Preparation method of bulletproof fabric

A fabric and veil technology, applied in viscose-made rayon, textiles and papermaking, weft knitting, etc., can solve problems such as damage, improve electrical conductivity, improve filtration speed, and improve fire and flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of bulletproof fabric, comprises the steps:

[0039] Step 1: The bottom yarn is made of high-strength fiber yarn, and the veil is made of flame-retardant materials, and then the bottom yarn and veil are woven into gray cloth through a large circular knitting machine;

[0040] Step 2: Pass the gray cloth through the raising machine to raise the veil;

[0041] Step 3: Shake the gray cloth through the shaker;

[0042] Step 4: The gray cloth is shaped by a shaping machine to obtain a finished product.

Embodiment 2

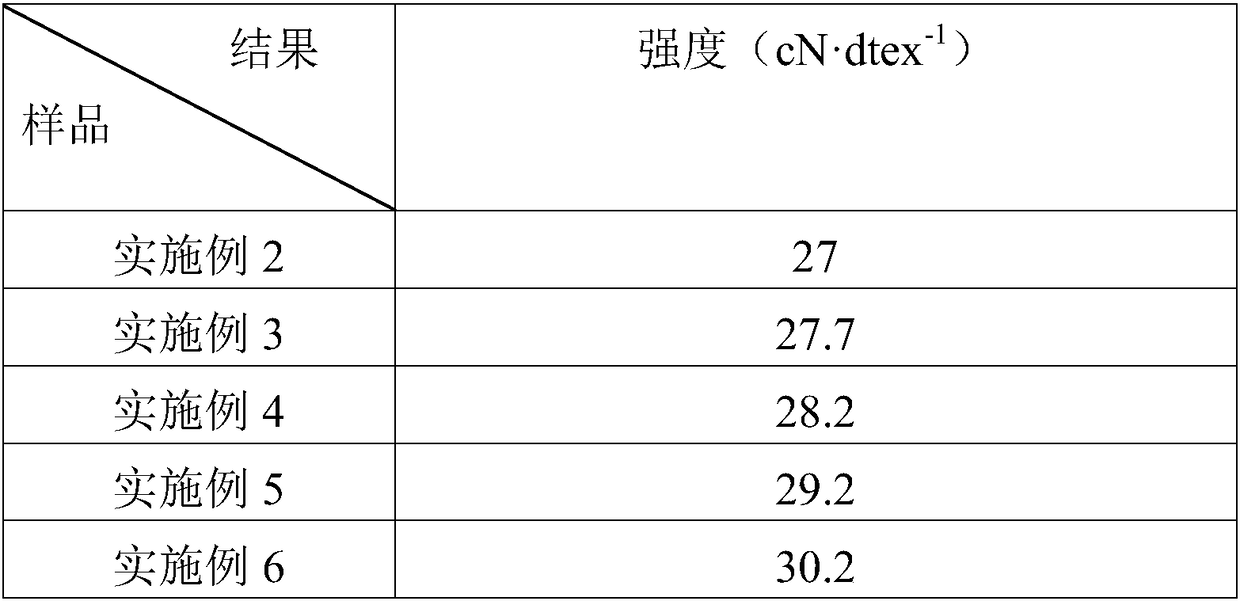

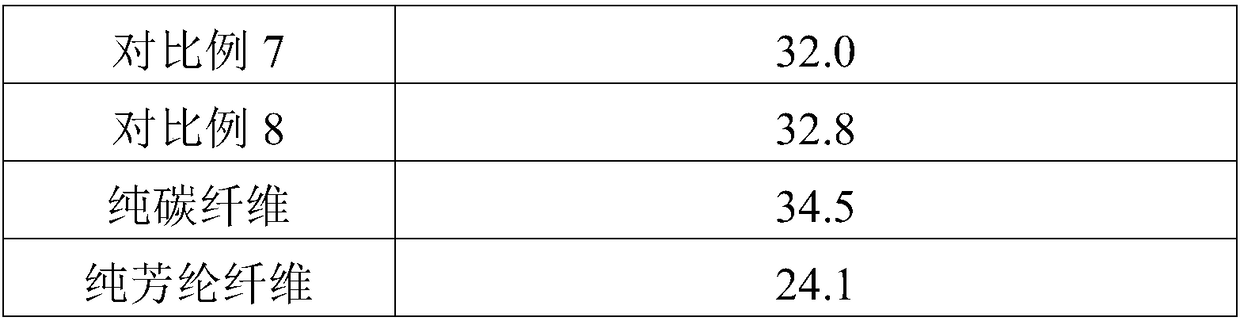

[0043] Example 2: The difference between Example 2 and Example 1 is that the high-strength fiber yarn in the bottom yarn is blended with carbon fiber filaments and aramid filaments, wherein the weight ratio of carbon fiber filaments is 30%, and aramid fibers The weight proportion of filaments is 70%.

Embodiment 3

[0044] Embodiment 3: The difference between embodiment 3 and embodiment 2 is that the weight ratio of carbon fiber filaments is 40%, and the weight ratio of aramid filaments is 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com