Hybrid-polarity InGaN solar cell structure

A technology of solar cells and mixed polarity, which is applied in the field of solar cells and can solve problems such as low efficiency of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

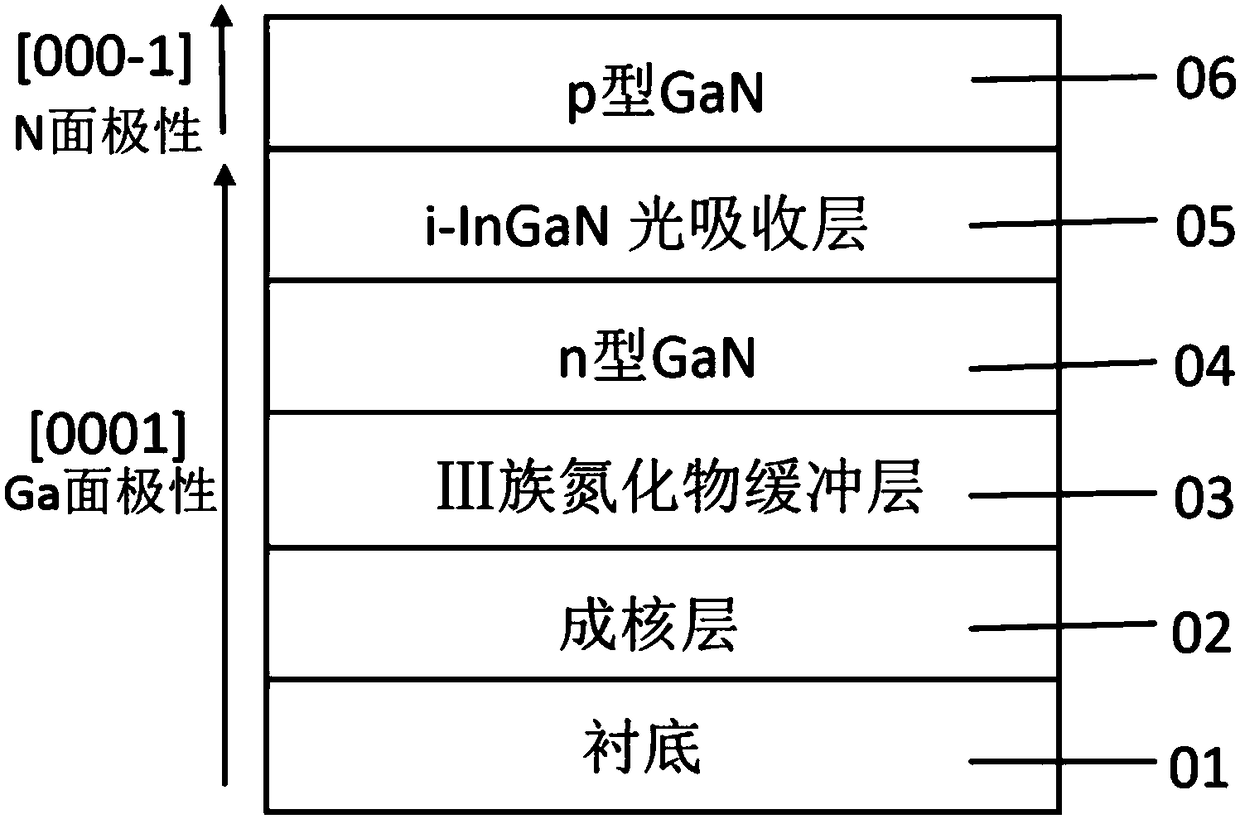

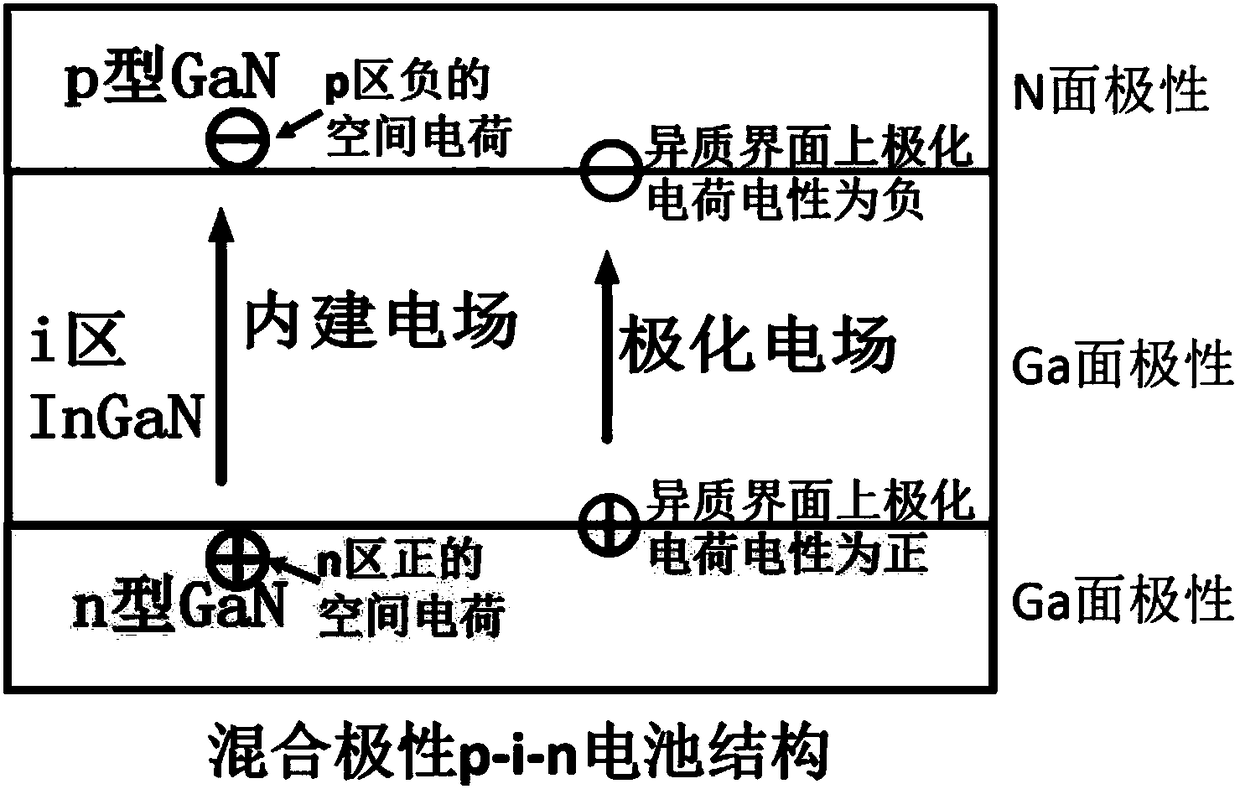

[0040] In this embodiment, a method for preparing a mixed-polarity InGaN solar cell structure is also provided, which specifically includes: sequentially growing a nucleation layer, a III-nitride buffer layer, an n-type GaN layer, and an i-region light layer on a substrate. Absorber layer, p-type GaN layer. Wherein, the polarity of the nucleation layer, the III-group nitride buffer layer, the n-type GaN layer, and the light absorbing layer in the i-region is the Ga plane polarity, and the polarity of the p-type GaN layer is the N-plane polarity.

[0041] Methods for growing various layers of materials on the substrate include but are not limited to metal organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE) and vapor phase epitaxy, and metal organic chemical vapor deposition is preferred. The substrate is preferably a sapphire pattern substrate.

[0042] During preparation,

[0043] The nucleation layer is preferably a GaN nucleation layer, the growth tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com