High-altitude-area carburetor device

A carburetor, high-altitude technology, applied in the direction of machine/engine, etc., can solve problems such as the influence of engine power, and achieve the effect of easy precise control and optimal air-fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

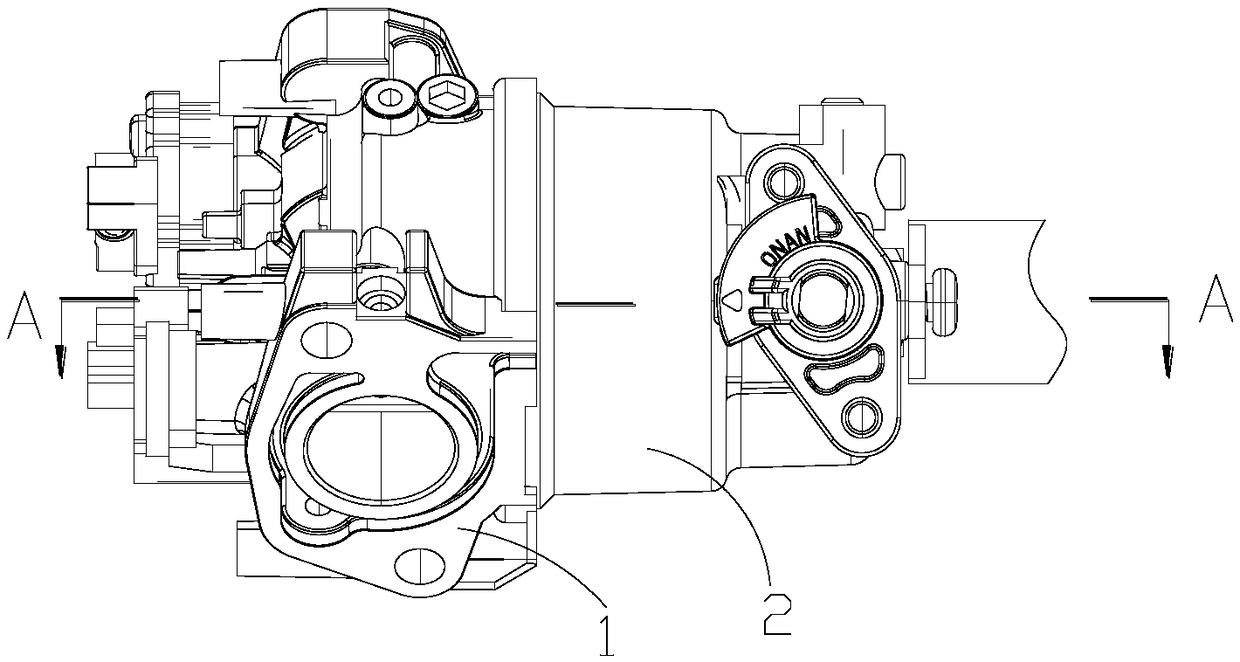

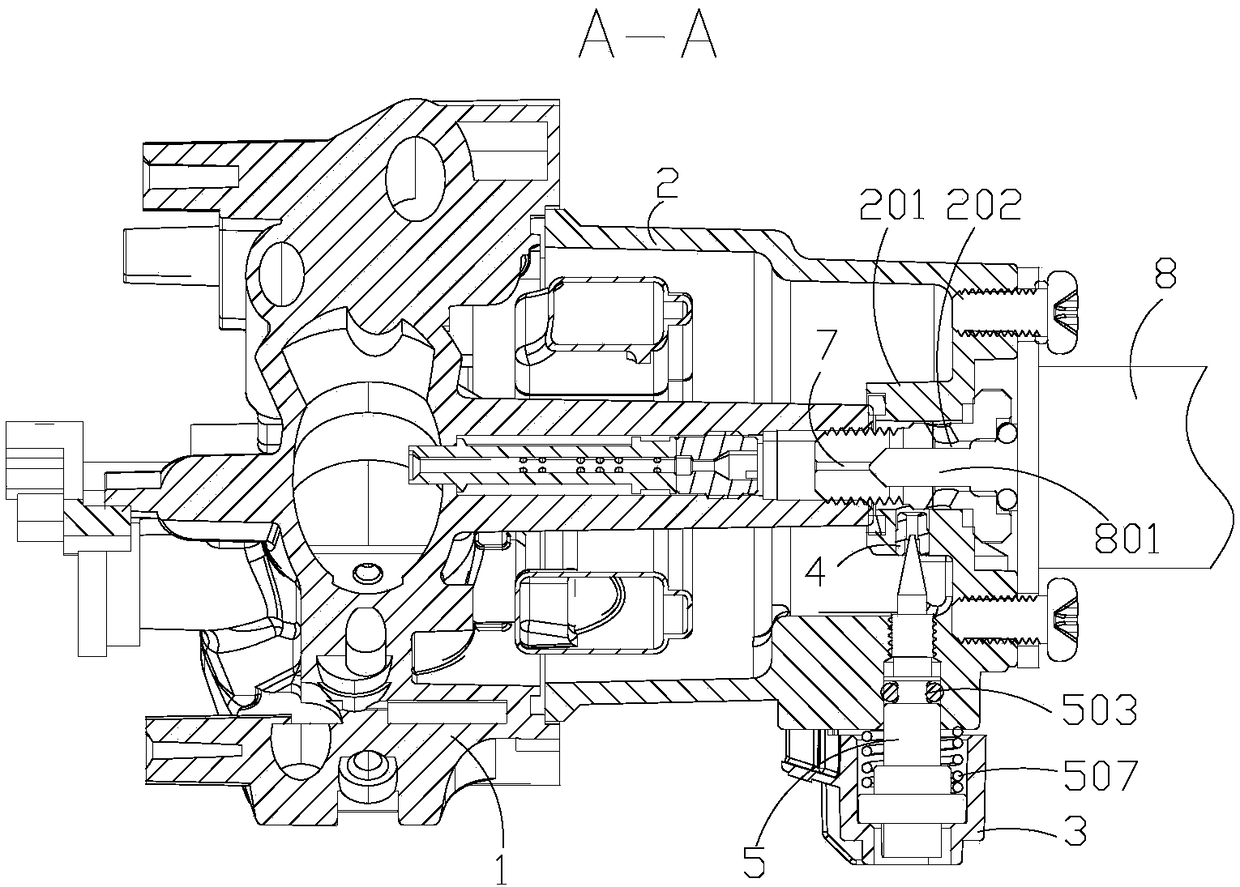

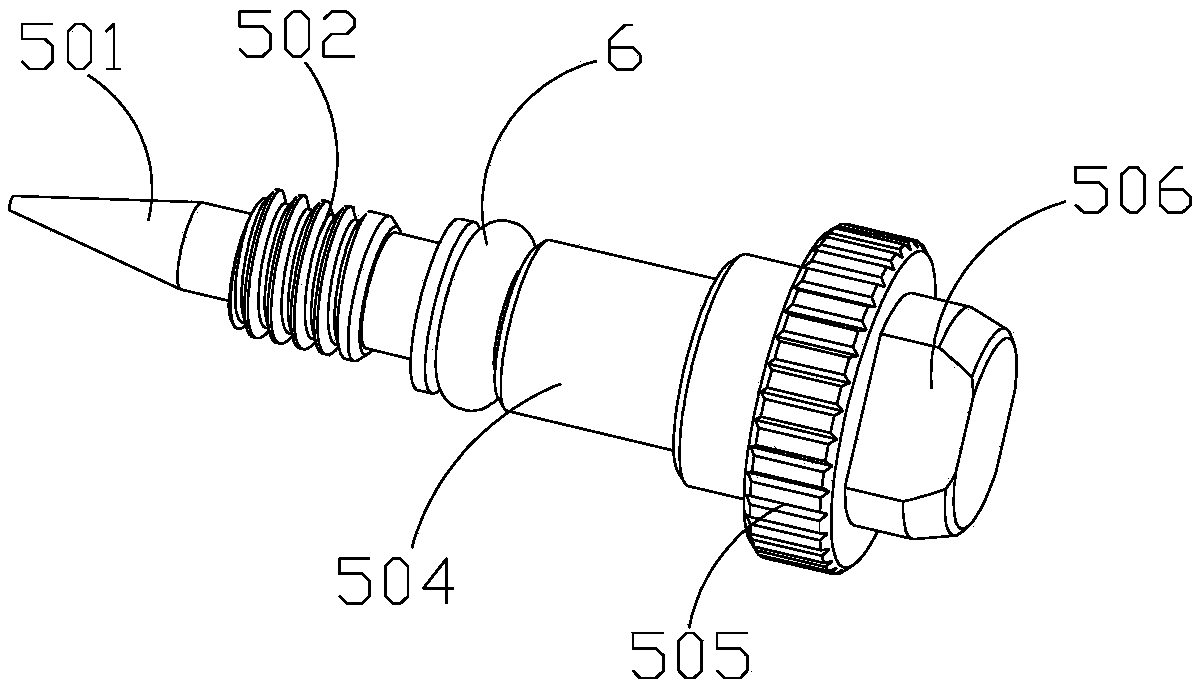

[0020] In the specific use of the present invention, such as Figure 1-4 As shown, a carburetor device in a high-altitude area includes a carburetor body 1. The carburetor body includes a float chamber and a float chamber cover 2. The float chamber is provided with a main metering hole 7, and the inside of the float cover 2 is provided with a protrusion. 201, a channel 202 is provided in the protrusion 201, and a solenoid valve 8 is fixedly provided on the outside of the float chamber cover 2. The output end of the solenoid valve 8 extends to the channel 202 and is connected with a first needle valve 801, and the first needle valve 801 is connected to the main volume The holes 7 match each other; the side wall of the passage 202 is provided with an oil inlet hole 4, and the float chamber cover 2 is also provided with an opening corresponding to the oil inlet hole 4, and also includes a fuel adjustment device, which includes a needle valve part 5, the The needle valve part 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com