Frequency adjustment method of frequency converter of dust removal fan in tobacco leaf production line

A dust removal fan and production line technology, applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of high power, huge energy consumption of dust removal, and large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

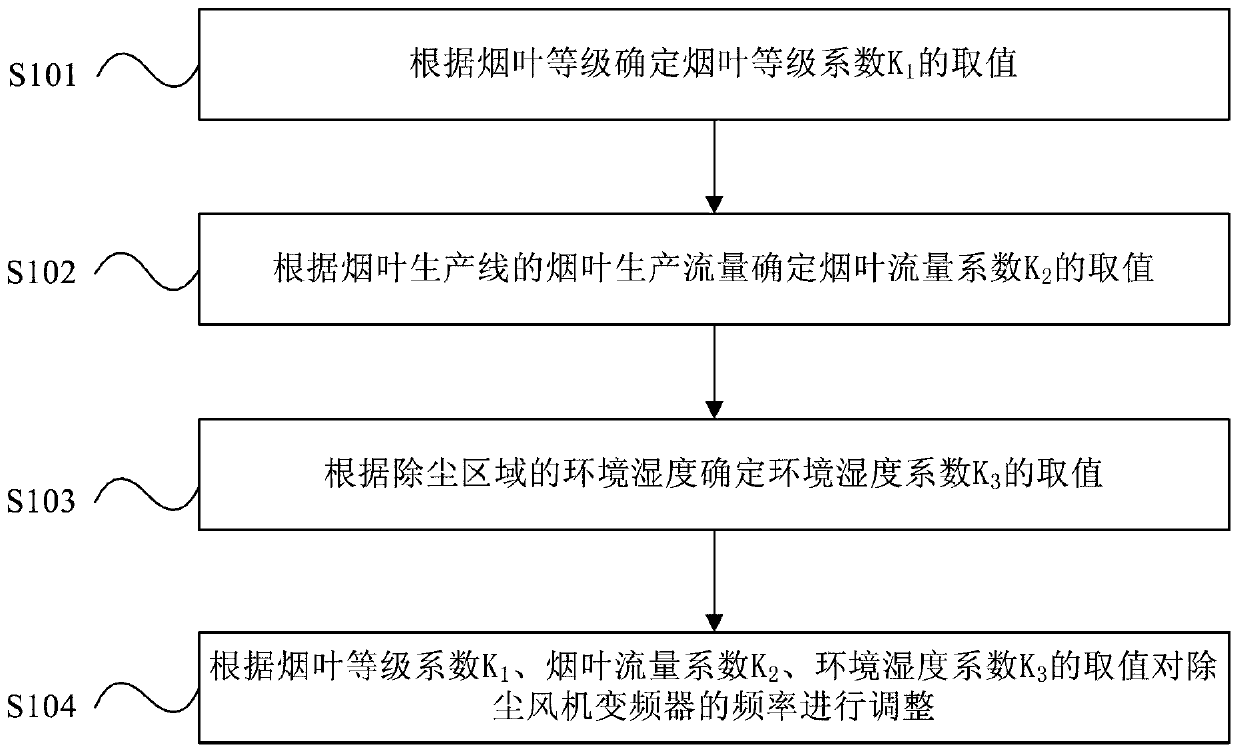

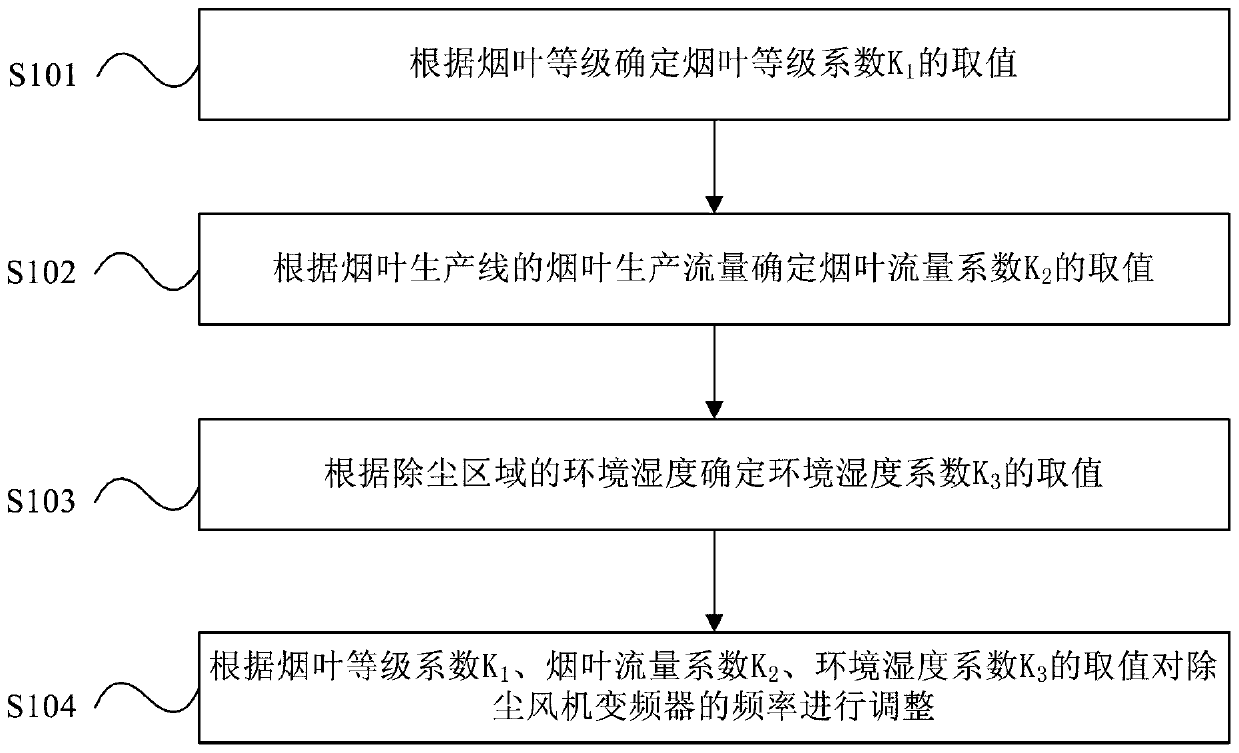

Method used

Image

Examples

Embodiment 1

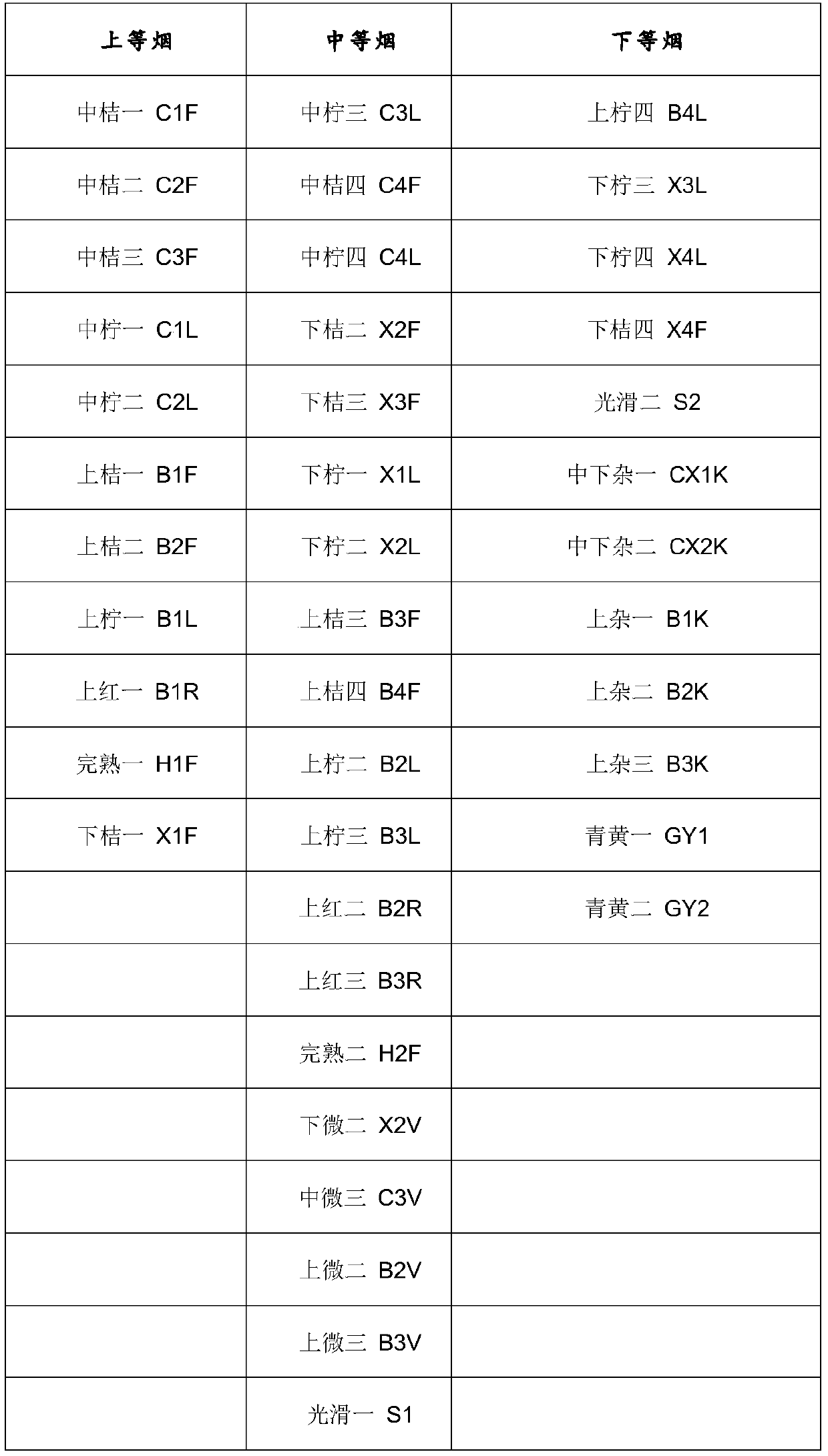

[0047] Embodiment 1: If the tobacco leaf currently produced is B1F, the flow rate of the production line is 6000kg / h, and the ambient humidity is 