Modular vegetation used for roof greening

A roof greening and modular technology, applied in botany equipment and methods, horticulture, container cultivation, etc., can solve the problems of high cost of roof greening maintenance, load-bearing and waterproof problems, and difficulty in ensuring long-term growth of plants, etc., to reduce labor costs Maintenance cost, meet the needs of plant growth, and reduce the effect of irrigation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Lawn planting test, the specific method is as follows:

[0039] (1) Lay plastic drainage and water storage modules on the concrete surface, the thickness of the plastic modules is 2cm, the length is 42.5cm, and the square structure module with a width of 42.5cm;

[0040] (2) Lay a glass pumice layer on the plastic module, the thickness of the glass pumice layer is 2cm, and the particle diameter of the glass pumice is 0.5-1cm;

[0041] (3) Laying the thickness of the regenerated root matrix layer is 1cm (thermoplastic cotton felt), and the regenerated root matrix layer is made up of the following raw materials in weight percentage: polypropylene staple fiber 30%, cotton 40%, aramid fiber 30%;

[0042] (4) Spread slow-release fertilizer evenly;

[0043] (5) Lay the lawn.

[0044] The plastic module and glass pumice are the main components of the drainage and storage layer. The glass pumice is laid in the plastic module and tightly combined, which can not only quickly re...

