Cart for pasture bare land forage grass sowing

A small trolley and forage technology, applied to shovels, plows, agricultural machinery and implements, etc., can solve problems such as long time spent, uneven sowing, slow sowing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

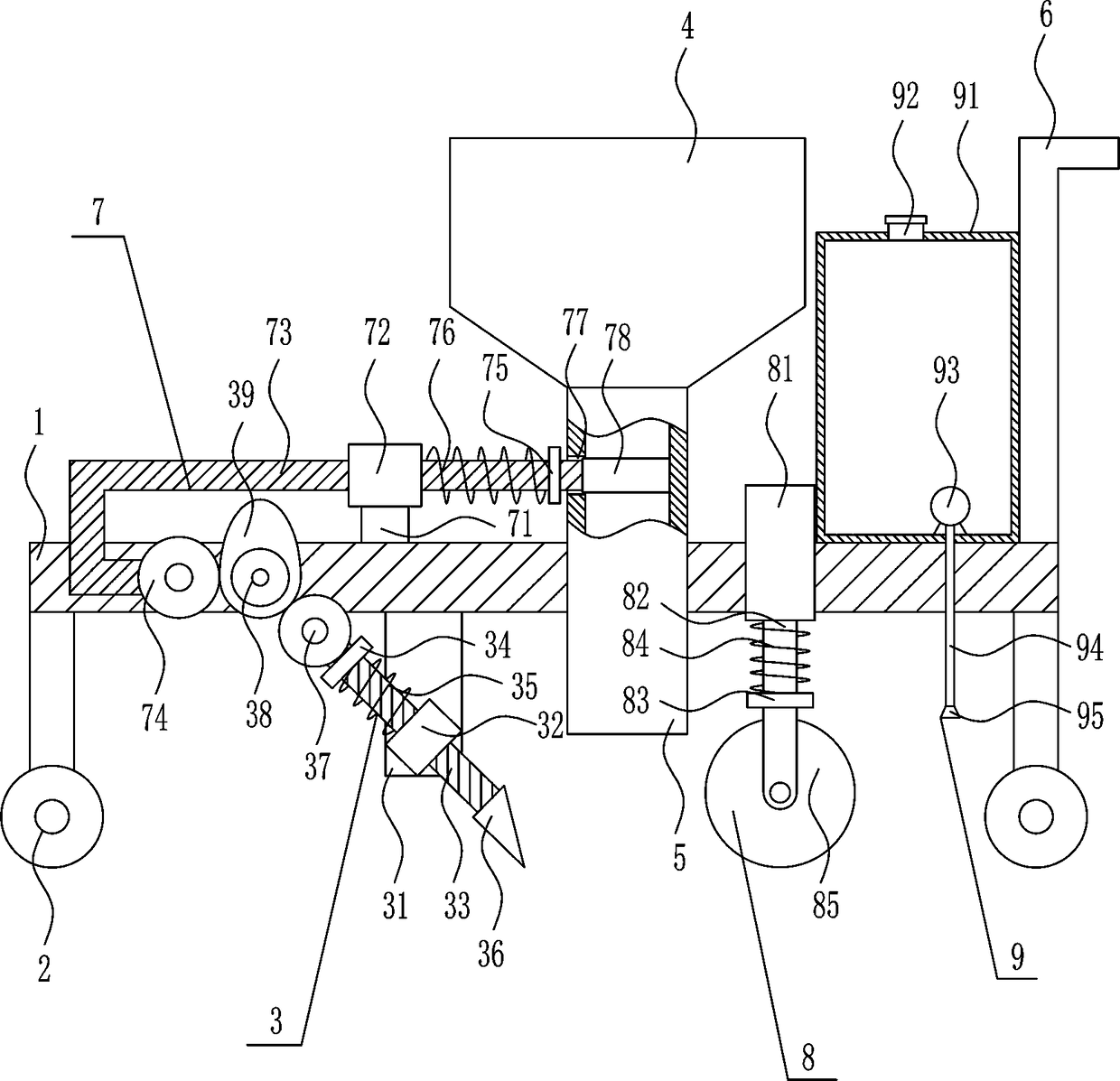

[0029] A kind of small trolley for pasture sowing in pasture bald land, such as Figure 1-3 As shown, there are base plate 1, wheel 2, shovel mechanism 3, funnel 4, discharge pipe 5, push handle 6 and seeding mechanism 7, the bottom of base plate 1 is provided with wheel 2, and shovel mechanism 3 is installed on the base plate 1, the base plate A funnel 4 is arranged in the middle of the top, a discharge pipe 5 is arranged at the bottom of the funnel 4, a push handle 6 is arranged on the right side of the top of the bottom plate 1, and a seeding mechanism 7 is installed on the bottom plate 1.

Embodiment 2

[0031] A kind of small trolley for pasture sowing in pasture bald land, such as Figure 1-3 As shown, there are base plate 1, wheel 2, shovel mechanism 3, funnel 4, discharge pipe 5, push handle 6 and seeding mechanism 7, the bottom of base plate 1 is provided with wheel 2, and shovel mechanism 3 is installed on the base plate 1, the base plate A funnel 4 is arranged in the middle of the top, a discharge pipe 5 is arranged at the bottom of the funnel 4, a push handle 6 is arranged on the right side of the top of the bottom plate 1, and a seeding mechanism 7 is installed on the bottom plate 1.

[0032]The shoveling mechanism 3 includes a first fixed plate 31, a first sliding sleeve 32, a first slide bar 33, a first spring seat 34, a first return spring 35, a shoveling plate 36, a first contact wheel 37, a motor 38 and The cam 39 is vertically connected with the first fixed plate 31 at the middle left position of the bottom of the bottom plate 1, the front side of the first fixe...

Embodiment 3

[0034] A kind of small trolley for pasture sowing in pasture bald land, such as Figure 1-3 As shown, there are base plate 1, wheel 2, shovel mechanism 3, funnel 4, discharge pipe 5, push handle 6 and seeding mechanism 7, the bottom of base plate 1 is provided with wheel 2, and shovel mechanism 3 is installed on the base plate 1, the base plate A funnel 4 is arranged in the middle of the top, a discharge pipe 5 is arranged at the bottom of the funnel 4, a push handle 6 is arranged on the right side of the top of the bottom plate 1, and a seeding mechanism 7 is installed on the bottom plate 1.

[0035] The shoveling mechanism 3 includes a first fixed plate 31, a first sliding sleeve 32, a first slide bar 33, a first spring seat 34, a first return spring 35, a shoveling plate 36, a first contact wheel 37, a motor 38 and The cam 39 is vertically connected with the first fixed plate 31 at the middle left position of the bottom of the bottom plate 1, the front side of the first fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com