Exhausting spill-proof noise-reducing cup cover and high speed blender

A cup lid, noise reduction technology, applied in the direction of preventing overflow, cooking utensils, household utensils, etc., can solve the problems of overflow, affecting the operator's experience, spray and bubble spray, etc., to prevent overflow, simple structure and manufacturing process , the effect of eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

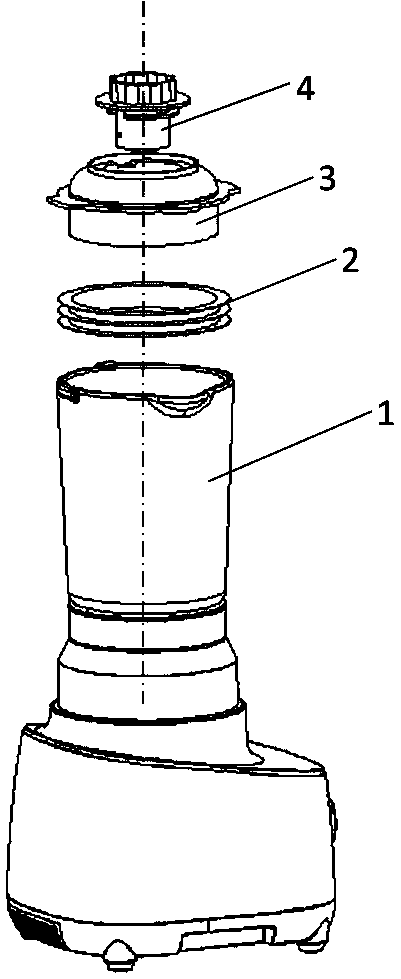

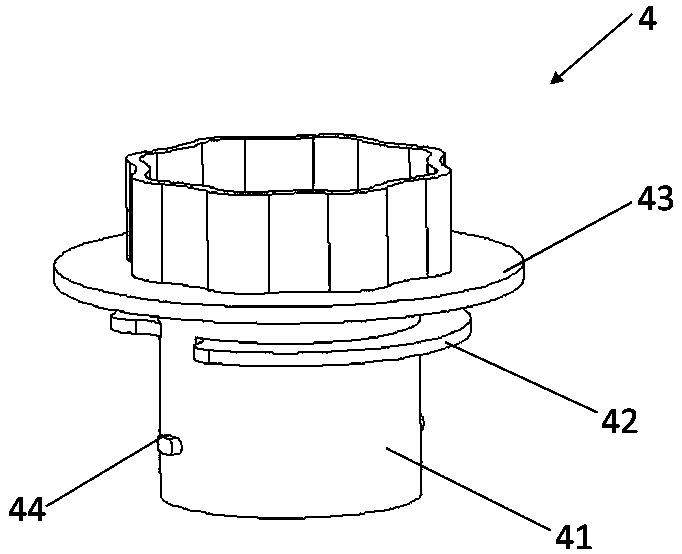

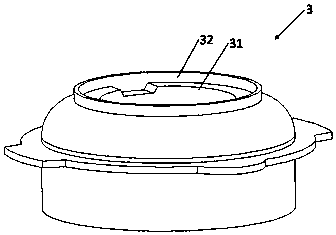

[0048] Such as Figure 1~10 As shown, a kind of exhaust anti-overflow noise reduction cup cover includes a cup body 1, a cup cover 3 is provided on the upper open end of the cup body 1, a feeding cover 4 is arranged in the cup cover 3, and the cup The inner side of the cover 3 and the outer side of the feeding cover 4 are combined to form a first annular cavity 5 and a second annular cavity 6 for noise reduction and exhaust communicating with each other. The first annular cavity 5 communicates with the feeding cover 4 through the inner exhaust hole 7 , the second annular cavity 6 communicates with the outside through the second exhaust channel 9 for preventing overflow and breaking bubbles.

[0049] An inner cavity is formed in the feeding cover 4, and noise and water bubbles in the inner cavity bounce back against the inner cylinder wall to reduce noise and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com