Embodiment 2

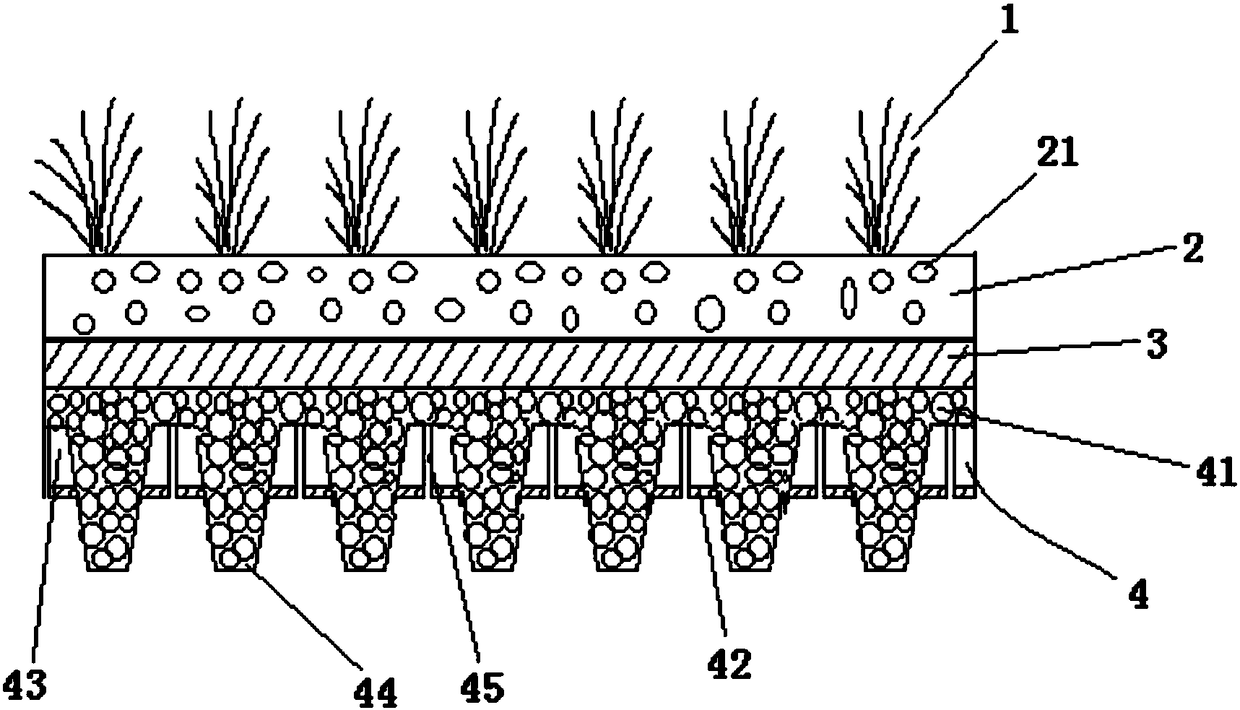

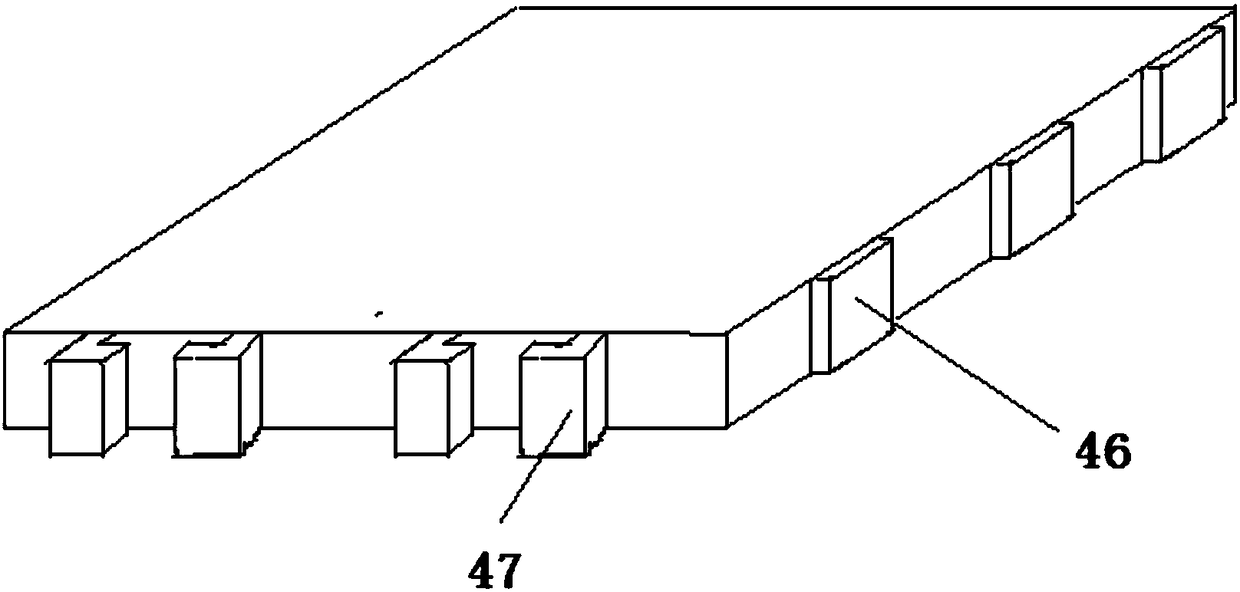

[0048] A modular vegetation for roof greening, the greening lawn is composed of multiple modular lawns, and the structure of each modular lawn is as follows figure 1 Shown, comprise lawn 1, planting soil layer 2, regenerated root matrix layer 3 and plastic module 4 successively from top to bottom, plastic module 4 comprises plastic basket and the glass pumice layer 41 that is laid in plastic basket inside, the bottom plate of plastic basket 42 is provided with evenly arranged frustum-shaped projections 43 and inverted frustum-shaped grooves 44 , the bottom of the grooves 44 is closed, and the top of the projections 43 is provided with a drainage hole 45 .

[0049] Groove 44 is set so that the plastic basket has a larger water storage capacity to ensure that the lawn has sufficient water source; protrusion 43 is set, and drainage hole 45 is provided at the top of protrusion 43, which can effectively discharge excess water and avoid The root system of the lawn is soaked in water...

Embodiment 3

[0061] Adopt the modular plant of the same structure as embodiment 2, the difference is:

[0062] (1) The particle diameter of the slow-release fertilizer is 1.5mm;

[0063] (2) The composition of the regenerated root matrix layer is: polypropylene fiber 20%, cotton 30%, aramid fiber 50%;

[0064] (3) the thickness of glass pumice layer is 1.5cm, and the particle diameter of glass pumice is 0.5cm;

[0065] (4) The depth of the bottom plate of the plastic basket is 3cm;

[0066] (5) The depth of the groove from the bottom plate is 1cm;

[0067] (6) The plants used in this embodiment are shrubs.

[0068] After about two months, the shrub, rooting substrate layer, and glass pumice layer are tightly combined, fully modular, and the shrub is growing well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com