60%. At this time K 1 = 0.7 (upper smoke), K 2 =0.8(4000kg / h≦Flow≦8000Kg / h), K 3 =0.9 (70%≧humidity≧50%).

[0048] Inverter fan setting frequency = K 1 *K 2 *K 3 *50HZ=0.7*0.8*0.9*50HZ=25.2HZ,

[0049] At this time, the inverter outputs light load.

Embodiment 2

[0050] Embodiment 2: For the tobacco leaf X3L currently produced, the flow rate of the production line is 12000 kg / h, and the ambient humidity is 45%. At this time K 1 = 1.0 (lower smoke), K 2 =1.0 (greater than 8000Kg / h), K 3 =1.0 (when the humidity is less than 50% K 3 = 1.0).

[0051] Inverter fan setting frequency = K 1 *K 2 *K 3 *50HZ=1.0*1.0*1.0*50HZ=50HZ,

[0052] At this time, the frequency converter outputs at full load.

[0053] Remarks: When the tobacco leaf flow rate is 0kg / h, that is, when the production line is running empty, the control system will stop the operation of the environmental dust removal air by delaying the shutdown for a certain period of time.

[0054] The frequency adjustment method of the frequency converter of the dust removal fan in the tobacco leaf production line provided by the embodiment of the present invention is based on the preset value set for different tobacco leaf grades, tobacco leaf flow rates, and environmental humidity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com