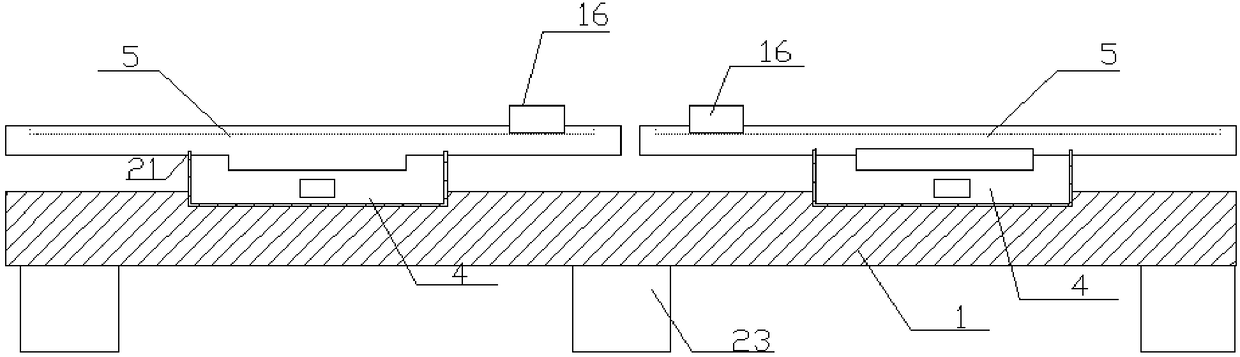

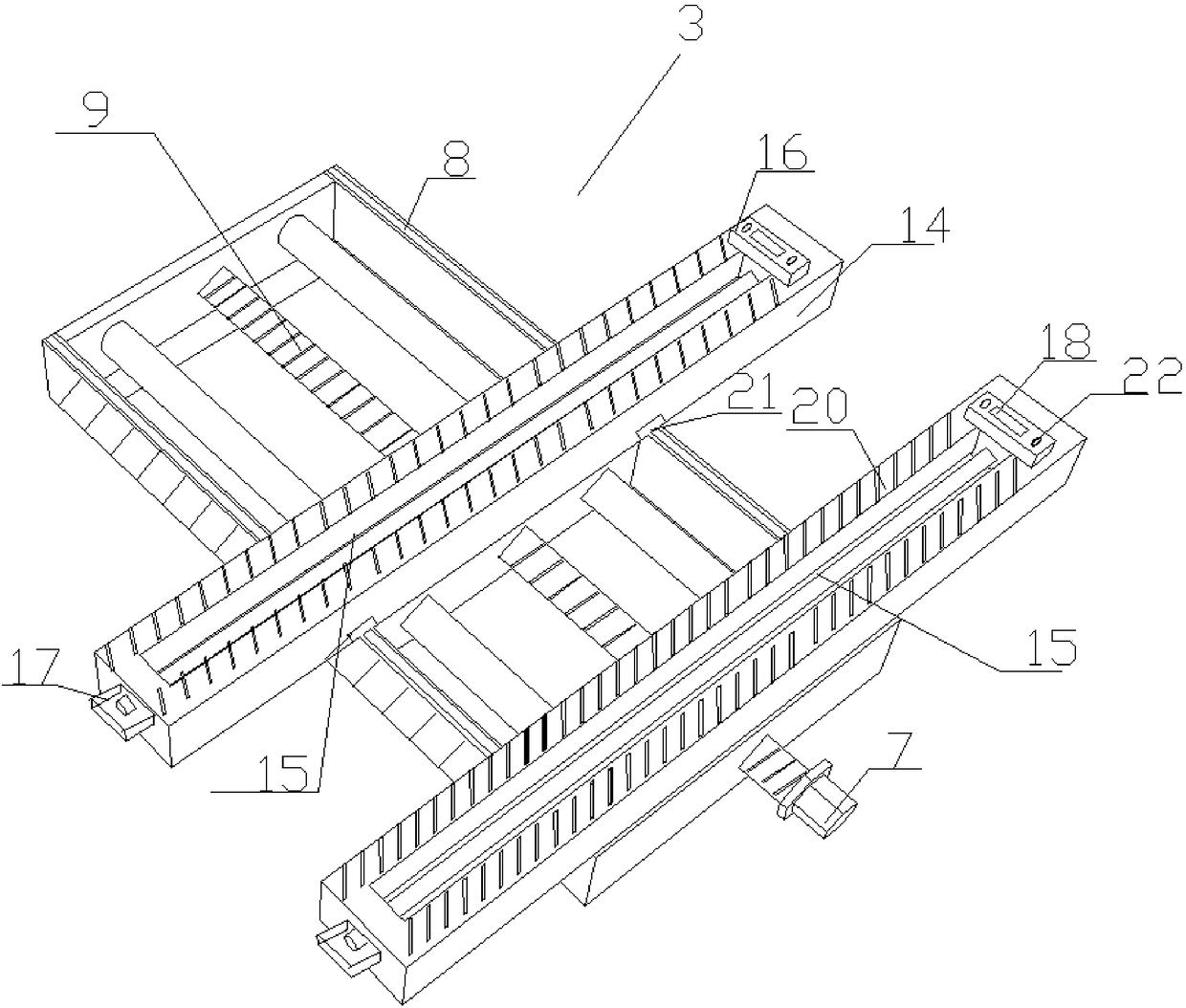

[0025] The technical scheme adopted by the present invention is as follows: an automatic correction device for a filter resistor frame, comprising a rectangular underframe 1, a transverse strut 2 is arranged at the middle of the rectangular underframe 1, and the two sides of the transverse strut 2 The automatic correction assembly 3 that is fixedly connected with the rectangular chassis 1 is arranged symmetrically, each of the automatic correction assemblies 3 includes a horizontal assembly 4 and two horizontal assemblies 5, and the two ends of the horizontal assembly 4 are respectively connected to the rectangular chassis 1 Corresponding sides are fixedly connected, one end of each horizontal component 5 extends to the transverse strut 2, and the other end of each horizontal component 5 extends to one side of the rectangular underframe 1, the transverse component 4 includes a horizontal screw rod 9 slide rail 6 and a first driving device 7, and the horizontal screw rod 9 slide...

Embodiment 2

[0028] On the basis of Embodiment 1, horizontal scale lines 19 are uniformly arranged on the side of the horizontal base 8 of the horizontal assembly 4 ; horizontal scale lines 20 are uniformly arranged on the side of the horizontal base 14 . By adopting the horizontal scale line 19 and the horizontal scale line 20, the automatic calibration device can be adjusted more accurately, which saves time and improves efficiency.

Embodiment 3

[0030] On the basis of Embodiment 1, the horizontal base 14 provided on the sliding block 11 is provided with a groove 21 which is slidably connected with the transverse base 8 . By adopting the groove 21, the horizontal base 14 slides along the side wall of the transverse base 8, so that the derailment of the horizontal base 14 is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com